Radiographic Testing (RT) for concrete is a non-destructive testing method that utilises radiation sources [X-rays or Gamma rays] to evaluate the internal condition of concrete buildings and structures. This method enables engineers and inspectors to identify internal flaws, such as voids, cracks, or inclusions, without causing any damage to the material. By capturing detailed images of the concrete’s internal features, RT provides important insights into the quality and integrity of the material, facilitating timely maintenance and repair decisions. Its importance lies in enhancing safety, ensuring structural reliability, and prolonging the lifespan of concrete buildings and structures/

Application of Radiographic Testing (RT) for Concrete

- Bridge Inspections: Evaluates the internal condition of bridge components to identify defects, ensuring structural stability and longevity.

- Tunneling Projects: Inspects concrete linings to maintain structural integrity in high-pressure environments.

- High-Rise Buildings: Checks concrete beams, columns, and slabs for defects under significant loads.

- Dams and Water Retaining Structures: Detects internal defects to prevent catastrophic failures in essential infrastructure.

- Industrial Facilities: Inspects concrete foundations and supports to ensure they withstand operational stresses.

- Road and Pavement Assessment: Evaluates concrete roads and pavements for subsurface issues to enhance maintenance strategies.

- Reinforced Concrete Elements: Assesses quality and placement of reinforcements to ensure compliance with design specifications.

Advantages of Radiographic Testing (RT)

- Provides a view of internal structures, revealing hidden defects.

- Capable of detecting small flaws such as cracks and voids.

- Offers detailed information about the condition of concrete elements.

- Applicable to various concrete structures, including bridges, buildings, and dams.

- Provides real-time analysis, facilitating quick decision-making.

- Requires relatively simple equipment and setup compared to other methods.

- Can be performed multiple times on the same structure for ongoing assessment.

- Reduces the need for costly repairs by identifying issues early.

- Aids in meeting safety regulations and standards in construction.

- Enhances quality control during construction and maintenance phases.

- Does not involve harmful chemicals or invasive methods.

- Does not alter or damage the concrete, allowing for continued use after testing.

- Applicable food both precast and post-tensioned elements.

- Conducted in challenging environments, including underwater and high elevations.

- Offers quick analysis and results, allowing for efficient project management.

Prerequisites for Radiographic Testing (RT) of Concrete

- Ensure personnel are trained and certified in RT and radiation safety.

- Verify compliance with local radiation regulations.

- Conduct a site assessment to identify hazards.

- Choose appropriate radiographic equipment for the concrete structure.

- Calibrate equipment per manufacturer guidelines.

- Implement safety protocols, including PPE and shielding.

- Establish a plan for safety and procedure communication.

- Secure the testing area from unauthorized access.

- Prepare detailed testing procedure documentation.

- Check conditions for accuracy, including temperature and humidity.

How Radiographic Testing (RT) Works?

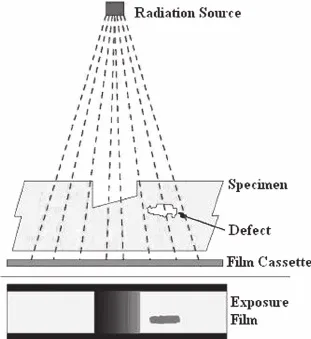

Radiographic Testing (RT) for concrete works by utilizing radiation to produce images of the internal structure of concrete elements. The process involves the following steps:

- Preparation: The concrete structure to be tested is prepared by ensuring a clean surface and removing any obstructions that might interfere with the imaging process.

- Radiation Source: A radiation source, typically X-rays or gamma rays, is positioned on one side of the concrete element. This source emits radiation that penetrates the concrete.

- Image Capture: On the opposite side of the concrete, a detector (film or digital imaging plate) is placed to capture the radiation that passes through the concrete. The amount of radiation that reaches the detector varies based on the density and composition of the concrete, revealing any internal defects.

- Image Processing: The captured image is processed to highlight areas of concern, such as voids, cracks, or irregularities in the concrete structure.

- Analysis: The resulting radiographic images are analyzed by qualified personnel to assess the condition of the concrete. This analysis helps identify potential structural issues and informs maintenance or repair decisions.

- Reporting: A detailed report is generated, summarizing the findings, which can be used for further action, such as repairs or reinforcement.

Equipments and Softwares required for Radiographic Testing (RT) of Concrete

- Radiation Source: X-ray machine or gamma ray source (e.g., cobalt-60).

- Radiographic Film/Detector: Film or digital detectors for capturing images.

- Lead Shielding: Lead sheets for radiation protection.

- Exposure Control: Timers and dosimeters to manage exposure time.

- Mounting Equipment: Frames or supports for stable positioning.

- Protective Gear: Lead aprons, gloves, and goggles for safety.

- Calibration Tools: Calibration sources to ensure proper function.

- Image Processing Software: For enhancing and analyzing images.

Conclusion

Radiographic Testing (RT) for concrete is an essential non-destructive method that uses X-rays or gamma rays to evaluate internal flaws like voids and cracks. By providing detailed insights into the condition of concrete, the method helps in timely maintenance decisions and helps avoid costly repairs.