What is an Interlocking Block Making Machine?

Interlocking block making machines are used to produce blocks with a unique interlocking design used for diverse construction and infrastructure projects. The machine facilitates the efficient production of interlocking blocks by combining raw materials like soil and cement, which are then compressed and shaped within a molding unit. These machines come in various configurations, from manual to semi-automatic or fully automated. Additionally, they come equipped with various molds to create a range of interlocking block styles and sizes, catering to the specific needs of various projects.

How is it different from other block making machines?

What sets interlocking block making machines apart from other block-making counterparts is their distinctive design approach. Unlike conventional machines, they adopt a dry stacking construction method, allowing blocks to be assembled without the need for mortar or adhesives. This not only results in a faster construction process but also eliminates the common use of mortar seen in traditional block making.

Applications of interlocking block making machines

- Residential and Commercial Buildings

- Road Construction

- Landscaping Projects

- Public Infrastructure

- Retaining Walls

- Pavements and Walkways

- Affordable Housing Projects

- Customizable Building Elements

Components of interlocking block making machines

Interlocking block making machines typically consist of several key components:

- Mixer: Responsible for blending raw materials like cement, sand, and aggregate to create the mixture used for block production.

- Feeder: Facilitates the controlled input of the mixed material into the machine, ensuring consistent block quality.

- Hydraulic System: Essential for providing the necessary pressure to mold and compact the interlocking blocks.

- Molding Section: Shapes the mixture into interlocking blocks according to the desired specifications. It may include molds or a press mechanism.

- Vibration Mechanism: Vibration is applied to the molded blocks to eliminate air gaps, enhance compaction, and improve the overall structural integrity of the blocks.

- Control Panel: Allows operators to manage and monitor the machine’s functions, adjusting parameters as needed for different block designs or material compositions.

- Pallets or Trays: Platforms where the freshly molded blocks are placed for curing and drying.

Different types of interlocking block making machines

Different types of interlocking block making are available based on configuration and types of material used. Each of them are explained below.

Based on configuration

1. Manual Interlocking Block Making Machine

Manual interlocking block making machines are operated by hand, requiring physical effort for the entire block production process. These machines are particularly suitable for smaller-scale projects and areas with limited access to electricity. The manual operation involves filling the mold with the block-making mixture, compacting it through manual effort, and extracting the formed block. Despite having a lower output capacity compared to automated counterparts, these machines are cost-effective, simple to operate, and well-suited for community-based projects where hands-on involvement is essential.

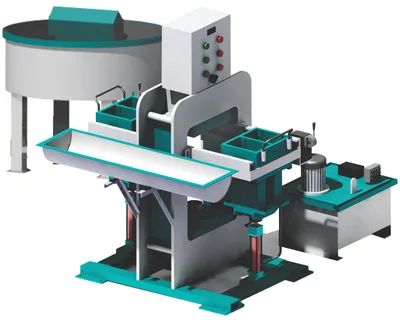

2. Semi-Automatic Interlocking Block Making Machine

Semi-automatic interlocking block making machines strike a balance between manual operation and automated processes, enhancing efficiency. Operators manually load raw materials into the machine, while automated features such as vibrating systems and hydraulic pressure expedite the block production process. This type of machine is ideal for mid-sized construction projects, providing a faster and more consistent production compared to purely manual methods.

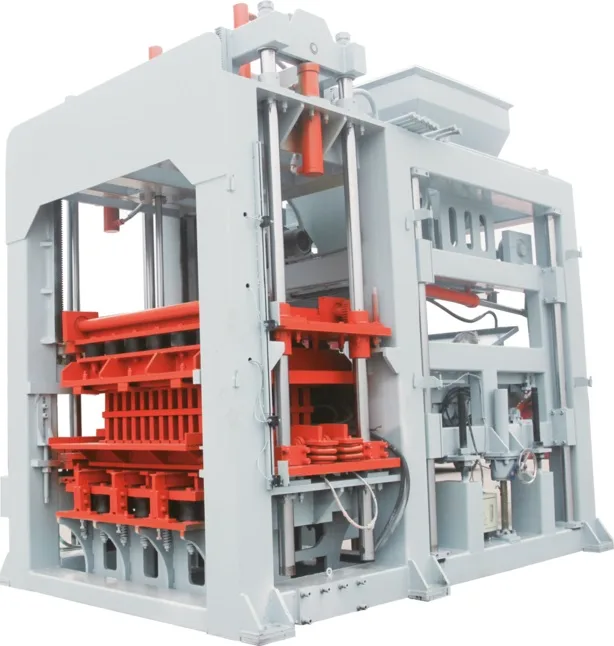

3. Fully Automatic Interlocking Block Making Machine

Fully automatic interlocking block making machines represent the pinnacle of automation in this field. These machines operate with minimal manual intervention, automating the entire block production process. With a higher output capacity, they are well-suited for larger-scale construction projects where efficiency is crucial. From loading the materials to ejecting the finished blocks, the entire process is automated, ensuring consistent and high-quality output with minimal labor requirements.

4. Hydraulic Interlocking Block Making Machine

Hydraulic interlocking block making machines leverage hydraulic pressure to compact the block-making mixture within the mold. This method provides precise control over the compaction process, resulting in uniformly well-compacted blocks. The hydraulic system also contributes to the durability of the blocks by applying consistent pressure throughout the production process. Renowned for their reliability, these machines are capable of producing high-quality interlocking blocks with minimal variation.

Based on materials used

5. Cement Interlocking Block Making Machine

Specifically designed for producing interlocking blocks using a mixture of cement, soil, and water, cement interlocking block making machines are commonly employed where cement is readily available. The process involves carefully mixing the materials, filling the mold, and applying pressure to form interlocking blocks. The use of cement enhances the strength and durability of the blocks, making them well-suited for various construction applications.

6. Fly Ash Interlocking Block Making Machine

Fly ash interlocking block making machines adopt an environmentally friendly approach by incorporating fly ash, a byproduct of coal combustion, into the block-making mixture. This sustainable construction practice utilizes waste material while contributing to the overall strength and durability of the blocks. The process involves mixing fly ash with other materials, molding the mixture into blocks, and applying pressure for compaction, resulting in interlocking blocks suitable for a wide range of construction projects.

7. Interlocking Paver Block Machine

Interlocking paver block machines are specialized for the production of interlocking paver blocks used in driveways, walkways, and landscaping. The process involves using a specific mold design to create blocks with interlocking features, facilitating easy and precise assembly. These machines often offer a range of designs and color options, enhancing the aesthetic appeal of the paved surfaces. The resulting interlocking pavers are durable, resistant to wear, and provide a visually appealing solution for hardscaping projects.

8. Concrete Interlocking Block Making Machine

Concrete interlocking block making machines utilize a concrete mixture for block production, providing strength and durability. The process involves mixing concrete with other additives, filling the mold, and applying pressure for compaction. The resulting interlocking blocks are robust and suitable for various construction applications. These machines are versatile and can produce blocks with different shapes and sizes, catering to diverse project requirements.

Different types of products manufactured with interlocking block making machine

- Interlocking Pavers

- Building Blocks

- Retaining Wall Blocks

- Curbstones

- Garden Edging Blocks

- Permeable Pavers

- Hollow Blocks

- Roadway Interlocking Blocks

- Decorative Wall Blocks

- Bricks:

- Customised Architectural Products

Demand of interlocking block making machines in India

The demand for interlocking block making machines in India has been steadily increasing. Several factors contribute to this demand:

- The Indian government’s focus on affordable housing projects has spurred demand for efficient and cost-effective construction methods. Interlocking block making machines align well with these initiatives, offering speed and affordability in building homes.

- The versatility of interlocking blocks makes them suitable for both rural and urban construction projects. In rural areas, these machines are used for local housing construction, while in urban regions, they contribute to faster infrastructure development.

- The growing awareness of sustainable construction practices has led to increased interest in interlocking block making machines. These machines allow for the use of locally available materials, reducing the environmental impact associated with traditional construction.

- India’s ongoing infrastructure development projects, including road construction, landscaping, and public infrastructure, create a demand for interlocking blocks and, consequently, the machines that produce them.

- The relatively simple operation of interlocking block making machines makes them accessible to a wide range of construction professionals, contributing to their popularity in the Indian market.

Conclusion

Interlocking block making machines offer a sustainable and efficient solution for construction projects. Their ability to produce sturdy, environmentally friendly blocks, coupled with ease of use, contributes to cost-effectiveness and reduced construction time. As the demand for eco-friendly construction methods grows, these machines prove to be a valuable asset, for the way we aim to build for a more sustainable future.

Image Source: bessconcreteblockmachine.com, brickwell.in, qgreentech.com, apolloinffratechblog.apolloinffratech.com, aimixgroup.com, ahpmachines.com, chiragint.com, everonimpex.com, cb-enterprises.co.in