Selecting the right materials for roofing fasteners is paramount for the long-term durability, and safety of a roof. The chosen materials must offer corrosion resistance to withstand environmental elements, compatibility with the roofing material to prevent structural weakening, sufficient holding power to secure the roof, and reduced maintenance needs, ultimately contributing to cost savings. Proper material selection ensures the roof’s ability to protect the structure beneath and maintain its aesthetics.

Different types of roof fasteners materials

Galvanized Steel Roofing Fasteners

Roofing fasteners made of galvanized steel are created by coating carbon steel with a layer of zinc, forming a protective barrier against corrosion. This zinc coating is especially effective in preventing rust and deterioration, making these fasteners well-suited for outdoor applications. Their inherent durability, affordability, and wide-ranging compatibility with different roofing materials, including asphalt shingles, wood shingles, and various metal roofing systems, make them a versatile choice. These fasteners offer a practical solution that can withstand exposure to the elements and are often preferred in roofing projects where cost-effectiveness is a priority.

Stainless Steel Roofing Fasteners

Stainless steel roofing fasteners are renowned for their exceptional resistance to both corrosion and rust. The presence of chromium in stainless steel creates a passive oxide layer on its surface, providing long-lasting protection against environmental factors. These fasteners are a top choice for regions with high humidity, coastal areas, or places exposed to saltwater, where resistance to corrosion is paramount. Their robustness and longevity are particularly valuable for securing metal roofing panels, providing a reliable solution that can endure the test of time.

Aluminium Roofing Fasteners

Roofing fasteners made from aluminium are highly regarded for their lightweight properties and resistance to corrosion. When used in conjunction with aluminium roofing materials, they ensure compatibility that enhances structural integrity. Their lightness is especially advantageous in scenarios where reducing the overall weight of the roof is essential, whether to preserve the structural load-bearing capacity or for lightweight roofing systems. These fasteners offer a reliable and non-corrosive solution suitable for a variety of applications, particularly when weight considerations are a priority.

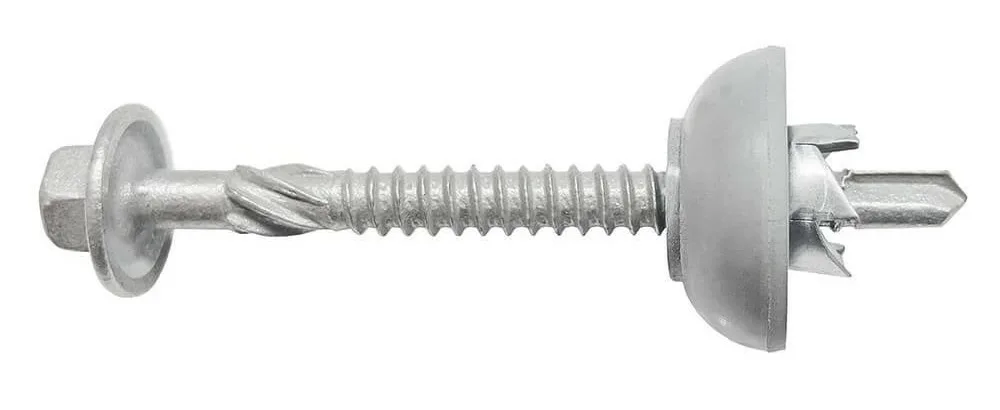

EPDM Roofing Fasteners

EPDM roofing fasteners incorporate rubber washers made of Ethylene Propylene Diene Monomer (EPDM), renowned for their waterproofing and weather-resistant properties. These fasteners are pivotal in roofing applications, securing materials like roofing membranes and metal panels while preventing water intrusion and maintaining the roof’s integrity, especially in regions prone to heavy rainfall or harsh weather. Their exceptional resistance to UV radiation, temperature fluctuations, and environmental conditions ensures long-lasting, reliable performance. In construction, EPDM fasteners find use in outdoor structures and cladding, where creating a watertight seal is essential. With their longevity and ability to withstand the elements, EPDM fasteners are a trusted choice for projects that require durability and effective weatherproofing.

Fiber Cement Roofing Fasteners

Fiber cement fasteners are specifically designed for use with fiber cement siding and related materials. These fasteners are typically corrosion-resistant, as fiber cement can be found in exterior applications where exposure to the elements is common. They come in various types, including screws and nails, and are engineered to securely attach fiber cement siding to the underlying structure. Fiber cement fasteners help maintain the integrity of the siding while ensuring it remains in place, even in adverse weather conditions.

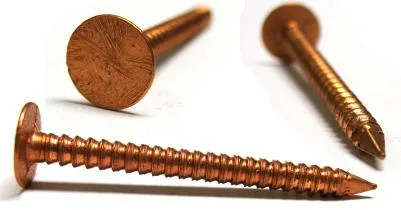

Copper Roofing Fasteners

Copper roofing fasteners are selected not only for their durability but also for their distinctive aesthetic appeal. Over time, they develop a characteristic greenish patina that imparts a unique and elegant charm to the roof. Their high resistance to corrosion is particularly advantageous in architectural and historical roofing projects, where visual appeal plays a prominent role. Copper fasteners are often the preferred choice when the aesthetics of the roof are a central concern, offering both longevity and a visually striking appearance.

Brass Roofing Fasteners

Brass roofing fasteners strike a balance between durability and a classic look. Although they may not match the corrosion resistance of stainless steel or copper, they maintain their visual appeal over time. Their traditional appearance makes them a popular choice for decorative and architectural roofing applications, contributing a touch of sophistication and style to the roof while still providing a reasonable level of resistance to corrosion.

Plastic Roofing Fasteners

Plastic roofing fasteners are made from synthetic polymers such as polyethylene or polypropylene. They offer a lightweight, cost-effective, and corrosion-resistant option for roofing. Their low weight is beneficial when minimizing structural load is crucial. These fasteners are especially attractive for budget-conscious projects, providing reliable performance without the premium cost of some other materials. Additionally, their non-corrosive properties ensure they can withstand moisture and humidity, making them a versatile choice for various environments.

Lead Roofing Fasteners

Lead roofing fasteners, on the other hand, are known for their exceptional durability and malleability. They can be shaped and molded to fit the contours of different roofing materials, especially in applications involving custom or complex roof shapes. Furthermore, lead is renowned for its weather resistance, capable of enduring even the harshest conditions. This makes it ideal for creating watertight seals and flashing around roof penetrations, such as chimneys, vents, and skylights, significantly reducing the risk of leaks in critical areas of the roof.

Factors to consider for selecting the right materials for roofing fasteners

Selecting the right materials for roofing fasteners is crucial for the durability and safety of your roof. Here’s a step-by-step guide on how to do it:

1. Roofing Material Compatibility: Different roofing materials have varying requirements for fasteners. For instance, metal roofs often require specialized screws and washers that are designed for metal-to-metal connections, while asphalt shingles may use different types of nails. Compatibility ensures that the materials won’t react chemically, which can lead to weakening and corrosion over time.

2. Environmental Conditions: The geographical location of the building plays a significant role in fastener material selection. Coastal areas with high salt exposure require materials with excellent corrosion resistance. Areas prone to heavy winds may necessitate fasteners with superior holding power to prevent wind-driven damage.

3. Corrosion Resistance: Choose fasteners that are resistant to corrosion. Stainless steel, aluminium, and galvanized steel are popular choices. The higher the grade of stainless steel, the better its corrosion resistance.

4. Strength and Holding Power: The fasteners must possess the strength required to secure the roofing material effectively. Inadequate holding power can lead to leaks, loose shingles, or tiles, and even structural damage in severe cases.

5. Weight of Roofing Material: The weight of the roofing material, whether it’s lightweight shingles or heavier tiles, impacts the fastener selection. The fasteners must be capable of supporting the weight without causing damage to the roof structure.

6. Aesthetic Considerations: While often overlooked, the appearance of roofing fasteners matters. Using materials that blend in with the roofing material and provide a clean, finished look enhances the roof’s overall aesthetics, especially in visible areas.

7. Budget: Budget constraints may influence material choices. While higher-quality, corrosion-resistant fasteners may have a higher initial cost, they can provide long-term savings by reducing the need for maintenance and premature replacements.

8. Local Building Codes: Compliance with local building codes and standards is essential. Regulations may dictate specific requirements for roofing fasteners, such as their type, size, or load-bearing capacity, and ensuring compliance is crucial for a safe and legally sound roofing installation.

9. Consult a Professional: If you’re uncertain about the best fastener choice for your specific roofing project, it’s a good idea to consult with a roofing professional or contractor. They can offer expertise based on your unique circumstances.

Conclusion

Choosing the right materials for roofing fasteners is an important decision that impacts the longevity and performance of your roof. Regular maintenance and professional installation are equally important to ensure the reliability of your roofing system. Making informed choices regarding roofing fastener materials is a key step in preserving the integrity and value of your roofing.

Source: screwexpert.com, roofix.in, bdnfasteners.in, slgfasteners.com