PRONIL PROSEAL is a high-performance thermoplastic elastomer (TPE) tape specifically designed for sealing and waterproofing joints and cracks. This extra-tough, elastic strip is perfect for expansion joints and cracks that experience irregular and significant movement. Its exceptional flexibility provides a reliable, watertight seal, even in areas subjected to high stress and shifting. The tape’s longitudinal and lateral expansion capabilities allow it to accommodate shifts and stresses in the substrate, ensuring a durable and secure seal in high-movement areas.

Engineered to withstand harsh environmental conditions, the sealing tape offers excellent resistance to weathering, UV radiation, and chemicals. Its chemically stable composition ensures long-lasting performance, even under exposure to sunlight or aggressive substances. This exceptional resilience makes it the perfect choice for use in demanding environments, ensuring reliable performance even under the most challenging conditions.

Advantages of PRONIL PROSEAL

- Flexible & permanently elastic

- Highly versatile

- Good tensile properties

- Stable form and UV-resistant

- Heat weldable

- Easy to install

- Long term resistance to bacterizes

- Non-hazardous for users

Standard Sizes Available:

- Width: 150 mm

Thickness Options: 1 mm, 1.25 mm, 1.50 mm, 2 mm

Length: 25 meters - Width: 200 mm

Thickness Options: 1 mm, 1.25 mm, 1.50 mm, 2 mm

Length: 25 meters - Width: 250 mm

Thickness Options: 1 mm, 1.25 mm, 1.50 mm, 2 mm

Length: 25 meters - Width: 300 mm

Thickness Options: 1 mm, 1.25 mm, 1.50 mm, 2 mm

Length: 25 meters - Width: 350 mm

Thickness Options: 1 mm, 1.50 mm

Length: 25 meters - Width: 400 mm

Thickness Options: 1 mm, 1.50 mm

Length: 25 meters

Uses of PRONIL PROSEAL

- Sealing construction joints and cracks to prevent water ingress

- Waterproofing and sealing in basements, ensuring long-term protection

- Sealing in tunnel construction, providing reliable waterproofing under pressure

- Protecting metal surfaces from corrosion by creating secure, durable seals

- Waterproofing for swimming pools, ensuring leak-free structures

- Sealing cable and pipe penetrations to prevent water or chemical infiltration

- Waterproofing and sealing in sewage treatment plants for lasting protection

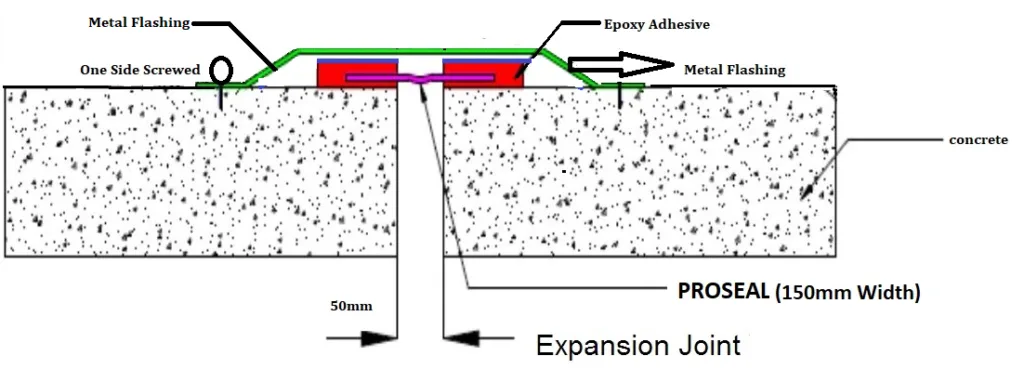

Application Methodology of PROSEAL – Expansion Joint Tape (Horizontal Area)

Surface Preparation:

- Surfaces must be clean, sound, and dry.

- Repair broken edges with high-strength readymade mortars.

- Ensure joints are straight.

- Remove dust, oil, grease, and other contaminants from the surface.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Combine the “B” component with the “A” component and mix until the mixture is uniform in color.

- Use a low-speed mechanical mixing device and a suitable mixing paddle.

Application:

- Apply EPOXY ADHESIVE on both sides of the joint, ensuring both sides of the PROSEAL tape are embedded over a width of at least 40mm.

- Maintain a layer thickness of approximately 2mm for the EPOXY ADHESIVE.

- Immediately embed the PROSEAL tape into the fresh EPOXY ADHESIVE, pressing it with a hand roller or similar tool to ensure good contact.

- Apply a second layer of EPOXY ADHESIVE over the PROSEAL tape, covering the edges by at least 40mm.

- Apply EPOXY ADHESIVE at a width of at least 20mm on the substrate next to the PROSEAL tape.

Protection During Screed:

- Lay a 200-250 GSM geotextile membrane or a board over the TPE tape to protect it during the screed.

- Maintain an open gap during screeding for the expansion and contraction of the joint and tape.

Foot Traffic and Driveway Protection:

- For normal foot traffic, install a 1.25mm GI or aluminum plate fixed with one-sided screws.

- For driveways, use a top layer of aluminum or GI chequered plate (minimum thickness of 5mm) to protect the system, secured with one-sided screws.

Application Methodology of PROSEAL – Expansion Joint Tape (Vertical Area)

Surface Preparation:

- Ensure surfaces are clean, sound, and dry.

- Repair broken edges with high-strength readymade mortars and ensure joints are straight.

- Remove dust, oil, grease, and other contaminants from the surface.

Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Combine the “B” component with the “A” component and mix until the mixture is uniform in color.

- Use a low-speed mechanical mixing device and a suitable mixing paddle.

Application:

- Apply EPOXY ADHESIVE on both sides of the joint, ensuring both sides of the PROSEAL tape are embedded over a width of at least 40mm.

- Maintain a layer thickness of approximately 2mm for the EPOXY ADHESIVE.

- Immediately press the PROSEAL tape into the fresh EPOXY ADHESIVE using a hand roller or suitable tool to ensure good contact.

- Apply a second layer of EPOXY ADHESIVE over the PROSEAL tape, covering the edges by at least 40mm.

- Apply EPOXY ADHESIVE over the substrate next to the PROSEAL tape with a width of at least 20mm.

Protection for Vertical Surfaces:

- For vertical applications, install a 1.2mm GI or aluminum plate from the ground level to 7 feet above the finished floor level, fixed with screws on both sides.

Painting (For Vertical Surfaces):

- PROSEAL Expansion Joint Tape can be painted with any acrylic or hybrid UV-resistant coating systems.

Application method reference- https://constrofacilitator.com/proseal-expansion-joint-tape-advantages-and-applications/

PRONIL PROSEAL Expansion Joint Tape offers a reliable, flexible sealing solution for demanding applications. Its durability and resistance to environmental factors ensure long-term waterproofing in construction joints, tunnels, and more, making it ideal for both horizontal and vertical installations.

About PRONIL Construction Chemicals

Pronil manufactures a wide range of Expansion Joint tapes and Waterproofing flexible Joint sealing tapes. The company also manufactures high-performance Acrylic Swellable Bars and Bentonite Hydrophilic Waterstops. The company provides waterproofing solutions for everything from foundations to construction joints, with a wide range of tapes to meet any project needs.

About the author

The author is the Business Head for PRONIL, overseeing operations in India and South-East Asia. With more then two decades of experience, he plays a an important role in managing and leading the company’s business division. His responsibilities includes strategy development, sales, marketing, product development, and customer relations.

Pronil India

Alaka Palazzo, No.4/219, Flat No.B-1101, Block- II, Poonamallee High Road, Kattupakkam, Chennai- 600056 India

Mobile: +91 94890 58644

Email id: maruthu@pronil.com

Website: www.pronil.com