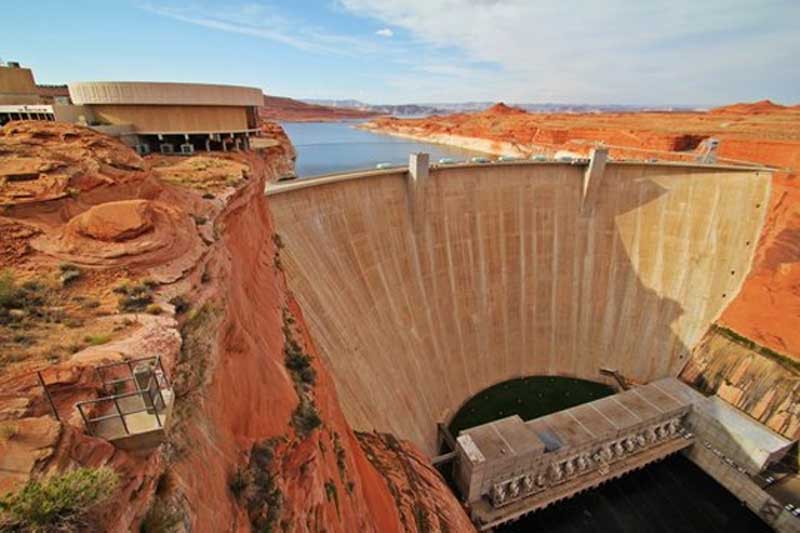

Arch dams are a type of dam characteriSed by their curved shape, which enables them to withstand the hydrostatic pressure exerted by the reservoir water. They are constructed with the purpose of holding back large volumes of water, typically for purposes such as flood control, water conservation and hydroelectric power generation. The arch shape of the dam allows it to transfer the water pressure to the abutments on either side of the structure, which then bear the weight of the water and provide stability.

Arch dams are primarily constructed using concrete due to its strength, durability, and ability to withstand water pressure. The concrete is typically reinforced with steel bars (rebar) to enhance its tensile strength and structural integrity. In some cases, other materials such as rock fill or asphalt concrete may be used for specific components of the dam, such as the upstream face or the spillway, to provide additional stability or erosion resistance.

Structural parts of Arch Dams

- Foundation: Provides support and stability by transferring the dam’s weight to the bedrock or stable soil.

- Abutments: Solid structures at the ends of the dam that resist lateral forces and support the structure.

- Spillway: Controls the release of excess water to prevent overtopping and flooding.

- Crest: The top of the dam where water flows over or through during normal operation.

- Buttresses: Reinforced concrete supports on the downstream side that resist water pressure and stabilize the dam.

- Arch: Curved portion of the dam that transfers water pressure to the abutments.

- Galleries: Enclosed passages within the dam used for inspection, maintenance, and sometimes as conduits for water or power generation.

Types of Arch Dams

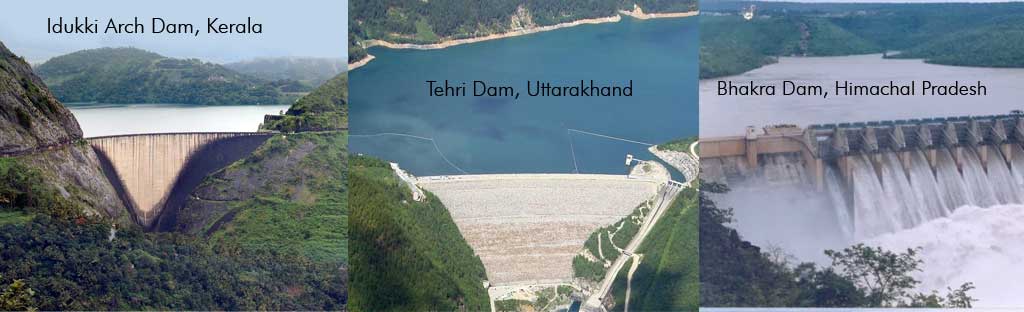

1. Single-Curved Arch Dam: Single-curved arch dams have a simple, single curved shape resembling a crescent moon when viewed from the side. They rely on their curved shape to efficiently transfer water pressure to the abutments on either side of the dam. This type of arch dam is commonly used for medium to large reservoirs and offers a good balance between construction complexity and structural efficiency. Single-curved arch dams are suitable for a wide range of geological conditions and can be constructed using various materials such as concrete and steel reinforcement.

2. Double-Curved Arch Dam (Multiple-Arch Dams): Double-curved arch dams, also known as multiple-arch dams, consist of a series of arches arranged in a radial pattern. This design allows for better distribution of forces and can provide increased stability compared to single-curved arch dams. Multiple-arch dams are often used for larger reservoirs or in areas with complex geological conditions where the forces acting on the dam need to be carefully managed. While they may require more intricate construction techniques, multiple-arch dams offer enhanced structural performance and can be tailored to specific site requirements.

3. Constant-Angle Arch Dam: Constant-angle arch dams are a variation of single-curved arch dams characterized by a constant angle profile along the length of the dam. This design simplifies construction and allows for a uniform distribution of forces. Constant-angle arch dams are commonly used for reservoirs where a straightforward and efficient dam design is desired. They offer good structural stability and can be constructed using standard construction techniques, making them cost-effective for a wide range of applications.

4. Variable-Radius Arch Dam: Variable-radius arch dams are another variation of single-curved arch dams, featuring varying radii along the length of the dam. This design allows for more precise control over the distribution of forces and can optimize the structural performance of the dam. Variable-radius arch dams are often used in situations where the reservoir geometry or geological conditions require a more tailored approach to dam design. While they may require more complex construction techniques, variable-radius arch dams offer the potential for improved efficiency and stability.

5. Thin Arch Dam: Thin arch dams are characterised by a relatively thin cross-section compared to other types of arch dams. They are typically used for smaller reservoirs or in situations where space is limited. Thin arch dams offer a compact and efficient design while still providing adequate strength and stability to withstand water pressure. Due to their smaller size and simplified construction, thin arch dams can be cost-effective for a range of applications, including irrigation, flood control, and water supply.

How to select the right Arch Dam type?

- Evaluate geological, hydrological, topographical, and environmental factors.

- Consider structural, hydraulic, and stability needs of the project.

- Assess logistical, material, labour, and budgetary limitations.

- Identify potential risks, including seismic hazards and environmental impacts.

- Define lifespan, maintenance, and operational efficiency requirements.

- Seek input from various specialists, including structural and geotechnical engineers

- Ensure adherence to regulatory standards for safety and environmental protection

How is the arch dam constructed?

1. Site Preparation:

- Clear the construction site of vegetation, debris, and topsoil.

- Excavate the foundation area to expose the bedrock or stable soil.

2. Foundation Construction:

- Prepare the foundation surface and ensure it is properly leveled and compacted.

- Place a layer of bedding material if needed to enhance stability.

- Pour concrete to form the base of the dam, ensuring it is properly aligned and compacted.

3. Formwork Installation:

- Install formwork, or molds, to define the shape of the dam.

- Ensure the formwork is securely anchored and aligned according to design specifications.

4. Concrete Pouring:

- Pour concrete into the formwork in layers, or lifts, ensuring proper consolidation.

- Use vibration equipment to remove air pockets and ensure uniform compaction.

5. Reinforcement Installation:

- Place steel reinforcement bars (rebar) within the concrete, following engineering specifications.

- Tie rebar together to form a grid-like framework for structural strength.

6. Curing and Strength Development:

- Allow the concrete to cure and gain strength over time.

- Maintain appropriate curing conditions, such as moisture and temperature control, to facilitate hydration.

7. Formwork Removal:

- Once the concrete has sufficiently cured, remove the formwork carefully to avoid damaging the structure.

- Inspect the surface of the dam for any defects or imperfections and address them as needed.

8. Ancillary Structures:

- Construct ancillary structures such as spillways, outlets, and intake towers to support dam operation.

- Install galleries or access tunnels for inspection, maintenance, and operation purposes.

9. Testing and Commissioning:

- Conduct tests to verify the structural integrity, stability, and functionality of the dam.

- Perform hydraulic performance tests, safety inspections, and other necessary evaluations.

- Once the dam is deemed safe and operational, commission it for use.

Throughout the construction process, ensure adherence to safety protocols, environmental regulations, and quality control measures to achieve a successful and durable arch dam.

Conclusion

Arch dams, distinguished by their curved configuration, are vital infrastructure assets known for their capacity to withstand immense hydrostatic pressure exerted by reservoir water. From single-curved to variable-radius designs, each variant is meticulously engineered to address diverse geological and operational requirements. The selection process entails a comprehensive evaluation of geological, hydrological, and environmental factors, coupled with expert consultation to ensure adherence to safety and regulatory standards. During construction, meticulous attention to detail, rigorous quality control measures, and strict adherence to safety protocols are paramount to ensure the longevity and effectiveness of these critical structures, which play important roles in flood control, irrigation, hydroelectric power generation, and water resource management.