Achieving a leveled surface for Very Narrow Aisle (VNA) floors in a warehouse is essential for ensuring operational efficiency and safety. Uneven floors can cause instability for Material Handling Equipment (MHEs), misalign racks, and slow down movement, which negatively impacts productivity and increases maintenance costs.

This case study focuses on a warehouse that faced significant VNA floor leveling problems, leading to substantial operational challenges. To address these issues, Avcon Technics Private Limited used its engineered resurfacing products. The company provided turnkey design and engineered concrete flooring services, encompassing floor assessment, design, and installation to achieve the required floor specifications.

Clients Problem

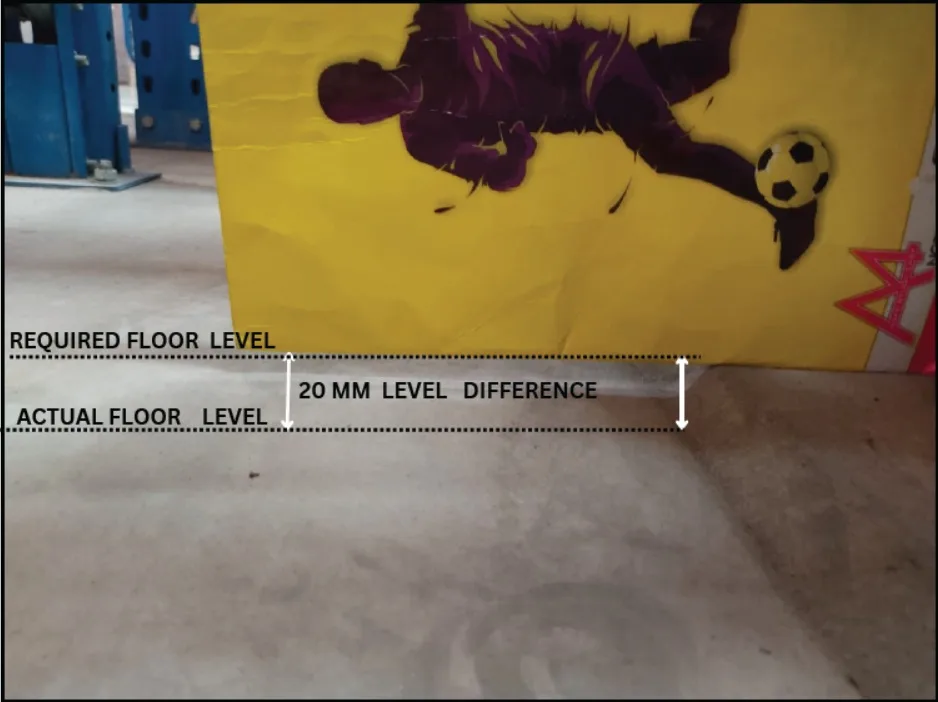

As shown in the picture, the client encountered a significant issue with a 20mm floor level deviation between the required and actual floor levels in their warehouse. This deviation caused operational challenges, particularly for Very Narrow Aisle (VNA) systems, which depend on a flat, level surface that typically meets DM1 or DM2 specifications.

The 20mm level difference led to difficulties in moving Material Handling Equipment (MHE) across the warehouse floor. In VNA systems, where precise movement in tight spaces is necessary, any irregularity in the floor can result in inefficiencies. These irregularities could cause damage to MHE, stock, and racking systems, increasing maintenance costs, reducing material handling efficiency, and raising the risk of downtime.

In addition, poor floor flatness accelerates wear and tear on MHEs, leading to frequent and costly repairs. This not only raises maintenance expenses but also shortens the lifespan of equipment. To resolve these challenges and create a safe, efficient, and reliable warehouse floor, the client required a solution that would effectively address the floor’s unevenness.

Solution to the Problem: Resurfacing with Avcrete LMC

To address the 20mm level difference in the floor, a resurfacing solution was required. After evaluating different options, Avcrete LMC (Light Modified Concrete) and Avcrete LMC T5 were selected as the ideal choice.

The floor resurfacing of 20mm was done using Avcrete LMC. Avcrete LMC T5, a thin yet heavy-duty resurfacing screed floor mortar known for its high abrasion resistance, was used for the repair and leveling process. This durable solution effectively addressed the floor’s unevenness, providing a durable leveled surface that can withstand heavy traffic and wear.

Advantages of the AVCRETE – LMC

- High impact and high abrasion-resistant thin screed mortar (min thickness 12mm).

- Polishable system for a smooth finish.

- Single-component, pre-blended dry mortar for easy application.

- Ideal for heavy-duty industrial floor resurfacing.

- Suitable for re-surfacing of damaged or worn-off floors.

- Can be used for floor level correction to meet flatness criteria.

Advantages of the AVCRETE LMC – T5

- Ultra-thin (5mm) heavy-duty floor screed mortar.

- High abrasion resistance, making it suitable for high-wear areas.

- High bond and flexural strength for durability.

- Can be used as a final finished surface or over-coated.

- Ideal for both new and old surfaces (5-10mm thickness).

- Available in various colors to match aesthetic needs.

- Meets Abrasion Class AR2 (as per BS 8204).

Steps in Implementing the Solution

The floor resurfacing process involved multiple stages, with each step meticulously planned to ensure that the new floor met the required VNA specifications and provided a durable, level surface for safe and efficient operations. Steps Taken to Achieve a Leveled VNA Floor in the Warehouse involved:

- Surface Preparation through Scribbling: The floor was initially prepared by scribbling to create a rough texture, ensuring better adhesion for the resurfacing mortar.

- Vacuum Cleaning: Once the scribbling was complete, the floor was thoroughly vacuumed to eliminate any dust, debris, or loose particles.

- Applying Bonding Agent: A layer of Roc Prim bonding agent was applied to the floor, forming a strong bond between the existing surface and the new mortar layer.

- Laying Avcrete LMC: The Avcrete LMC was applied using screed tools to correct the 20mm level difference and ensure a smooth, even surface.

- Final Finishing: After the Avcrete LMC application, Power Trowels were used to refine the surface, achieving a perfectly smooth and level finish.

The final floor finish was completed, fully meeting VNA specifications for flatness and levelness.

With decades of experience in engineered flooring solutions, Avcon Technics demonstrated its ability to address complex flooring challenges with precision. Their expertise in the design, assessment, and implementation of high-quality resurfacing solutions enabled the client to achieve a flawless, leveled warehouse floor, ensuring operational efficiency and reduced maintenance costs.

For more details, visit-https://avcontechnics.com/