As per the Indian Standard Specification IS 4926:2003,” Concrete mixed in a stationary mixer in a central batching and mixing plant or in a truck-mixer and supplied in fresh condition to the purchaser either at the site or into the purchaser’s vehicles.” Ready-mix concrete (RMC) is a ready-to-use material, with a predetermined mixture of cement, sand, aggregates and water. RMC is a type of concrete manufactured in a factory according to a set recipe or as per specifications of the customer, at a centrally located batching plant. Most of ready mixed concrete is currently manufactured under computer controlled operations and transported and placed at project sites using sophisticated equipment and methods. It is delivered to a worksite, often in truck mixers capable of mixing the ingredients of the concrete on route or just before delivery of the batch. The use of the RMC is facilitated through a truck-mounted boom placer that can pump the product for ready use at multi-storied construction sites. A boom placer can pump the concrete up 80 meters. Ready mix concrete is usually ordered in units of cubic yards or meters. It must remain in motion until it is ready to be poured, or the cement may begin to solidify. The Ready mix concrete business in India is in its infancy. Where as in developed countries, nearly 70 percent of cement consumption is in the form of ready mix concrete and 25 percent in the form of recast, in India, ready mix concrete accounts for less than 5 percent and as much as 82 percent of cement consumption is in the form of site-mixed concrete. While 70%of cement produced in a developed country like Japan is used by Ready Mix concrete business there, here in India, Ready Mix concrete business uses around 2% of total cement production. The share of RMC is expected to go up from present levels of around 5 percent of the total cement production to the global average of 70 percent, according to industry players.

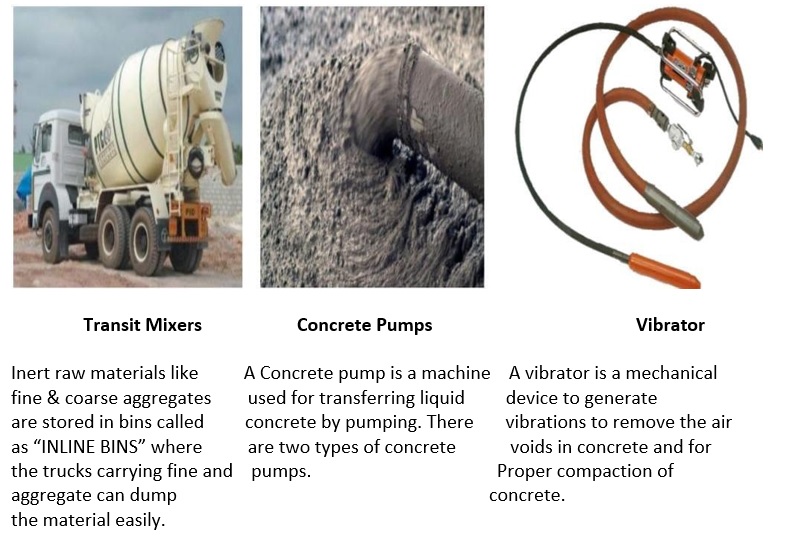

EQUIPMENTS REQUIRED IN RMC

MATERIALS USED IN RMC

TEST CARRIED OUT ON RMC

All the ingredients used for the preparation of the concrete are thoroughly tested for their quality and physical properties in a well-equipped laboratory attached to the plant for conformity to relevant Indian Standard Codes.

PROCESS OF READY MIX CONCRETE

APPLICATIONS OF READY MIX CONCRETE (RMC) IN THE CONSTRUCTION INDUSTRY

FEATURES OF READY MIX CONCRETE (RMC)

- Better quality concrete is produced.

- Elimination of storage space for basic materials at site.

- Elimination of Hiring plant and machinery.

- Wastage of basic materials is avoided.

- Labour associated with production of concrete is eliminated.

- Time required is greatly reduced.

- Noise and dust pollution at site is reduced.

- No wastage on site.

- Environment friendly.

SCOPE OF READY MIX CONCRETE

- Major concerting projects like dams, roads, bridges, tunnels, canals etc.

- For concreting in congested areas where storage of materials is not possible.

- Sites where the intensity of traffic makes problems.

- When supervisor and labour staff is less.

- To reduce the time required for construction etc.

- Huge industrial and residential projects.

GROWTH OF RMC CONSUMPTION COMPARED TO CEMENT PRODUCTION: Table-1 Year wise growth of RMC in Indian Market

| No | Year | Cement demand in Million Tons | Total concrete requirement in million m3 | Concrete requirement for Major projects in million m3 | Concrete requirement in rural areas in million m3 | Concrete requirement within domain of RMC in million m3 |

| 1 | 2006-07 | 145 | 282 | 55 | 96 | 131 |

| 2 | 2007-08 | 158 | 308 | 60 | 104 | 144 |

| 3 | 2008-09 | 172 | 335 | 66 | 113 | 156 |

| 4 | 2009-10 | 187 | 364 | 72 | 123 | 169 |

| 5 | 2010-11 | 204 | 397 | 78 | 134 | 185 |

| 6 | 2011-12 | 223 | 435 | 85 | 146 | 204 |

| 7 | 2012-13 | 243 | 474 | 93 | 159 | 222 |

| 8 | 2013-14 | 262 | 511 | 100 | 171 | 240 |

| 9 | 2014-15 | 283 | 522 | 108 | 184 | 260 |

| 10 | 2015-16 | 306 | 596 | 117 | 198 | 281 |

CONCLUSIONS

Ready Mix Concrete is a modern technique of production of concrete in massive quantities away from the actual site of placing. It is very useful where demand of concrete is very high and construction sites are in congested areas, where mixing on site is not possible due to lake of storage place. RMC is ready to use material. It is widely adopted throughout the world. It gives higher strength to the structure and it also provides higher Durability to the structure. It reduces noise pollution as well as air pollution. The Supervisory and labour costs associated with the production of RMC is less, and the quality of concrete is high. It is suitable for huge industrial and residential projects where time plays a vital role. So ultimately it provides economy in the construction and better finish to the structure. Hence the advantages of RMC are realized by engineers and contractors in the construction industry.

Authored By;