Pile driving is a method used to drive piles into the soil, to provide foundation support for buildings and structures. Piles can be fabricated from concrete, timber, or steel. The piles act as a structural member to transfer the load of the structure to a required depth in deep foundations. Driving piles allows a structure to be placed in an area that would otherwise be unsuitable given the subsurface conditions. There are different types of equipment used for pile driving in construction each of the types, the features and applications are discussed below.

Pile driving equipments and their uses

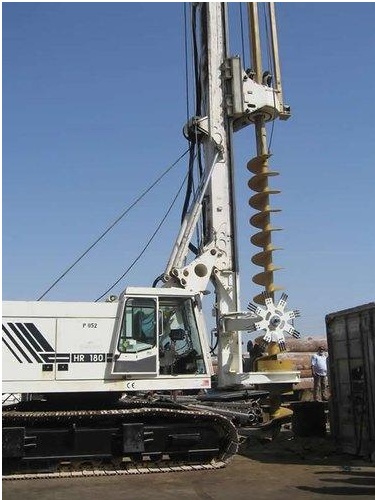

Piling rigs

Piling rigs are mainly used to drill/create piles in soil, clay, etc. It is widely used for cast-in-place piles, diaphragm walls, and foundation reinforcement. It consists of a tabular element or hard box, placed and fixed on a crane base. Piling rigs in India come with different features that can be utilized to dig within the earth’s subsurface, making of the water wells, oil wells or natural gas extraction wells, or to install sub-surface fabrications. It is designed for multipurpose use and can be equipped with special kits for different foundation and geotechnical construction methods including, drilled shafts, caissons, continuous flight auger, diaphragm walls, etc. The features include;

- Integrated with mechanical, electrical and hydraulic systems

- Comes with 360⁰ camera rearview for operator efficiency

- Emergency stopping of machine possible

- Attached with Boom micro-switch for control of the stability limit

- Double-rotary interlocking kelly bars for transfer of torque and crowd force from the rotary drive to the drilling tool

- Interlocking bars with the higher pulling force for the tougher terrain

- Interlocking kelly bars for pulling up during the extraction phase with the main winch and the rotary

- Comes with a parallelogram for precise positioning

Rotary Drilling Rig

Rotary Drilling Rig uses a sharp, rotating drill bit and downward pressure to cut or crush, through the subsurface. Impact energy is supplied to the drill bit from either an above-ground or down-hole impact hammer. This impact force aids in the drilling. They can be used in deeper depths and are capable of larger diameter holes. Its feature include;

- Both the counterweight and the leader are modularly constructed

- The control system comes with program and control options for various drilling methods

- Can be equipped with a shortened leader system which is perfect for construction sites with height limitations

- Kelly bar is made of high strength steel tubes with light design

- Interlocking kelly bar is offer higher torque output and maximum pile depth

- Comes with special drilling attachment for anti-seismic piles

- Tailored chassis with larger spaces for pumps and valves is for easy maintenance

- Equipped with a modern air-conditioning system with improved airflow for operator

- An optimized field of vision and increased noise protection for the operator

Hydraulic impact pile hammer

Hydraulic impact pile hammers are suitable for driving steel tube pipes, sheet piles, precast concrete and timber piles. The stroke and blow rates are adjustable to optimize the pile driving performance in all conditions. The ram weight can also be changed according to pile type requirements. All this means that one hammer serves efficiently a wide range of different pile driving operations. The hammers can be mounted on all kinds of pilling leaders or can be freely suspended. It is suitable to be used as a leader mounted on piling rigs and piling cranes as well as crane suspended. Different features of this machine utilized for Indian terrain includes;

- Adjustable hammer impact stroke

- Smoothly adjustable impact frequency

- Easy to connect to different hydraulic systems

- Modular ram block design

- Drive caps are available for all types and sizes of piles.

- Double-acting hammers provide high work rates

Vibratory pile hammer

A vibratory hammer is used to drive sheet piles, pipes or other elements into the soil by vertical vibrations. The adjacent soil particles are put into motion and thus the soil is ‘loosened’. The dynamic weight of the hammer drives the elements into the soil. Apart from driving and extracting elements such as sheet piles and pipes, vibratory hammers are also used for soil densifying or vertical drainage across multiple projects in India. Its features include;

- Variable frequency, weight and line pull for job matching

- Attached with hammer brake to minimize boom shake

- High efficiency, bent axis, piston motors

- Open-loop hydraulics for efficiency and reliability

- Rotating gears with 360° feature

- Internal clamp comes with check valve from damage protection

- Easy handling and easy adjustment of clamping devices

Conclusion

Each of the equipment types is discussed above but the type of pile driving equipment used often varies according to conditions ranging from soil consistency to depth of piles required. The pile driving equipment market in India is driven by infrastructure projects undertaken by the government and other commercial construction projects. With the advent of rapid industrialization and modernization in operational processes, digital technologies play a crucial role. The companies are more inclined to offer digitally advanced piling equipment suited to the Indian terrain to the customers to gain a competitive edge in the market.