Structurally, the profile for gypsum board consists of a back, which is needed to attach to a horizontal or vertical surface, and walls, which are responsible for the rigidity and strength of the base. In some cases, a bullnose corner bead may be used to achieve rounded edges, adding both aesthetic appeal and durability. The materials used in the production of these products are metals: aluminum and steel. The correct choice of profiles for plasterboard on the material is determined by the operating conditions. Aluminum products have the best practical characteristics, but their cost is higher than that of steel taxes. If preference is given to steel fasteners, it should be remembered that for rooms with an increased level of humidity (kitchen, bathroom, bathroom) it is rational to buy moisture-resistant copies with a zinc coating that protects against corrosion. In this situation, plasterboard systems will serve for a long time, without the need for premature repair. So, the appearance of corrosion is dangerous in that rust over time can show through the putty and even the finishing. If the room has a normal microclimate, it is acceptable to buy a profile for plasterboard from ordinary non-galvanized steel.

Classification: the main types by shape and purpose

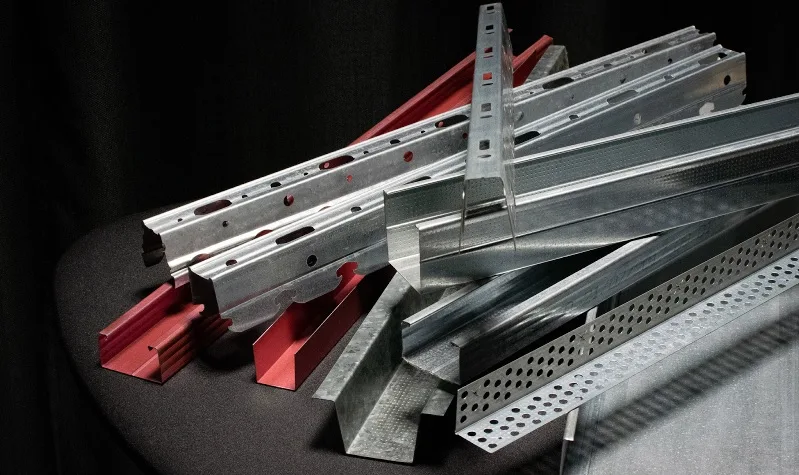

The following types of profiles for plasterboard systems are available:

- Guiding (UW). The is U-shaped, the surface is smooth. This type is needed to create frame supports, posts, and lintels. It is attached at the edges, and then other parts of the system are installed in it.

- Rack (CW). The cross-section also resembles the letter “U”, but there are additional stiffening ribs. Installed in the UW, after which the plasterboard is attached.

- Ceiling. It is represented by two types – ceiling guide (CD) and bearing (UD). Their reduced parameters are due to the fact that the ceiling GPB (gypsum plasterboard) is thinner, and appropriate fasteners are needed. In addition, with this approach, the height of the room is not “taken away”. The function of the guide type is to form shaped ceiling elements inside the finished frame. The load-bearing type is equipped with additional stiffeners and low shelves to withstand loads.

When it is planned to build arched structures, an arch profile will be needed. It is not marked with a specialized marking. For increased flexibility, cuts are provided on the side ribs.

Additional species and accessories

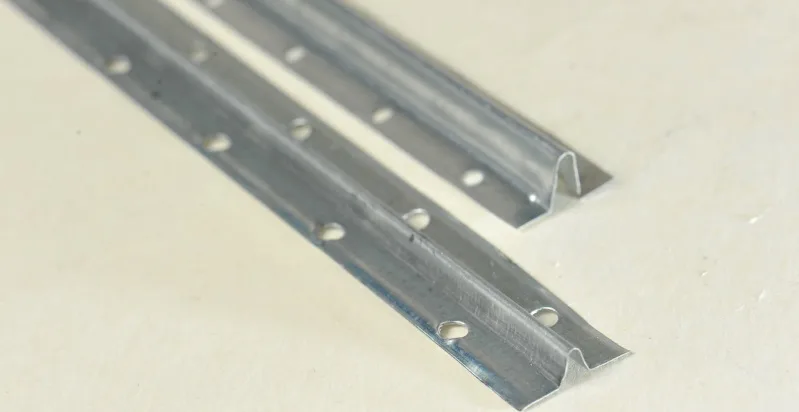

The category of auxiliary parts includes screed profile (screed guide) and gypsum drywall corner (CP). The drywall cornerbead is used to guide the rule during plastering works. Corner modifications are represented by the following subspecies:

- Building materials without perforation – the shelves are solid.

- Perforated products – the shelves have large holes required for fixing on the plaster.

- Mesh corners – equipped with a mesh that provides better adhesion to the surface.

- Paper-backed corners. They look like two metal walls, which are attached by adhesive bonding to dense paper. This type is used for leveling places that are not subject to heavy loads.

Accessories may also be required to create a stable and reliable structure. Their list depends on the specifics of the project. These include extensions, hangers with perforations or anchors, one-level or two-level connectors. Sometimes accessories are replaced by homemade parts, but in order to build partitions or ceiling installation took less time, it is optimal to visit a building materials store and purchase all the necessary components of the system in advance.