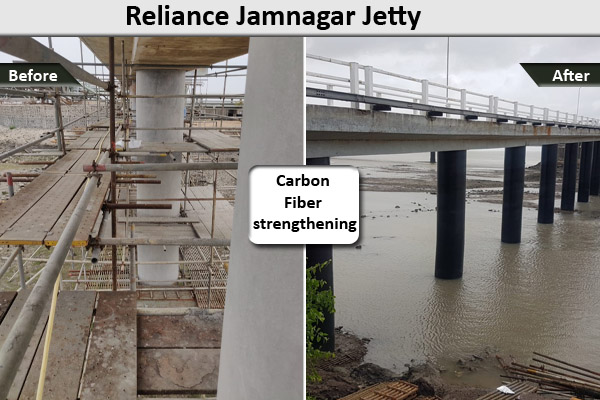

The load-bearing capacity deteriorates in the jetties due to higher than anticipated live loads, changes to the structural condition, corrosion or defects in the original design of construction. This can lead to insufficient longitudinal or transverse bearing capacity of the jetty which leads to cracks. In such scenarios appropriate retrofitting method and material is a prerequisite to regaining its structural strength. One such case study is being discussed wherein the CFRP reinforcement method was used to restore the structural strength of the jetty.

The project in focus is Reliance Jamnagar Jetty located on the western coast of India in the state of Gujarat in the Saurashtra region. The jetty was retrofitted using Carbon fiber and composites- RELinforce™ solutions including underwater curing Epoxy solution for water submerged portions. It was applied to existing composite materials for reinforcement and corrosion resistance. RELinforce™ comes with properties such as high tensile strength, high stiffness, high strength to weight ratio, high chemical resistance, temperature tolerance to excessive heat and low thermal expansion. It is applied in the form of a flexible fabric during installation, then saturated with a resin matrix, allowing it to harden to transform to a strong, unyielding material with a strength-to-weight ratio.

We have focused on the site requirement, retrofitting method and material used in the project. This contains a brief detailing of the measures undertaken in 2019 and 2020 project site visit was done to prepare a report on monitor whether to meet structural strengthening criterion was met.

Jamnagar Jetty Site Report- March 15, 2019

Site Requirements: Reliance Jamnagar Jetty piles were under continuous immersion in seawater which was affecting the load-bearing capacity of the bridge. Due to such a harsh environment, the strength of the piles was deteriorating day by day. To address this problem and keep the jetty and Jamnagar port working we retrofitted the jetty piles using the Carbon Fiber strengthening solution.

Solution Provided: 18-19 piles of the jetty bridge were retrofitted using Carbon fiber and composites solutions including underwater curing Epoxy solution for water submerged portions.

Timeline for Completion of Work: 3-5 Months (Including Surface Preparation to Final Wrapping process)

Materials Used:

- RELinforce™ C Fab 600

- RELinforce™ Fab S PR (Primer)

- RELinforce™ Bondcoat Putty

- RELinforce™ Fab S

- RELinforce™ Fab S UW (Under-Water)

Site Background & CFRP Application:

- Retrofitting the pile section which is underwater or submerged during the high tide timing was the biggest problem during executing the work. So each pile was divided in two sections. The first section was the lower portion of the pile which is underwater or submerged during the high tide while the other section was the dry section as it remains dry all time of the day.

- Monitoring was done for the high tide and low tide timing while working and calculated the working hours for the lower section of the pile. The retrofitting of the lower section of the piles was done during the low tide hours and the remaining time was utilized to do work on the dry section.

- Surface preparation and micro-concreting work were done for each and every pile before starting the carbon fiber wrapping process.

- These surface- prepared piles were then primed using the RELinforce™ Fab S PR primer. The same primer was used for both sections as the primer was moisture insensitive.

- Once the primer becomes tacky, putty RELinforce™ Bondcoat Putty was applied to the required surface to make the surface smooth for fiber application.

- The putty layer was left to dry properly for 6-7 hours.

- The carbon fiber wrapping process was done using two different saturants. The lower underwater pile section was carbon wrapped using the RELinforce™ Fab S UW (Under-Water) saturant during the low tide timing and let it cure for 24 hours.

- The dry section of the piles was then carbon wrapped using the RELinforce™ Fab S, similar curing cycle of 24 hours was used.

Jamnagar Jetty Site Report- March 15, 2020

In 2020 a detailed site background & CFRP application performance checking was done to observe the performance of the jetty after Carbon Fiber Strengthening. Here are the observations;

- The bearing capacity of structural components (bending, shear) were improved

- Enhancement of ductility and flexibility of the jetty was done

- The structure was not impacted due to the corrosive environment

- After curing, CFRP formed new stress which worked together with the original component, thus playing a strengthening role

- After the CRPF installation, the weight of the original structure and the size of the original components had not increased

Final Assumption- All the criteria of structural strengthening were met for Reliance Jamnagar Jetty.

About Relinforce™ Carbon wrap & Glass Fiber-reinforced polymer products

Relinforce™ range of Carbon wrap & Glass Fiber-reinforced polymer products are manufactured and supplied under Reliance India’s Composites Solution Division. Reliance Industries Limited is India’s largest private and one of the most profitable private sector companies and the first Indian Fortune 500 company.

Relinforce™ product range is used for structural strengthening & protection of the structural members using guidelines that conform to international standards. These products just don’t repair degraded structures, but it makes the structures stronger even against harmful effects of seismic forces or further corrosion. There is a wide range of products combined with outstanding combinations of properties, such as low weight, immunity to corrosion, excellent mechanical strength and stiffness to tackle the issues on hand with ease. To know more about the product, visit- https://www.reliancecomposites.com/