The concept of using stabilizers for soil stabilization to enhance its bearing capacity evolved from horticultural practices, where stabilizer products were initially used to treat soil for improved plant growth. Over time, this process was adapted and modified to create materials suitable for stabilizing weak soils, especially for road construction. When added to soil, stabilizers increase the wetting and bonding capacity of soil particles, resulting in improved load-bearing properties. These stabilizers are often harmless, cost-effective, and efficient, making them ideal for addressing weak soil conditions.

As population growth continues to strain available resources, it becomes increasingly important to adopt innovative techniques for resource utilization. Civil engineers, in particular, are focused on land stabilization—transforming land with poor engineering properties into stable, usable terrain. This can be achieved through various soil stabilization methods. Stabilization broadly refers to the methods used to enhance soil properties for better engineering performance. It can be classified into two categories: mechanical and chemical stabilization.

Mechanical stabilization involves physical processes such as soil hauling, filling, compaction, and grade improvement to increase stability. In contrast, chemical stabilization involves mixing soil with additives or admixtures that improve its properties, making it more suitable for construction and other engineering applications. By employing these methods, land with weak soils can be converted into stable ground, helping to meet the growing demand for infrastructure and development.

SOIL STABILIZATION

Pavement design relies on the underlying soil strata to provide the necessary structural support for each layer of the pavement system. For this to be effective, the sub-grade soil must be capable of withstanding vehicle loads, minimizing excessive deflections that could lead to fatigue cracking in the layer or the layers above, and preventing excessive permanent deformation due to densification.

As the quality of a soil layer improves, its ability to distribute loads over a wider area increases. This often allows for a reduction in the required thickness of both the soil and the surface layers. Soil stabilization is a key process in achieving these improvements. Stabilization typically enhances soil gradation, reduces the plasticity index or swelling potential, and increases the durability and strength of the soil.

In addition to structural benefits, stabilization also plays an important role in construction, particularly in wet weather conditions. By stabilizing the soil, a solid working platform can be created, enabling construction to continue without delays caused by soft or unstable ground. Overall, soil stabilization is essential for enhancing the performance and longevity of pavement systems.

DIFFERENT PROCEDURES OF SOIL STABILIZATION

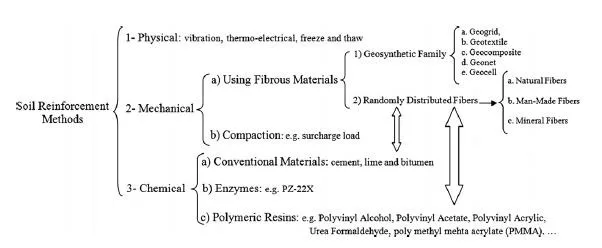

Soil stabilization is a procedure where natural or synthesized additives are used to improve the properties of soils. Several stabilizers available for stabilizing problematic soils. Therefore, the techniques of soil stabilization can be classified into a number of categories with different points of view. Some of the methods appeared in Fig. 1 may have the disadvantages of being ineffective and/or expensive.

STABILIZATION WITH PORTLAND CEMENT

Portland cement can be used either to modify and improve the quality of the soil or to transform the soil into a cemented mass with increased strength and durability. The amount of cement used will depend upon whether the soil is to be modified or stabilized. Portland cement is hydraulic cement made by heating a limestone and clay mixture in a kiln and pulverizing the resulting material.

STABILIZATION WITH LIME

In general, all lime treated fine-grained soils exhibit decreased plasticity, improved work-ability and reduced volume change characteristics. However, not all soils exhibit improved strength characteristics. It should be emphasized that the properties of soil lime mixtures are dependent on many variables. Soil type, lime type, lime percentage and curing conditions (time, temperature,and moisture) are the most important. Lime is a white or grayish-white, odorless, lumpy, very slightly water-soluble solid, CaO, that when combined with water forms calcium hydroxide (slaked lime). Calcium hydroxide is used chiefly in mortars, plasters, and cements. Fly ash is fine particulate ash created by the combustion of a solid fuel, such as coal, and discharged as an airborne emission, or recovered as a byproduct for various commercial uses. Fly ash is used chiefly as a reinforcing agent in the manufacture of bricks, concrete. There are two major classes of fly ash, C and F. Class F is produced from burning anthracite or bituminous coal, it usually has cementitious properties in addition to pozzolanic properties. Class C is produced by burning sub-bituminous coal and lignite, and is rarely cementitious when mixed with water alone.

- Iowa self-cementing fly ashes are effective at stabilizing fine-grained Iowa soils for earthwork and paving operations.

- Fly ash increases compacted dry density and reduces the optimum moisture content.

- Strength gain in soil-fly ash mixtures depends on cure time and temperature, compaction energy, and compaction delay.

- Rapid strength gain of soil-fly ash mixtures occurs during the first 7 to 28 days of curing, and a less pronounced increase continues with time due to long-term pozzolanic reactions.

- Fly ash effectively dries wet soils and provides an initial rapid strength gain, which is useful during construction in wet, unstable ground conditions. Fly ash also decreases the swell potential of expansive soils by replacing some of the volume previously held by expansive clay minerals and by cementing the soil particles together.

- Soil-fly ash mixtures cured below freezing temperatures and then soaked in water are highly susceptible to slaking and strength loss. Compressive strength increases as fly ash content and curing temperature increase.

- Soil stabilized with fly ash exhibits increased freeze-thaw durability.

- Soil strength can be increased with the addition of hydrated fly ash and conditioned fly ash, but at higher rates and not as effective as self-cementing fly ash.

- CaO, Al2O3, SO3, and Na2O influence set time characteristics of self-cementing fly ash.

SCRAP TIRE:

Tire wastes can be used as lightweight material either in the form of whole tires, shredded or chips, or in mix with soil. Many studies regarding the use of scrap tires in geotechnical applications have been done especially as embankment material. Tires have been reused in many different applications mainly related to production of new rubber based materials. Another major form of tire recycling is burning tires for fuel at tire derived fuel (TDF) facilities. There have also been reports that describe construction related applications for waste tires such as crumb rubber modifiers for highway pavement and shredded tires as fill material. The reuse application for tires is dependent on how the tires are processed. Processing basically includes shredding, removal of metal reinforcing, and further shredding until the desired material is achieved.

REVIEW OF SOIL STABILIZATION USING TRADITIONAL AND NON-TRADITIONAL STABILIZERS.

Crumb Rubber With Soil

Shiva Prasad and P.T. Ravichandran had been check the effect of crumb rubber on the behavior of soil they used two different soils and conducted proctor test and unconfined compressive strength test to analyze the MDD and strength values of soil.They used crumb rubber in the range 425 micron to 600 micron and prepared a soil rubber mix of varying crumb rubber percentage (5%, 10%, 15%, and 20 % by weight) results obtained from proctor test shows decrease in MDD and OMC with the increase in crumb rubber percentage this was happened due to lightweight nature of rubber.UCS test showed increase in strength values with increased rubber percentage up to 15% .the percentage improvement in UCS values was 45% for soil S1 up to 10% crumb rubber and 80% for soil S2 up to 15% crumb rubber.

Soil Stabilization WithFlyash And Rice Husk Ash

Er. Jasvir Singh and Er.Harpreet Singh Maan studied the effect of fly ash and rise husk ash on the behavior of locally available clayey soil and evaluate the CBR by using optimum content of fly ash and rise husk ash respectively and also evaluate the UCS by using optimum content of fly ash. They used ranging of FA and RHA from 8% to 24% by wt. of soil (replacing) and found following results

- Soil with varying percentage of fly ash gives maximum CBR value at 8% fly ash. It increased from 3.94 % to 6.8 %. With further addition of fly ash, it keeps decreasing.

- Unconfined compressive strength of soil with 8% fly ash increased as compared to virgin soil from 2.154 kg/cm2 to 2.38 kg/cm2. It was maximum as 4.80kg/cm2 when 24% Paper mill sludge ash was added. After there was decrement in UCS when 26% paper mill sludge ash was added.

- The soil with 8% fly ash was further blended with a variable percentage of rice husk ash (4%,8%, 12%,16% & 20%). The major improvement in CBR occurred at 8% fly ash mixed with 12% rice husk ash and thereafter, further addition of rice husk ash is causing gradual change in CBR values. The peak soaked CBR value is 8.9%.

Stabilization Of Pavement Subgrade Soil Using Cement

G.R. Shiromani Studied the effect of cement on the behavior of sub-grade soil and his study made a comprehensive examination of the effectiveness of cement treatment on geotechnical properties of soils taken from ABU PUR, Modinagar U.P.

- Test results indicate that with the increase in cement content liquid limit, plastic limit and plasticity index decreases as compared to untreated sample.

- Maximum dry density increases while optimum moisture content is reduced with increasing 2%, 4%, and 6% cement with respect to untreated soil samples.

- Test result of direct shear test indicates with increase in cement content the value of cohesion „c‟ decreases and the value of angle of internal friction „Φ‟ increases with every interval of increment of cement.

- California bearing ratio (CBR) of stabilized samples increases sharply with increased cement content. CBR of sample stabilized with 6% cement and compacted of 5 layers with heavy energy of 55 blown in each layers fulfil the criteria proposed by AASHTO soil classification.

Soil Stabilization Using Lime

Ankit Singh Negi,Mohammed Faizan , DevashishPandeySiddharth and Rehanjotsingh had checked the lime effect on behavior of silt or clay soil and summarized the following results.

- Lime is used as an excellent soil stabilizing material for highly active soils which undergo frequent expansion and shrinkage.

- Lime acts immediately and improves various properties of soil such as carrying capacity of soil, resistance to shrinkage during moist conditions, reduction in plasticity index, increase in CBR value and subsequent increase in the compression resistance with the increase in time.

- The reaction is very quick and stabilization of soil starts within a few hours.

- The graphs presented above give a clear idea about the improvement in the properties of soil after adding lime.

Soil Stabilization Using Bio-Enzyme (Terrazyme)

Mr.ShirsathH.A.,Mr.Joshi S.R.,Dr.Sharma V.J. found the following results of Terrazyme stabilizer on engineering properties of soil for 100ml/1.5m3, 200ml/1.5m3 and 300ml/1.5m3 of soil.

- Terrazyme stabilization has shown good modification in index and engineering properties of all three soil (two black cotton soil and one red soil).

- Unconfined Compressive Strength of all three soil has increased with increase of curing time with Terrazyme.

- The properties of all soil have been much improved by stabilizing with Terrazyme dosage of 200ml/1.5m3 of soil. Hence this dosage is considered as the optimum one.

- Compaction characteristics (MDD) are not affected immediately after treatment with Terrazyme.

- Free Swell Index of black cotton soil from sangamner and red soil from surgana reduced with treatment from Terrazyme dosageno especially with drying.

- Terrazyme is found to be ineffective for improving consistency limits.

- The initial cost of using Terrazyme is high as compared to other chemical stabilizer but the benefit of using Terrazyme is that the maintenance cost is zero , making this approach economically cost effective.

SOIL STABILIZATION USING RBI GRADE-81

Neelesh Raghuwanshi, SuneetKaur studied the effect of RBI GRADE- 81 on the engineering properties of soil and accounted following results for its ranging from 2%, 4%, 6% and 8%.

- With the addition of RBI Grade-81 the plastic limit of soil increases and liquid limit of soil decreases and thus plasticity index of soil also decreases.

- MDD decreases and OMC increases with the addition of RBI Grade-81 but the strength does not decrease with decrease of MDD.

- With the addition of RBI Grade-81 and with the increase of curing period duration, the soaked CBR and UCS value also increases.

- According to Tejinder Singh, NavjotRiar (2013) the cost of pavement decreases when RBI Grade-81 is used with soil to construct pavement. The cost of pavement for 2% RBI Grade-81 was found to be minimum among all the other cases of soil and RBI Grade-81 mix.

- With the increase of RBI content, the free swell index of soil decreases.

ADAPTATION IN INDIA

In a developing country like India, stabilizers play a key role in strengthening sub-grade soil, especially given the favorable atmospheric conditions for soil stabilization. Research has shown that using additives like lime and industrial or agricultural waste can significantly enhance soil properties. For example, rice husk ash, an agricultural by-product, can be effectively used for stabilizing soils when combined with cement or lime.

Bio-enzymes, which are organic, non-toxic, and biodegradable, offer a sustainable solution for soil stabilization. These enzymes are safe for humans, animals, and vegetation, making them environmentally friendly. The use of bio-enzymes in pavement construction has been proven to be highly cost-effective compared to traditional methods, contributing to significant savings in construction projects.

Non-traditional additives such as rice husk ash, crumb rubber, marble dust, and blast furnace slag can also improve soil properties, although they are generally less efficient compared to more commonly used stabilizers. However, combining two or more non-traditional additives can enhance their effectiveness. The use of these materials not only improves soil stabilization but also provides an economical alternative while aiding in waste disposal. This dual benefit makes them an attractive option for infrastructure development projects.

As soil stabilizer as they provide an economical alternative and also help in waste disposal.

CONCLUSION

Traditional stabilizers such as fly ash, lime, and cement are well-established methods for enhancing soil properties. However, non-traditional additives like rice husk ash, crumb rubber, bio-enzymes, and RBI Grade-81 also provide effective soil improvement. These alternatives not only enhance soil properties but also offer long-term benefits.

Bio-enzymes, in particular, enable the use of locally sourced materials, potentially eliminating the need for aggregates and reducing overall construction costs. Combining non-traditional additives can further amplify their effectiveness, presenting a promising alternative to conventional methods.

Incorporating non-traditional stabilizers presents a cost-effective and environmentally friendly approach to soil stabilization, supporting better resource utilization and contributing to waste management.

About the author

The author is the Managing Director at Skanda Group of Constructions. He is an experienced Civil Engineer with a demonstrated history of working in the construction industry. He is skilled in AutoCAD, Construction, Management, Concrete, and Structural Analysis.