Repair and retrofitting of vulnerable bridges is a necessity in the city of Kolkata. The bridges in the city of Kolkata are as old as its culture and heritage, one such bridge is the Chitpore bridge. As per getbengal.com in 1843, it was constructed under the engineering leadership of Captain John Thomson, who was the Superintendent of Canals and Agent for Iron Suspension Bridges. It spans 99 feet and has a roadway that is 24 metres wide. It was popularly referred to as the Bagbazar Bridge.

It is one of the earliest examples of the bowstring bridge. Deterioration is a common problem in bridges and Chitpore Bridge is no exception.

KMDA conducted structural inspection of Chitpore bridge

The Kolkata Metropolitan Development Authority KMDA, conducted structural inspection of several bridges in Kolkata and came to a realisation that Chitpore bridge falls under the category of “vulnerable bridges and flyovers”. It needed immediate repair and restoration to avert any major mishap in the near future.

Non- Destructive Test of Chitpore Bridge

In August 2019, ️LASA was awarded consultancy services for Chitpore Bridge. The present condition of the bridge was soon surveyed and Non- Destructive tests were performed. The seemingly healthy bridge revealed active corrosion in selected areas. NDT test revealed that;

- In the vertical hangers, steel reinforcement has lost its diameter at several locations

- Spalled portions and discontinuous rebars were visible in hanger columns, under the deck slab and on cross beams

- The structural strength of sectional members was compromised by corrosion

- Pitting corrosion of the embedded steel in the vertical hangers and in the beams supporting the deck

Adding to its already distressed condition, nearby Tala Bridge was closed down, sending substantial traffic to Chitpore Bridge. To prevent a catastrophe, an immediate strengthening of the structural system was necessary. It had to be done fast with due diligence. That’s where Sanrachana came to the rescue.

Repair and Retrofitting of Chitpore Bridge executed by Sanrachana

Sanrachana is one of the pioneers in the area of structural retrofitting & protection in India and has decades of experience in executing bridge repairs across the country. It has served clients on over 2000 projects involving commercial properties, industrial facilities, energy plants and public infrastructure of varying scale.

Overview of work executed:

- Sandblasting, anti-corrosion treatment

- Providing additional rebars, micro-concreting

- Strengthening of hangers, deck & cross beams with SRM carbon laminates & SRM C-wraps

- Post-tensioning 4 Mac-alloy bars with 5 tons each, to counteract tension on each hanger

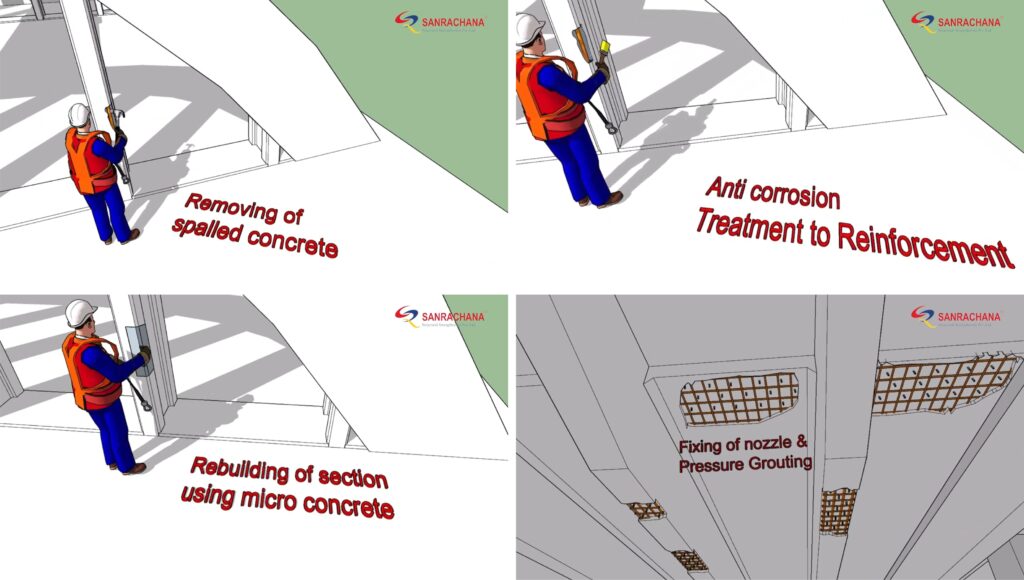

The team started repair work with sandblasting in Chitpore to get clarity on underlying distressed concrete. Delamination and spalling were detected and removed with a hammer and chisel. The exposed rebars of the hangers were treated for corrosion. The section was rebuilt with high-strength micro concrete.

The underside of the bridge was made accessible with platforms supported by a structural steel section.

With basic repairs done, the team moved towards strengthening.

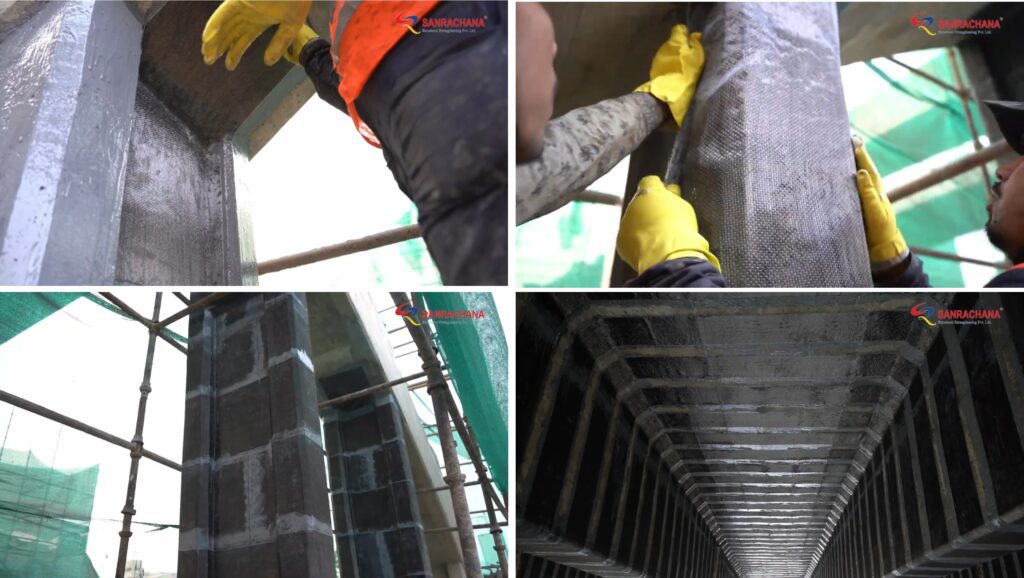

The strengthening of hangers, decks & cross beams was done with SRM C-Lam carbon laminates & SRM C-wraps.

The base of the hangers were armoured with a 1.2m cover block. Structural steel sections were used on the top of hangers above the RCC arch. Connecting these, high-strength Mc-alloy threaded bars were installed. The tensioning mechanism was to be operated from the top of the hangers.

Mechanism of post-tensioning

Upon tightening the McAlloy bars, tension force is developed in it, because of which, a reaction force of compression is generated on the RCC hangers. With the application of protective coating, the work was completed. All the contract criteria were met by Sanrachana.

ABOUT SANRACHANA STRUCTURAL STRENGTHENING PVT. LTD.

The company is committed to taking responsibility of the structural retrofitting projects right from planning and design to execution giving due consideration to budgets, schedules, service life or any other unique structural requirement and completing the projects in a safe, planned and professional manner. They are a leading service provider in the field Structural Repairs, Rehabilitation, Strengthening & Retrofitting.

For more details, visit- https://sanrachana.in/