A big part of the construction is hauling things around like rock, dirt, material, and equipment. There are many kinds of hauling equipment you will find on construction sites. The right hauling equipment plays a key role in the construction and has to transport heavy and oversized loads. To be able to haul large and heavy loads, it will require the use of hauling equipment in the construction industry. Having heavy hauling equipment at the worksite on time is important for the success of any construction job. These are used for hauling units to transport the earth, aggregate, rock, ore, coal and other materials. Given below is an overview of the types of hauling equipment commonly used in construction and more:

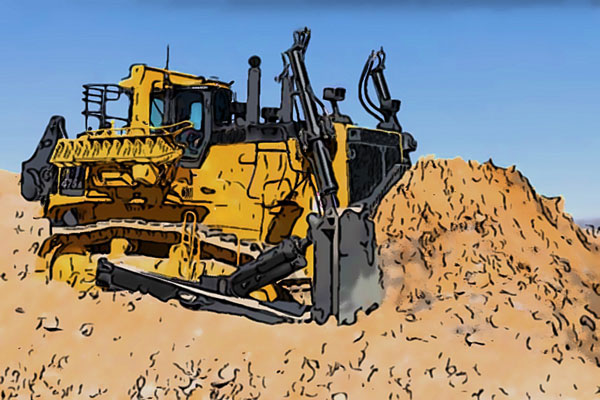

Bulldozers

The modern bulldozer model is designed for tough mining and extraction operations and provides sufficient power to contend with any situation. The hydrostatic travel drive in the bulldozer operates smoothly and automatically adjusts the working speed to the load conditions. The torque is constant on both tracks without interruption. This allows exact and powerful steering. When working in narrow areas, the hydrostatic travel drive offers an additional benefit. All steering motions – including turning on the spot – are fast and precise. When involved in ripping work, the ripper can be positioned precisely to enable it to apply great power when ripping layers of hard rock. Bulldozers can be found on a wide range of sites, mines and quarries, military bases, heavy industry factories, engineering projects and farms. Modern bulldozers are built to withstand the incredible stresses of today’s mine operations while achieving the production levels that mining company bottom lines demand. High tractive effort and the low drive, K-bogie undercarriage system make these bulldozers incredible ripping machines. Using high production Sigma blades or inside-mounted six-way blades, these bulldozers are versatile enough to accomplish those tasks and so much more. And now, built-in intelligence is available so you can work flawlessly with leading GPS grade control systems.

Excavators

Modern hydraulic excavators come in a wide range of sizes. The new hybrid models now manufactured has the lowest ever fuel consumption and has also been designed to further reduce CO2 emissions and running costs. Incorporating proven technology, an advanced hydraulic system and a new lightweight arm, it achieves this without compromising on high levels of performance and easy operation. One of the key benefits of hydraulic machinery is the ability to achieve motion via hydraulic actuators such as cylinders and swing motors. And when hydraulics are combined with modern technology such as grade control, laser positioning, and GPS, the potential seems almost endless. Manufacturers are also incorporating more sophisticated hydraulic functions that allow the operator to adjust hydraulic flow to the application. The new range of mini excavator models features a full-rotation (FR) design. This enables to dig offset to the right or left without needing to reposition the machine, and it allows more of the counterweight to remain in line with the center of the machine for greater stability. An available cab provides an automotive-styled interior equipped with an optional air conditioner, defrost, windshield wiper and washer, skylight with sunshade, Bluetooth radio, and a high back suspension seat with headrest.

Cranes

Crane manufacturers are expanding their product range and introducing advanced features for higher lifting capacity and greater safety, to meet the demand coming from infra development projects across India. With the growth in the size of projects, primarily the ultra mega power projects, there is a definite indication of demand graduating to higher capacity crawler cranes from the Indian construction sector. Newer models now come with smart mechanised solutions for mobile cranes. From workstation lifting systems to industrial needs, mole cranes are offering Smart Features for projects. Hybrid overhead travelling cranes can be loaded with smart features that give you control of the material handling in your production processes. New models are simplified fly assembly with new ground-level carrier controls. In construction, the two basic types of cranes are mobile and fixed. Mobile cranes consist of trusses mounted onto mobile platforms, such as trucks or flatcars. Fixed cranes can lift heavier loads and have better reach due to their increased stability. Tower cranes, used in high-rise building construction, are an example of a fixed crane mounted on top of a steel tower. Latest range of crane is designed for a range of tasks, including alternative energy applications, road and bridge construction, and utility and barge work. The crane is enhanced with the optional personnel basket attachment with radio remote control. Its five-section main boom producing an impressive maximum tip height bifold offsettable swing away boom extension is added. Modern crane is compact and highly maneuverable with robust construction and high torque multiplicity, which make them performance-worthy for rough terrains and applications. This means that they can get into tighter spaces. Outriggers provide stability for lifting operations and, by using a hydraulic boom and hoist, rough terrain cranes can lift heavy loads to exceptional heights. Most rough terrain cranes have 4-wheel drive to better navigate off-road

Wheel Loaders

The wheel loader models are coming out with a variety of features and bucket size enhancement based on application and customer requirements. The wheel loaders are also incorporating the unique Hydrostatic technology in which the power is transferred from the engine to the axle via hydraulic motors. The most striking advantage of this technology is increased efficiency, which directly translates to higher fuel efficiency. Telematics in wheel loaders is also giving owners access to machine monitoring information that helps save time and money. The system generates reports on fuel consumption, operational hours, geographical location and more. The manufacturers of wheel loaders are also offering variable bucket capacities ranging from 2.2 m3 to 12.7 m3, along with attachment brackets, loader buckets, forks, material handling arms, grapples, and log pushers. Buckets are also designed and shaped for efficient scooping-up and loading. Modern wheel loaders come with centralized hydraulic pressure measuring points for easy checks and troubleshooting. These models come with variable displacement pumps and with different types of mode selectors [Automatic, Semi-Automatic and Manual] which make them more productive and fuel-efficient. The optimized design of the buckets provides a greater loading capacity and lesser operating cycle time with the synchronized flow. Pilot control single lever makes the machine easy to operate. The machines are also equipped with GPS which provides accurate data which helps the owner evaluate the performance of the machine. Added to the loading usefulness is that the machine comes with a long lifecycle and low operating costs.

Dump trucks

A dump truck, known also as a dumper truck or tipper truck, is used for taking dumps (such as sand, gravel, or demolition waste) for construction as well as coal. A typical dump truck is equipped with an open-box bed, which is hinged at the rear and equipped with hydraulic rams to lift the front, allowing the material in the bed to be deposited (“dumped”) on the ground behind the truck at the site of delivery. Dump trucks come in an assortment of types and configurations, with each designed for use across a variety of different applications, so picking the right one for your project or operation is important. Popular applications include using articulated dump trucks for civil and mining operations, rigid rear dump trucks for use in tandem with hydraulic excavators in mining, site dumpers and front tippers for use in compact or low capacity operations, track mounted dump truck for operations that require work on sandy, bog, dirt, snow, or muddy terrain, hi-rail dump truck for use in railway projects, and underground dump truck for use in both hard-rock and soft-rock underground mining and tunnel construction projects. The new range is upgraded with a range of features including a new cab, a new self-levelling front suspension and a new tandem bogie system. It also incorporates a new cab and a semi-levelling front suspension that adjusts itself independently depending on the operating conditions to ensure a comfortable working environment for the operator.

Conclusion

Discussed above are different types of hauling equipment above. Based on your project requirements you should select the equipment that fits your requirement.

Image Source: cat.com/en_IN/, tatahitachi.co.in, tilindia.in, deere.com, komatsuindia.in