MIT is leading a transformative approach to construction with its development of 3D-printed glass bricks, expanding the possibilities of sustainable design and technology. As urban populations rise and environmental concerns become more pressing, this innovation provides a vision for the future of construction, where materials are reused repeatedly instead of discarded after a single use. These glass bricks represent a significant shift in building practices, challenging traditional methods by introducing modular blocks that can be assembled and disassembled like Lego pieces.

The Move Towards Circular Construction

The construction industry contributes to nearly 38% of global carbon emissions, an overwhelming figure fueled not just by energy consumption in buildings but also by embodied carbon in construction materials. Embodied carbon refers to the greenhouse gases emitted during the entire lifecycle of construction materials, from production and transportation to assembly and eventual demolition. The current linear construction process, where materials are produced, used, and then discarded—is both wasteful and unsustainable.

Circular construction offers a promising solution. In this model, building materials are designed to be reused indefinitely, minimising waste while maximising their utility. Instead of discarding materials, the end of one building’s life can become the beginning of another. MIT’s 3D-printed glass bricks exemplify this principle, offering a sustainable, innovative alternative to traditional construction materials.

The Breakthrough of 3D-Printed Glass Bricks

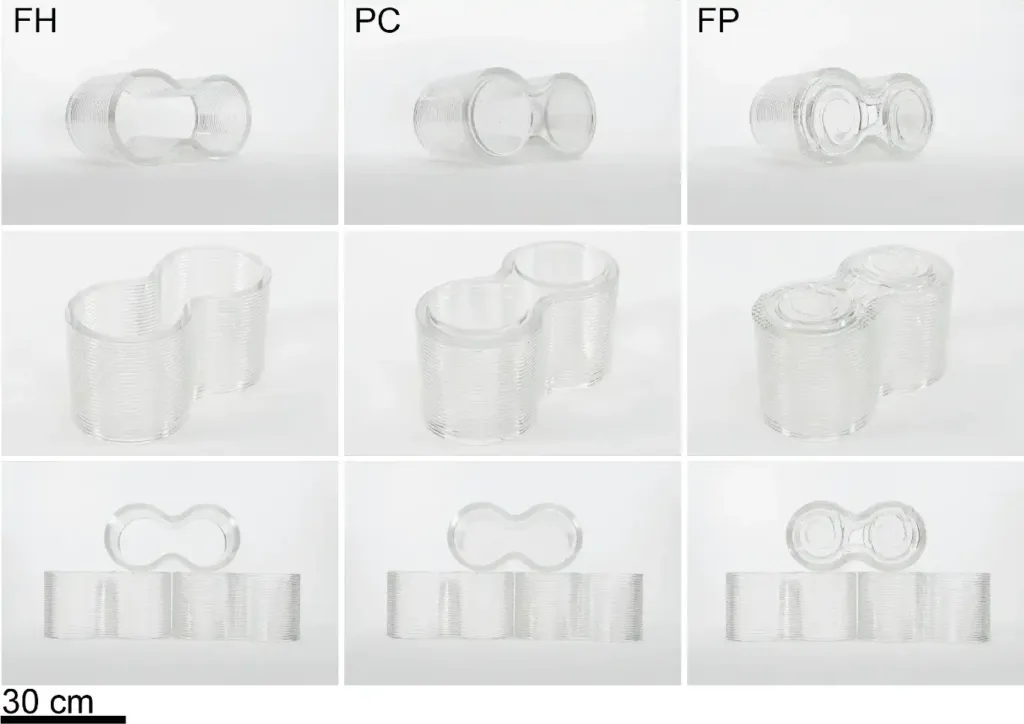

A team of engineers from MIT, in collaboration with Evenline, an MIT spinoff, has developed 3D-printed glass bricks that are both eco-friendly and strong. Each brick has a figure-eight shape and is designed to interlock with adjacent bricks, similar to Lego pieces. This design provides stability and allows for creative architectural features, such as curved walls and detailed facades.

Mechanical tests show that these glass bricks are as strong as traditional concrete blocks, creating new opportunities for flexible and sustainable building designs that are both visually appealing and effective.

Visionaries in Glass Engineering

Leading this innovative project are Kaitlyn Becker and Michael Stern, both of whom have extensive experience working with glass from their time at MIT’s Glass Lab. Becker, now an assistant professor of mechanical engineering, identified glass’s unique potential as a sustainable material. The key advantage of glass is that it can be endlessly recycled, provided it remains pure, which led to the exploration of 3D-printed glass bricks.

“Glass can be reused indefinitely if it’s kept pure,” says Becker, highlighting the material’s extraordinary potential for circular construction.

Stern, the founder of Evenline, saw an opportunity to challenge traditional perceptions of glass. Historically considered too fragile for structural purposes, Stern’s work is demonstrating that glass can be both beautiful and durable, even in large-scale construction projects.

How the Technology Works

The process begins with recycled glass, typically sourced from waste materials like glass The development of 3D-printed glass bricks starts with an innovative recycling process. Recycled glass, typically sourced from discarded bottles, is transformed into durable construction materials.

Process overview

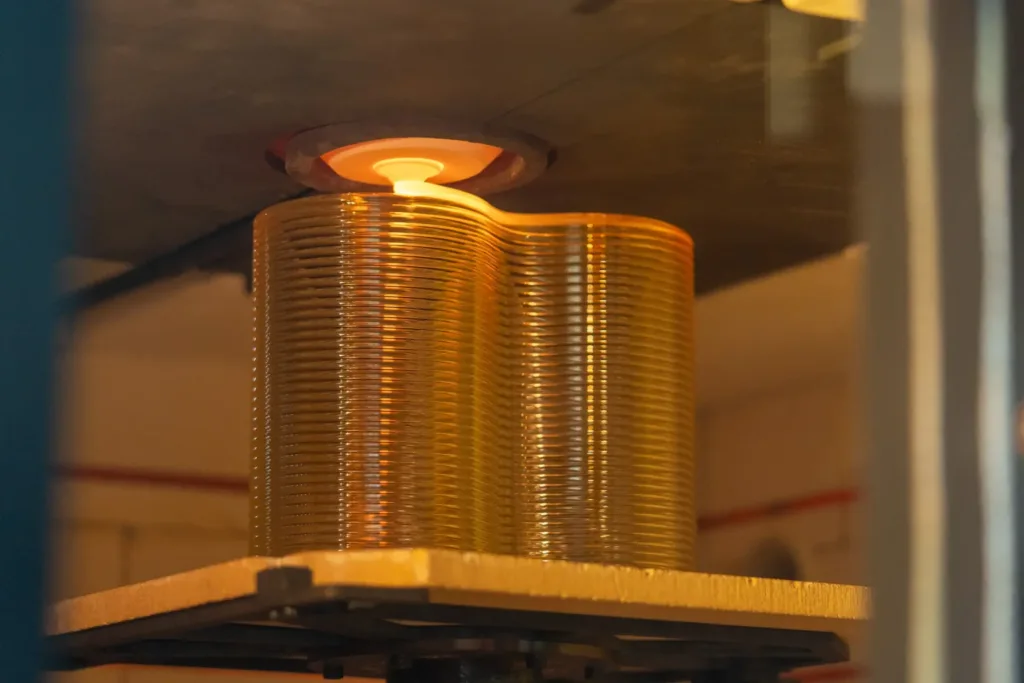

The process begins with recycled glass, melted down in a specialized furnace.

This molten glass is then fed into the Glass 3D Printer 3 (G3DP3), developed by Evenline, which layers the glass to form figure-eight-shaped bricks.

To improve assembly, a separate interlocking feature, made from a different material, is attached to each brick, ensuring easy disassembly and protection of the glass surface.

Extensive mechanical testing proved that despite glass’s inherent brittleness, these bricks are as strong as conventional concrete blocks, making them viable for construction projects.

Environmental and Architectural Impact

The environmental benefits of 3D-printed glass bricks are substantial:

- Use of Recycled Materials: By using recycled glass, the process reduces the need for new raw materials, which in turn lowers greenhouse gas emissions related to production.

- Circular Construction: These bricks fit perfectly into the model of circular construction. Their ability to be disassembled and reused makes them ideal for a rapidly changing world, where buildings may need to be adapted or relocated without producing waste.

- Minimized Carbon Footprint: Glass recycling also reduces the embodied carbon associated with traditional construction materials, significantly lowering the overall carbon footprint.

Architecturally, the transparency and beauty of glass present exciting possibilities. The figure-eight design of the bricks allows for both functional and aesthetic versatility, making it possible to construct light-filled, open spaces that are visually stunning while maintaining structural integrity.

The Future of 3D- Printed Glass in Construction

The team at MIT envisions significant scaling potential for 3D-printed glass bricks. They plan to start by constructing pavilions to demonstrate the versatility of these bricks, with the long-term goal of integrating them into larger buildings.

In the future, we may see entire buildings constructed from materials that can be endlessly reused and adapted, reducing waste and conserving resources. The ability to create modular, customizable structures opens new avenues for architectural creativity. Glass, often thought of as fragile or purely decorative, could become a cornerstone of sustainable building design.

Conclusion

MIT’s 3D-printed glass bricks mark a significant advancement in construction, blending sustainability, design, and technology. With the construction industry facing increasing environmental challenges, innovations like these offer a promising path forward. The potential for recyclable, durable, and visually distinctive building materials could transform our cities, making them more adaptable, resilient, and sustainable for future generations.

Image Source: parametric-architecture.com, designboom.com, interestingengineering.com