Construction projects demand rigorous planning, accuracy, and efficiency when it comes to MEP systems. Traditional design tools often lead to a range of challenges. Workflows tend to be siloed, with disconnected designs created for mechanical, electrical, and plumbing systems. This fragmented approach creates efficiencies and coordination issues.

With the traditional approach without BIM, clashes between trades often go undetected, as legacy processes lack in-depth visualization. This leads to costly reworks and construction. Reliance on 2D design increases inaccuracies, leading to resource and material waste.

In the current building landscape, BIM offers the most advanced method to streamline MEP design and coordination. It improves collaboration, facilitates clash detection, and data-driven decision-making. Based on a study, 60% of organizations implement coordination operations using BIM-driven tools to improve MEP coordination.

MEP Systems and Their Critical Role in Building Functionalities

MEP or mechanical, electrical, and plumbing systems make a building habitable. Mechanical systems include heating, ventilation, and air conditioning for air quality and climate control; electrical systems provide power distribution, lighting, communications, and safety, while plumbing systems provide water lines, gas lines, and drainage.

Well-designed MEP systems ensure safety, occupant comfort, and building efficiency. This is why MEP coordination is critical in mitigating conflicts and ensure improved building functionality.

Traditional Design Challenges: Inefficiencies, Coordination Issues, Errors, and Rework

Legacy MEP design techniques often face a series of roadblocks that impede progress success. Here’s an analysis of each issue.

- Coordination issues: Design teams working in silos make it difficult to coordinate MEP systems, leading to clashes and spatial issues on-site.

- Inefficiencies: Dependency on 2D drawings and manual techniques leads to time-consuming processes and delays in data exchange.

- Rework: The detection of errors and clashes during onsite construction causes rework, frustration, and project delays for every team and stakeholder.

- Errors: Disconnected drawings and manual miscalculations are prone to human error, which results in error-prone designs, unsynchronized components, and budget overruns.

BIM as a Transformational Technology in the Construction Industry

The construction landscape is undergoing a transformation with BIM at the lead. BIM overcomes the limitations of legacy 2D drawings to create intelligent and data-rich 3D models. 2D drawings extracted from BIM 3D models are accurate, information rich, and always updated to the moment they are extracted.

Tools within the BIM ecosystem support collaboration across multiple trades and help architects, contractors, and engineers view the entire MEP system in virtual space before fabrication and installation begin. BIM connects workflows, reduces errors, and perfects design to promote efficient and cost-effective construction.

BIM Fundamentals for MEP Systems

BIM objects are intelligent, data-rich representations of MEP components (including ducts, pipes, fixtures, electrical conduits, etc.)

BIM goes beyond processes and 3D shapes. Data-rich and intelligent representations of actual MEP components like ducts, pipes, electrical conduits, and fixtures include information like dimensions, materials, manufacturing data, and performance characteristics. This information embedded within BIM objects shows precise size, interference detection, and material usage, and enables seamless collaboration.

3D modeling in BIM: Precise spatial coordination and visualization

3D BIM modeling capabilities improve MEP design by offering a series of advantages. MEP engineers can visualize complex MEP systems within a coordinated and shared platform. It makes placing pipes, ducts, electrical components, and other systems precise and easier.

Eliminating clashes early in the design phase enriched by visualization improves design validity, reduces costly site issues, and ensures uninterrupted integration of MEP systems.

The Importance of BIM LOD (Level of Development): Detail and information progression throughout design stages

The concept of BIM LOD establishes a framework for refining information and detail in BIM MEP objects throughout design and construction stages, from LOD 100 (conceptual) to LOD 500 (as-built). Initially, objects are basic, but gain precise details, material specs, and manufacturer information as design progresses.

Standardized LOD ensures stakeholder understanding, continuous collaboration, informed decision-making, and reduced errors. Specifying LOD helps project managers ensure the 3D BIM model meets project expectations at every stage.

Optimizing MEP Designs with BIM

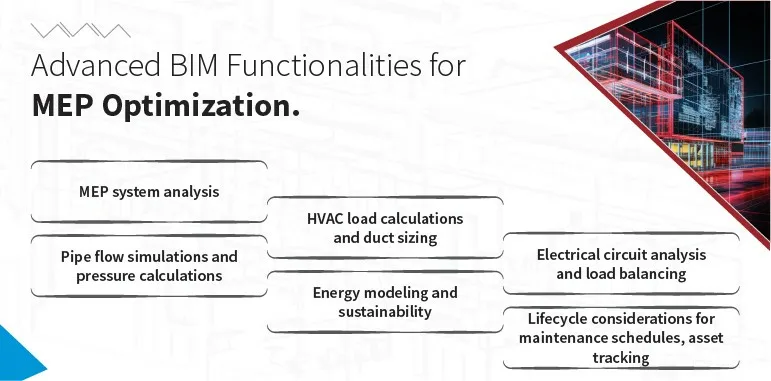

MEP system design: Using BIM for accurate load calculations, equipment sizing, and system routing

BIM tools have revolutionized MEP systems design, enabling precise load calculations and sizing of HVAC, electrical, and plumbing components using real-world data. BIM enhances routing of smart systems, allowing designers to visualize pipes, ducts, and conduits in 3D, facilitating clash detection and reducing spatial conflicts. Its ability to analyze multiple design scenarios helps MEP engineers optimize routing, material use, and cost savings.

An engineering contracting company created a coordinated and clash-free MEPF model for a hospital project in Ireland. The data-rich 3D model helped the client achieve 98% FTR deliverables and cost savings based on quick and error-free installation of MEP equipment.

Energy analysis and simulation: Assessing a building’s energy performance within the BIM environment

BIM, using tools like Revit, enables MEP engineers to perform energy analysis and simulations by integrating building data. This helps calculate energy use, identify improvements, and evaluate design options, optimizing for efficiency and sustainability.

Sustainable design integration: Evaluating design choices for energy efficiency and green building standards (e.g., LEED)

BIM enables sustainable building design by allowing preconstruction assessment of energy efficiency, water conservation, and material choices. Tools like Revit help calculate environmental impacts and support certifications like LEED, promoting informed decisions to enhance performance and achieve sustainability goals.

Using BIM, building projects can reduce energy consumption by 30%

The BIM Model as Single Central Data Repository

- Geometric information: A 3D BIM model acts as a dynamic data repository for detailed geometric information of MEP components, enhancing accuracy and spatial coordination. This central model facilitates proactive interference detection and resolution, streamlining MEP design and construction.

- Non-geometric attributes: A 3D BIM model stores non-geometric data of MEP elements, including specifications, performance, manufacturer info, and maintenance needs. This centralized data source enhances decision-making, material procurement, operations, and collaboration throughout the building lifecycle.

- Easing MEP collaboration: BIM fosters MEP design collaboration by offering a unified platform where architects, contractors, and engineers work together on a shared 3D model. Real-time updates ensure all teams have current information, enhancing coordination, addressing issues, and minimizing miscommunication.

- Data-driven decision making: BIM harnesses the power of the data embedded within the 3D model. Designers can use these data to run simulations like energy analysis, airflow modeling, and lighting studies. These simulations deliver valuable insights into system performance under diverse conditions. This helps designers use design options and make informed calls.

Clash Detection and Resolution: The Core of BIM-Enabled Coordination

Automated clash detection: BIM’s automated clash detection capability changes the game of MEP coordination. It uses sophisticated rule sets and algorithms to assess the 3D BIM model. These algorithms are used to compare the spatial relationships and geometry of MEP elements with structural components, architectural parameters, and clearance locations. Clash detection identifies potential conflicts, including ducts intersecting beams, pipes running close to walls, or insufficient clearance around electrical systems.

A general contracting company from the Middle East built a clash-free MEP 3D model with coordination drawings for an airport project. Upon handover of the required deliverables, the client could save $7 million with 100% installation of MEP equipment and reduction in change orders.

Visualizing clashes: 3D representation of clashes within the BIM environment for easy resolution: Clash detection with BIM isn’t just about problem identification, but visualization. Clashes are highlighted in powerful BIM model auditing platforms like Navisworkswhile pinpointing the exact nature and position of the interference. This visualization helps designers understand issues, analyze severity, and create the best solutions.

Best Practices and Implementation

Importance of BIM standards and protocols: Ensuring consistent data exchange and workflows.

- Flawless data exchange: Define how information within the 3D BIM model is formatted and structured. This helps architects, engineers, and contractors collaborate effectively and prevent loss of information.

- Cohesive workflows: Compliance with protocols ensures every stakeholder follows standardized procedures to create, update, and collaborate on 3D models. It helps reduce reworks, mitigates errors, and delivers team efficiency.

- Project-wide compatibility: BIM standards support data sharing from design to construction and facilities management, leading to BIM model longevity.

BIM software selection: Considerations for MEP-specific functionalities.

Selecting the right BIM tools can maximize design and coordination efficiency. Select solutions that offer sophisticated MEP modeling tools to handle ductwork, piping, and electrical systems. Consider tools that provide automated clash detection, MEP system routing, and calculations like pressure drops, load assessment, etc. Look for platforms that support interoperability for effective collaboration and information exchange.

Industry standards and collaboration (e.g., IFC, COBie): Enabling information exchange across different software platforms.

Industry standards such as COBie and IFC play a key role in driving collaboration within BIM workflows. IFC, or Industry Foundation Classes, delivers a neutral and open file format to send BIM data between various software utilized by multiple stakeholders.

COBie improves facilities management with the standardized handover of facilities management data. These standards guarantee the accessibility and usability of project data for the entire building cycle.

BIM powered MEP systems: Advancements and innovations to expect for efficiency and sustainability

AI-driven design optimization: Artificial intelligence will be increasingly embedded within BIM processes. AI algorithms would analyze substantial amounts of data to create the best design prototypes, suggest MEP layouts, flag potential issues, and automate redundant activities. This would lead to greater efficiency, sustainability, and cost-effective projects.

Greater focus on energy efficiency and sustainability: BIM will lead the way to improving energy efficiency and sustainability through data-driven building design. Advanced analysis tools and simulations would support engineers in enhancing building performance, lowering carbon emissions, and promoting green building certifications.

IoT and Smart building: 3D BIM models merge with IoT devices and connect MEP systems through a network of sensors. This would enable real-time monitoring, predictive maintenance, and smart optimization, leading to greater occupant comfort.

AR and VR: AR and VR would become more significant in MEP workflows to augment design visualization, coordination, and onsite inspection.

Conclusion

BIM has transformed MEP design and coordination by introducing a collaborative and data-driven approach to substitute legacy 2D workflows. It has significantly improved accuracy, efficiency, and sustainability within building projects. Preemptive clash detection, improvements in system design, integrated workflows, and simulations have helped MEP engineers and consultants make informed decisions at multiple building stages.

As engineering firms continue to embrace BIM processes and tools, we will see modern construction executed with higher precision, lower carbon footprints, and greater performance.

About Author:

The author is a BIM MEP expert with over 10 years of experience in the mechanical BIM field. Having worked on multiple MEP projects worldwide, he is always looking for ways to enhance design quality and project productivity through technology interventions and process excellence. His exposure to various residential and commercial sectors, including hotels, airports etc. make him a go-to authority in the BIM MEP space.