Woven wire mesh is a type of mesh in which a number of metal wires are interlaced together to form a roll or sheet of wire cloth. The woven wire mesh’s diameter, opening, size, micron weave pattern, width, and length can be customized to your specific needs. Woven wire mesh can be manufactured faster and is economical. It can be manufactured in different sizes and is dependent on the required wire thickness in relation to aperture size. It can vary in texture from being as flexible to rigid. Woven wire meshes can be manufactured with a variety of materials.

Materials for woven wire mesh

Function, stability, and efficiency of woven wire mesh can be met by different materials, depending on the project. The following materials are used to weave wire mesh:

- Steel: blank, galvanized, tinned, lacquered, plastic-coated

- Stainless steel: chrome-nickel steel, chrome-nickel-molybdenum steel etc.

- Non-ferrous metals Aluminum, nickel, brass, copper etc.

- Special materials: Titanium, Hastelloy, silver, platinum etc.

How is woven wire mesh manufactured?

Woven wire mesh is manufactured using a specialized weaving loom. The method is as followed:

- A number of wires are wrapped around a warp beam that is placed on weaving looms

- The wires that are wrapped are slowly placed into heddle frames that divide them into to a number of sets according to weave/pattern of the mesh requirement

- As the loom becomes operational, the heddle frames push the different sets of wires up and down

- After being threaded through the wires, the heddle frames lock the shutter wire into place.

- The method is repeated until the specified measurements are achieved, and the finished wire mesh sheet is cut into particular sizes

Different types of woven wire mesh

Discussed below are different types of woven wire mesh that are manufactured and used across different applications.

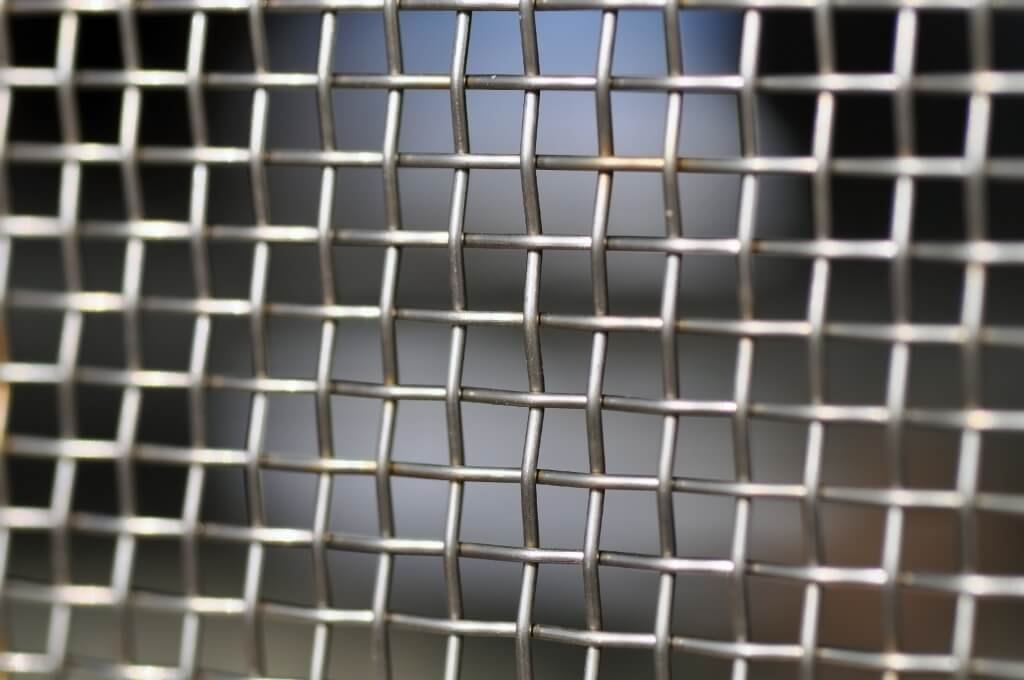

Plain Woven Wire Mesh: Manufactured with a plain weave formed with straight warp wires. In this type of woven wire mesh, warp wires and weft wire pass alternately over and under each wire strand, and vice versa.

Lock Crimp Woven Wire Mesh: Manufactured with straight sections of wire connected by a ‘bump’ at the wire intersections, that lock the wires together.

Twill Woven Square Wire Mesh: In this type of woven wire mesh each warp wire and each weft wire passes over and under the next two adjacent complementary wires, which is similar as twill weave. This type of wire exhibits a parallel and diagonal pattern.

Twill Dutch Woven Wire Mesh: exhibits superior strength, which is due to the weaving of a high volume of wire in targeted areas of the weave.

Reverse Plain Dutch Woven Wire Mesh: Manufactured using large warp wire and smaller shute wire count.

Dutch Plain Dutch Woven Wire Mesh: This type of mesh mechanical strength and is used in industrial filtering where a high rigidity of the mesh is required.

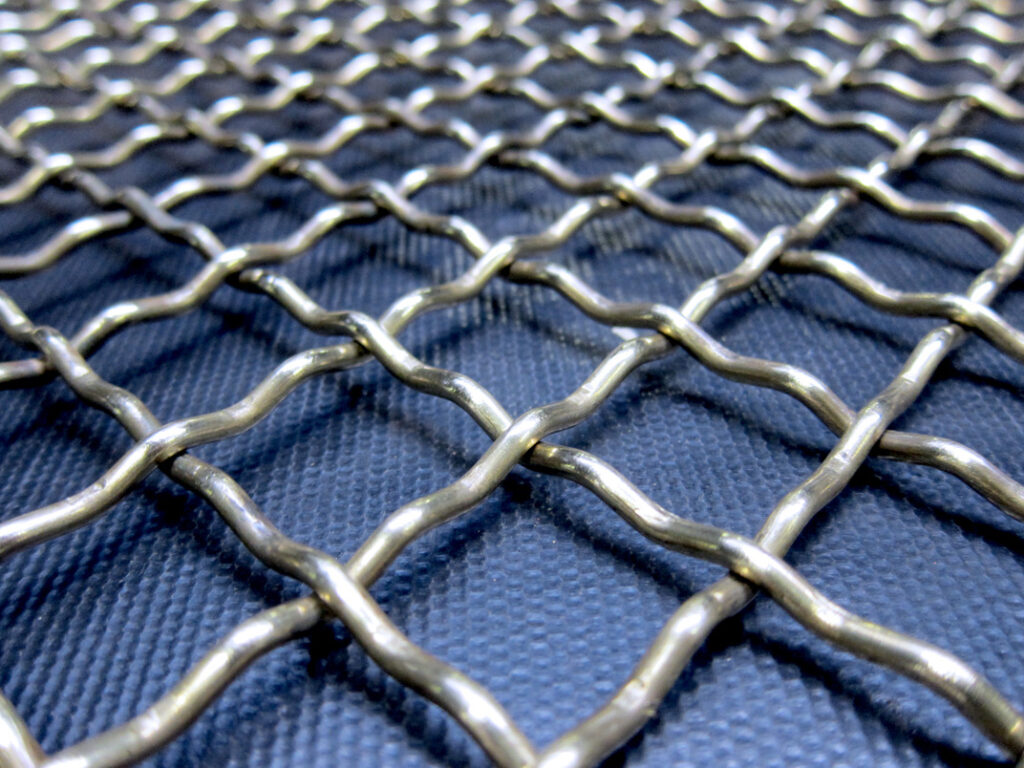

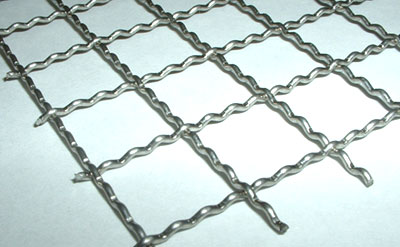

Pre-Crimped Woven Wire Mesh: In this type, the weave ends are crimped before they are weaved. The crimps are made at the points where the shute and warp wires intersect, stabilizing the wire cloth and preventing the wire from moving.

Crimped Woven Wire Mesh: Manufactured by weaving pre-crimped wires. The crimped woven wire mesh has a square and rectangle opening, which comes in different wire diameters.

Inter-Crimp or Multiple Crimp Woven Wire Mesh: In this type of woven wire mesh both the warp and shute wires are crimped with added crimps between the points of intersection.

Woven wire mesh products

Woven wire mesh is widely used in interiors and exteriors for decorative enhancements and functionality. The woven wire mesh products allow you to enhance your project cost-effectively. It can be used outdoors not only for durability, but also for excellent corrosion resistance, especially in humid environments and near the seaside. Custom weaves from a wire form manufacturer can provide strength for safety as well as security and insulation for sound-dampening applications. It can be easily fabricated and shaped to meet the design requirements of your project. Discussed below are different types of

woven wire mesh products.

Woven wire mesh screen

Woven wire mesh screen is manufactured using various weaving methods, such as double crimped, flat top crimped, intermediate crimped and lock crimped. Wire mesh screens can be used to keep out unwanted things like insects. But they can also be used for netting purposes to protect human beings from falling masonry from old buildings or from rock falls.

Woven wire mesh filters

Woven wire mesh filters are extremely versatile and are used in almost every industry.Wire meshes are used to make filter elements ranging from simple strainers to complex pleated filters.They can have various end connections, such as double open ends, single open ends with threaded ends, etc. These are used in Refineries and Petrochemicals Power Plants, Water filtration and Cooling Towers, Chemical Industries Steel Industries, etc.

Woven wire fence

Woven fences are fences made from Woven Mesh and depending upon the pattern of weaving can be in diamond or hexagon shape. These fences are designed to provide strong demarcation to the perimeter and are more cost-effective than most fencing solutions. Easy installation & multiple coating options make it suitable for several applications like Solar farms, Residential complexes, Seaports and Airports

Woven wire mesh infill panels for railings

Woven wire mesh infill panels provide an upscale look that’s preferred in residential and architectural installations. Woven wire mesh infill features an organic, interwoven fabric as an infill. Mesh infills are timeless and easy to maintain. The signature box frame completes the system for a clean, sharp look. Available in a wide range of standard designs, with options of custom design and materials. Woven Wire infill panels work well as a protective barrier in high traffic areas such as schools, zoos, parks, restaurants and jogging paths.

Woven Wire Mesh Partition

Woven mesh can be welded inside sturdy angle frames to create a single wire partition panel that’s bolted to square steel tubing posts to create a strong and rigid modular wall or enclosure. With different stock wire partition panels and stock posts, you can design almost any wire partition system to meet your needs

Woven gabion wire mesh box

Mesh Gabions are rectangular wire mesh baskets filled with rock. It is a rectangular wire mesh box consisting of three one half turns to form hexagonal shaped mesh openings of Zinc galvanized and PVC coated steel wire. These mesh openings are then interconnected with adjacent wires to form hexagonal meshes.It is used at the project site to form malleable, permeable,monolithic structures such as retaining walls and structures for various types of civil projects.

Woven wire Chain Link Fence

Woven wire chain link fence is made from steel (GI) wire. It is one of the most traditional and versatile forms of wire fencing used in areas that need enhanced protection from intrusion like Garden fences, Factory usage, Home usage, and Tennis court.

Conclusion

Discussed above are the different advantages, types, and products of woven wire mesh. In an upcoming article, we will discuss other available products and applications of woven wire mesh products.