Cold recyclers have been a prime choice for the preparation of asphalt pavement on-site. With the cold recyclers, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement, and water. The result is a homogeneous material that can be used to directly repave the surface. This will allow for a more consistent and structurally sound asphalt base when the material is placed back onto the road surface. Because this is a “cold” process the material is slightly more porous than one would have from a hot mix material. In cold recycling, the damaged layers are milled, placed and compacted again, thus bearing capacity of roads can be optimized to new parameters It preserves as many properties of roads as possible. Considering all these given advantages, Cold Recycles are in huge demand in the market.

REMA cold recyclers are one the most effective and digitally enhanced construction machinery available today in the market. The company was founded in 2000. They are a famous supplier of Cold Recycler and Soil Stabilizer Road Machines. It is located in the Xuzhou economic development zone. The company’s cold recyclers are now available in India through Neha Infra Services.

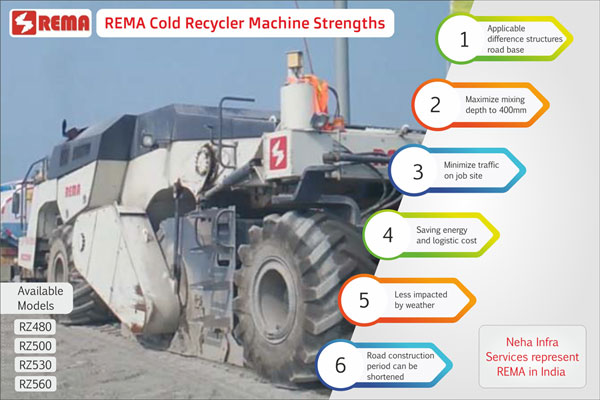

REMA cold recycler product range and advantages

The company is a famous supplier of Cold Recycler and Soil Stabilizer Road Machines The popular product models of the company includes – RZ480, RZ500, RZ530, RZ550, RZ560. RZ580. WR2300W. RZ2300D. RZ2500 series Cold Recycler and WB21,WB21H, WB25, WB25H,WBZ23 series Soil Stabilizer. We have focused on the company’s cold recycler machines.

The advantages of REMA Cold Recycler Machine are-

- Applied to different structures road base lays including that of bitumen cement, bitumen-soil, cement-stabilizing-macadam, etc.

- Maximize mixing depth to 400mm

- Re-use one hundred percent old construction material, with quite fewer new material- lime or cement required

- Minimize traffic on job site

- Saving energy and logistic cost comparing with using mixing plant f) Can be used as a Soil Stabilizer machine

- Road construction period can be shortened by 30 to 50 percent compared with traditional paving way

- Less impacted by weather, work can be resumed right after rain stops

REMA Cold Recycler Machine – Key Parts

- Cummins Diesel Engine.

- Milling and mixing rotor drive, operating drive and injection system all use the full hydraulic system of German Sauer Danfoss/ Linde, this ensures a higher and more reliable performance of the whole machine.

- Pressurized hydraulic oil tank with German imported oil filter effectively prevents oil tank pollution and pump suction air, ensures the reliability of the whole hydraulic system long term clearance, which guarantees the long life of the hydraulic pump. The machine can be used in high altitudes areas.

- Highly precise (water) injection system uses electronic controller, with digital display, most types of Recyclers have configured with self- priming pumps.

- Comprehensive use of H-type international standard tube fittings and reliable global standard hose, makes the whole hydraulic tube system high reliability.

- Different gears options for working speed, designed for difficult working conditions of roads, gears options for travel speed are also available for different travel demands between job sites and different job working conditions.

- Large luxury cab, piping under cab floor is accurately arranged, with the rubber gasket, good sealing performance, equipped with air conditioning, comfortable driving environment; adjustable seat, ergonomically

Rema company has several years engaged in the professional development of road engineering machinery and manufacturing industry experts. They also have rich experience in product design and application, in the stabilized soil mixing plant and pavement cold recycling applications accumulated in more than ten years of experience in application development.