Joints are an important part of all concrete floors and their design and construction require careful attention. The improper use of a right joint will lead to floor failure with continual deterioration. Joints can be a potential source of problems because the edges of slab panels are vulnerable to damage. The damages can be caused by the passage of continual MHE movement, horizontal, vertical and rotational strains and pressures. The result will be cracking and spalling. The number and type of joints in a floor will depend on the floor construction method and its design.

Joint selection will be based on the following characteristics: resistance, configuration, formation and location.

- Resistance: Tied or reinforced, dowelled, non dowelled, plain

- Configuration: Butt, lap, tongue, and groove.

- Formation: Sawed, hand-formed, tooled, grooved, insert form.

- Location: Transverse, longitudinal, vertical, horizontal.

Joints are provided for two reasons, to relieve tensile stresses induced by drying shrinkage or temperature changes and to cater for breaks in the construction process. The types chosen should be related to the planned use of the floor and other factors.

Floor Joint Types

Floor joints are classified according to the movement they allow and the method by which they are formed, as follows:

- Free-movement joint

- sawn

- formed

- Restrained-movement joint

- sawn

- Formed

- Tied joints

- Isolation joints

FREE-MOVEMENT JOINTS

Free-movement joints are designed to provide a minimum of restraint to horizontal movements caused by drying shrinkage and temperature changes in the floor while restricting relative vertical movement.

- There is no reinforcement across the joint.

- Free movement and load transfer are both achieved by the installation of dowels.

- Free-movement joints which are going to be heavily trafficked should be of an armoured type to minimise damage to the joint.

- These joints are usually provided between pours.

Sawn free-movement joints

Sawn free-movement joints are cut as soon as the concrete is strong enough to be cut without damaging the arrises.

- Debonded dowels set in position in dowel cages before the concrete is placed provide load transfer.

- The dowels must be horizontal and perpendicular to the line of the joint and that their positions are not disturbed during the placing of the concrete.

Formed free-movement joints

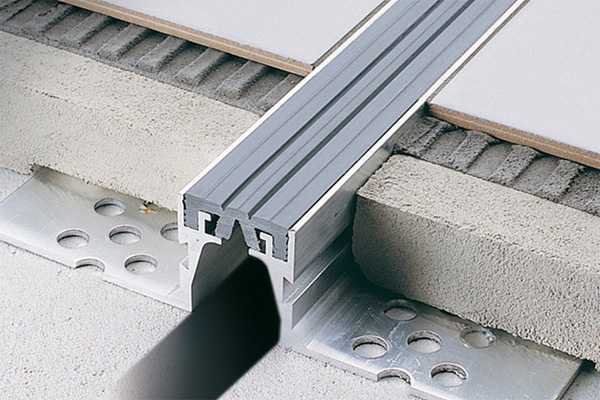

Formed free-movement joints are created by formwork and are provided at the perimeter of each bay and use debonded dowels or discrete plate dowel systems to provide load transfer. Formed joints mark the boundaries between separate pours of concrete. Debonded dowels, plate dowel systems, or steel tongue-and-groove systems provide load transfer.

- Dowels can be round, square or plate types.

- Round bars allow longitudinal movement only.

- The sleeves of square dowels have compressible side inserts to allow lateral as well as longitudinal movement.

- Sleeves should be of a shape compatible with the dowel and with a good fit and sufficient stiffness to prevent vertical movement.

- The edges are protected with steel plates of adequate thickness to provide sufficient stiffness and resistance to bending from MHE impact.

RESTRAINED-MOVEMENT JOINTS

Restrained-movement joints are provided in fabric reinforced floors to allow limited movement to relieve shrinkage-induced stresses at predetermined positions. The fabric reinforcement is continuous across the joint.

Sawn restrained-movement joints

Sawn restrained-movement joints are sawn as soon as the concrete is strong enough to be cut without damaging the arrises.

- They are made by cutting the slab at predetermined points to induce cracks which divide the slab into panels relieving the shrinkage stresses in the slab.

- These cuts should be made within 24 hours of casting to ensure that the shrinkage stresses have not already exceeded the tensile capacity of the concrete.

- Load transfer is provided by the doweling action of the reinforcement and aggregate interlock.

Formed restrained-movement joints

Formed restrained-movement joints are created by using formwork through which reinforcing bars are inserted.

- The joint is designed for some limited horizontal movement,

- The bar dimensions and spacing give approximately equivalent cross-section per metre length of joint to that of the fabric in the slab.

- Deformed bars are set in the concrete across the joint to provide load transfer between the two slab sections, as the fabric reinforcement does not continue through the joint.

TIED JOINTS

Tied joints are provided to facilitate a break in construction at a point other than at a free-movement joint. The joint is provided with a cross-sectional area of steel reinforcement high enough to prevent the joint opening.

ISOLATION JOINTS

Isolation joints are used to avoid any restraint to the slab by fixed elements at the edges of or within the floor. This joint completely isolates one slab from another structural member, such as a column, wall or pipe.

- Isolation joints are created by placing the preformed joint material in the desired location before the concrete slab is poured.

- The slab is then cast with the isolation joint material acting as formwork between the slabs, though unlike formwork, the joint material remains permanently within the slab.

- When the concrete has cured enough so that it will retain its shape, the top cap of the preformed joint material can be removed and the gap filled with sealant.

* In special conditions there is a definite need for expansion joints. They are not used in internal floors, except those subject to above-ambient temperatures and to large temperature fluctuations.

Conclusion

The detailing of joints is an important aspect of floor design and this is provided by experienced experts only. Well-designed and constructed joints will enhance both a flooring appearance and give the desired performance. It is advisable to take expert opinion as designing for effective crack control requires an understanding of the sources of stress which may cause cracking. In an upcoming series of articles we will cover armouring of joints, Installation of joints and different types of joint layout objectives.

Analysing the concept of Floor Joints;