Vinylester-based anchors are composed of high-strength vinylester resin, providing durable anchoring for concrete, masonry, and steel structures. They offer strong adhesion, high load capacity, and resistance to chemicals, moisture, and temperature changes. With excellent corrosion resistance, they ensure long-term performance in demanding environments, making them a reliable choice for secure and lasting installations.

Applications of Vinylester- based anchors

- Structural Anchoring – Used for securing steel columns, beams, and heavy load-bearing elements in buildings and bridges.

- Seismic Retrofitting – Enhances the structural stability of buildings and infrastructure in earthquake-prone areas.

- Bridge Construction & Repair – Provides high-strength anchoring for bridge decks, guardrails, and expansion joints.

- High-Rise Buildings – Ensures reliable fastening for curtain walls, façades, and reinforcement bars in skyscrapers.

- Tunnel & Underground Structures – Used for rock bolts and reinforcement in tunnels, metro systems, and underground facilities.

Advantages of Vinylester- based anchors

- Provides superior anchoring performance for heavy-duty applications.

- Ensures quick installation and reduces downtime.

- Bonds strongly to concrete, masonry, and other substrates.

- Withstands exposure to harsh chemicals, making it ideal for industrial environments.

- Performs well in wet or humid conditions, including marine and underground applications.

- Offers long-term durability in aggressive environments.

- Maintains performance under varying temperatures.

- Suitable for earthquake-prone regions due to high flexibility and strength.

- Provides secure anchoring in dynamic load conditions such as bridges and highways.

- Applicable for new construction, retrofitting, and repair projects.

- Reduces the risk of substrate cracking, unlike mechanical anchors.

- Ensures durability and reliability over extended periods.

Types of Vinylester- based anchors

1. Vinylester Chemical anchors

Vinylester chemical anchor anchors use a two-component resin and hardener system to create strong, reliable bonds. These anchors are used in securing steel plates to concrete bridge decks, stabilizing tunnel linings, and reinforcing high-rise foundations. Their fast-curing properties allow for quicker installations, minimizing downtime in large-scale projects. Additionally, their resistance to moisture, chemicals, and temperature variations makes them suitable for highways, metro rail systems, and offshore structures.

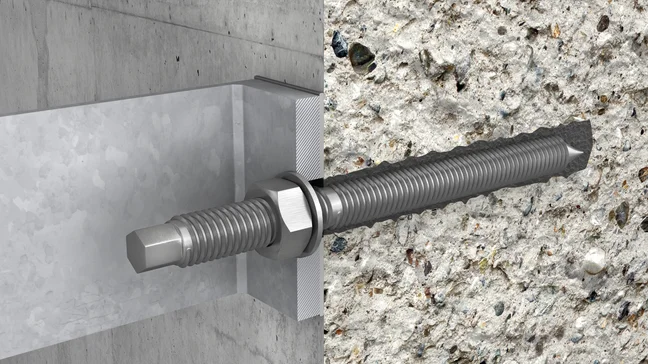

2. Vinylester Threaded Rod anchors

Threaded rod anchors with vinylester resin are commonly used in construction to anchor heavy structural components such as steel beams, guardrails, and precast concrete panels. Their high pull-out strength ensures strong connections in bridges, stadiums, and commercial buildings. These anchors perform well under dynamic loads, making them suitable for seismic zones and wind-prone areas. Their resistance to corrosion also makes them a preferred choice for structures exposed to coastal environments and industrial pollutants.

3. Vinylester Rebar Doweling anchors

Vinylester-based rebar doweling anchors help extend and strengthen reinforced concrete structures. They are used in bridge widening projects, tunnel reinforcements, and high-rise construction to ensure strong adhesion between old and new concrete elements. These anchors improve stability in applications such as retrofitting columns, securing crash barriers, and reinforcing earthquake-resistant structures. Their ability to bond effectively in both dry and damp conditions makes them suitable for underground and marine infrastructure projects.

4. Vinylester Stud Anchor anchors

Stud anchor anchors with vinylester resin are designed for securing heavy loads in structural applications, including bridge anchoring, tower foundations, and industrial plant installations. These anchors provide high tensile and shear strength, making them reliable for transmission towers, railway bridges, and hydroelectric dams. Their resistance to vibration and impact loads makes them effective for metro rail projects and airport terminals. The chemical-resistant nature of vinylester resin enhances their durability in settings such as wastewater treatment plants and petroleum refineries.

5. Vinylester Hybrid anchors

Hybrid anchors, combining vinylester resin with additional strengthening agents, are designed for construction and infrastructure projects that require enhanced performance. They are used in fire-resistant applications, seismic retrofitting, and underwater construction. These anchors are commonly applied in tunnel reinforcements, nuclear power plants, and high-rise building foundations, where durability and long-term performance are key factors. Their ability to cure in damp and submerged conditions makes them well-suited for coastal infrastructure, port facilities, and dam reinforcements.

How to Choose the Right Vinylester- based anchor?

- Load Requirements – Select based on tensile and shear strength needed.

- Substrate Type – Choose suitable anchors for concrete, masonry, or brick.

- Environmental Conditions – Use corrosion-resistant for harsh environments, fire-resistant for high temperatures, and underwater-grade for wet conditions.

- Installation Method – Opt for capsule anchors for precision, cartridge systems for convenience.

- Cure Time & Temperature – Fast-curing for quick projects, low-temp-rated for cold conditions.

- Seismic & Dynamic Loads – Use seismic-grade anchors for earthquake-prone or high-vibration areas.

- Code Compliance – Ensure certification (ETA, ASTM, ICC-ES) for safety and regulations.

- Application Type – Choose based on new construction, retrofitting, or repairs.

Application Method for Vinylester- based anchors

- Surface Preparation – Clean the substrate, ensuring it is dry and free from dust or debris.

- Drilling the Hole – Use a rotary hammer drill to create a hole of the specified diameter and depth.

- Cleaning the Hole – Remove dust using a hand pump, brush, or compressed air for better adhesion.

- Injecting the Resin – Dispense vinylester resin into the hole, ensuring even distribution without air pockets.

- Inserting the anchor – Insert the threaded rod, rebar, or anchor, rotating slightly for proper bonding.

- Curing Time – Allow the resin to set as per manufacturer guidelines before applying load.

Conclusion

Vinylester-based anchors provide efficient and reliable anchoring for various construction and infrastructure applications. Their versatility, ease of installation, and durability make them a preferred choice for securing structural elements in demanding environments.