The structural system of a high-rise building is designed to cope with vertical gravity loads as well as lateral loads caused by wind or seismic activity. The structural system consists only of the members designed to carry the loads, and all other members are referred to as non-structural. The determination of the structural system for a high-rise building involves the selection and arrangement of the major structural elements to resist most efficiently the various combinations of gravity and lateral loading. A high-rise building needs to be stabilised for horizontal load and to achieve this, several different structural systems can be chosen. All of the different systems have evolved from the traditional rigidly jointed structural frame. The fundamental design for all these structural systems has been to place as much of the load-carrying material as possible around the building’s external fringe to maximise its flexural rigidity.

Different types of Structural Systems in High-Rise buildings

Braced frame structural system

A braced frame is used in structures subject to lateral loads such as wind and seismic pressure. The members in a braced frame are generally made of structural steel, which can work effectively both in tension and compression. The beams and columns that form the frame carry vertical loads, and the bracing system carries the lateral loads. The positioning of braces, however, can be problematic as they can interfere with the design of the façade and the position of openings. Buildings adopting high-tech or post-modernist styles have responded to this by expressing bracing as an internal or external design feature. In braced frames, the beams and columns are generally arranged in an orthogonal pattern in both, the elevation and on the plan. The structural members are joined using a pinned connection which does not transfer moments. This structured system is designed to withstand wind and earthquake forces. Members in a braced frame are not allowed to sway laterally. Due to bracing, lateral story displacement, story drift, axial force and bending moment in columns are greatly reduced.

Rigid frame structural system

A rigid frame structural system is the load-resisting skeleton constructed with straight or curved members interconnected by mostly rigid connections, which resist movements induced at the joints of members. Its members can take a bending moment, shear, and axial loads. The two common assumptions as to the behavior of a building frame are that its beams are free to rotate at their connections or that its members are so connected that the angles they make with each other do not change under load. Frameworks with connections of intermediate stiffness will be intermediate between these two extremes. Frameworks with connections of intermediate stiffness are commonly called semi-rigid frames. In this type of structural system beams and columns are constructed monolithically to withstand moments imposed due to loads and withstands bending moment, shear force, and axial loads.

Concrete dual structural system

A dual system is a structural system in which an essentially complete frame provides support for gravity loads, and resistance to lateral loads is provided by a specially detailed moment-resisting frame and shear walls or braced frames. Both shear walls and frames participate in resisting the lateral loads resulting from earthquakes or wind or storms, and the portion of the forces resisted by each one depends on its rigidity, modulus of elasticity and its ductility, and the possibility to develop plastic hinges in its parts. The moment-resisting frame may be either steel or concrete, but concrete intermediate frames cannot be used in seismic zones. In the dual system, both frames and shear walls contribute to resisting the lateral loads. This type of structural system comprises of a group of beams and columns connected by rigid joints, and the frames bend following shear mode, whereas the deflection of the shear walls is by a bending mode like the cantilever walls.

Shear wall structural system

A shear wall is a structural member used to resist lateral forces i.e. parallel to the plane of the wall. For slender walls where the bending deformation is more, the Shear wall resists the loads due to Cantilever Action. A shear wall is stiffer in its principal axis than it is in the other axis. It is considered a primary structure that provides relatively stiff resistance to vertical and horizontal forces acting in its plane. Under this combined loading condition, a shear wall develops compatible axial, shear, torsional and flexural strains, resulting in complicated internal stress distribution. In this way, loads are transferred vertically to the building’s foundation. Shear walls withstand both gravity and lateral loads, and it acts as a narrow deep cantilever beam. Shear walls are particularly important in large, or high-rise buildings, or buildings in areas of high wind and seismic activity. It can be positioned at the perimeter of buildings or it may form a shear core – a structure of shear walls in the centre of a high-rise building.

Outrigger structural system

Outriggers are interior lateral structural systems provided to improve the overturning stiffness and strength of high-rise buildings. It is a lateral load resisting system that is located within the building. The whole system consists of a core structure connected to the perimeter columns of the building using structural members called outriggers. The outriggers can be in the form of horizontal beams, truss, or walls. Outrigger systems can be made of any material of concrete, steel, or composite. With these structural systems, uplift and tension forces can be reduced significantly throughout the columns and foundations. The spacing of the outside columns can be driven by architectural and functional considerations, not structural considerations. The structural system reduces the overturning moments and provides greater efficiency in resisting forces. Outrigger engages the perimeter columns in lateral load resisting action which would otherwise act as a gravity load resisting elements

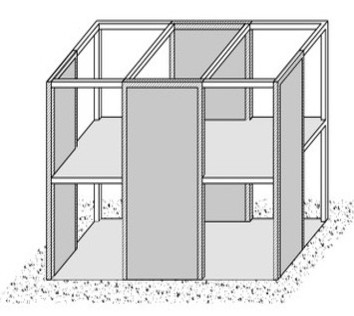

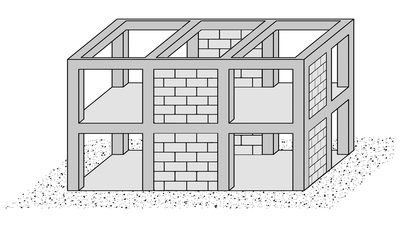

Infilled frame structural system

In the infilled frame structural system beams and columns in which some bays of frames are infilled with masonry walls that may or may not be mechanically connected to the frame. Due to great stiffness and strength in their planes, infill walls do not allow the beams and columns to bend under horizontal loading, changing the structural performance of the frame. During an earthquake, diagonal compression struts form in the infills so the structure behaves more like a Braced Frame rather than a Moment Frame. Infill walls can be part-height or fill the frame. When an infilled frame is subjected to in-plane loading, the frame members and the infills interact to develop a combined resistance to the load, the members deforming mainly by bending and axial stresses and the infills by in-plane shear and direct stresses.

Tube structural system

The tube is a system where, to resist lateral loads (wind, seismic, impact), a building is designed to act like a hollow cylinder, cantilevered perpendicular to the ground. The tube system can be constructed using concrete, steel or a composite of both. In its simplest form, closely-spaced columns are tied together with deep spandrel beams through moment connections as part of the external perimeter of the building. The rigid frame that this assembly of columns and beams forms results in a dense and strong structural ‘tube’ around the exterior. Since lateral loads can be resisted by this stiff exterior framing, interior columns can be located at the core and are fewer in number. The interior can be simply framed for gravity loads and floor space is left free from columns. This type of structural system consists of a Framed tube, a Trussed tube, Tube-in-tube, Bundled tube and a Hybrid system.

Flat plate and flat slab structural system

Flat plate and flat slab structural systems are two-way reinforced concrete slab that usually does not have beams and girders, and the loads are transferred directly to the supporting concrete columns. It’s a couple-way system normally bolstered legitimately on columns or burden-bearing dividers. It is one of the most widely recognized types of construction of floors in structures. In this type of structural system lateral resistance depends on the flexural stiffness of the components and their connections.

Coupled wall system

Coupled walls are lateral load resisting systems that not only reduce the deformation demands on the building but also distribute inelastic deformation both vertically and in the plan, between the coupling beams and the wall piers. When subjected to large seismic loads, coupling beams may deteriorate relatively quickly exhibiting both strength and stiffness degradation. This structural system is composed of two or more interconnected shear walls and are connected at the floor levels by beam or stiff slabs.

Hybrid structural system

A hybrid structural system is composed of two or more of basic structural forms either by direct combination or by adopting different forms in different parts of the structure. It has a notable advantage in decreasing self-weight, reducing the section size of structural members, and accelerating construction progress.

Conclusion

Discussed above are different types of structural systems used in high-rise buildings. The right analysis must be done by experts to choose the type of structural system that caters to the requirement of high-rise buildings.