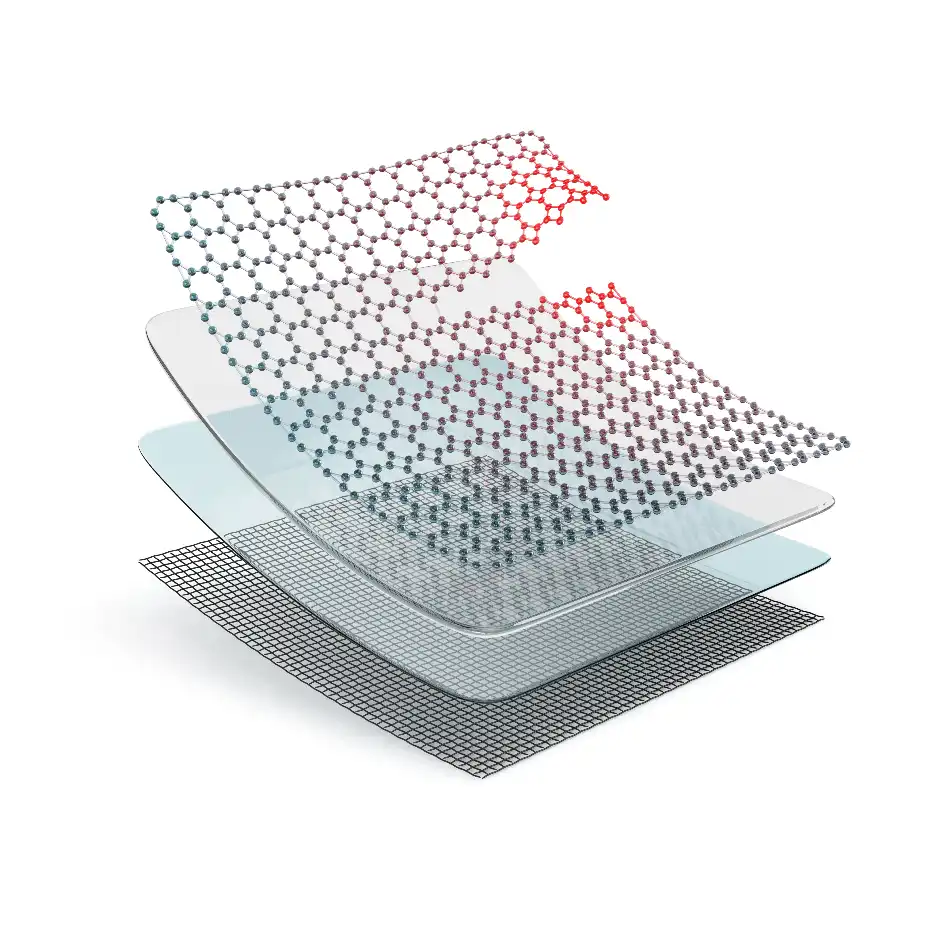

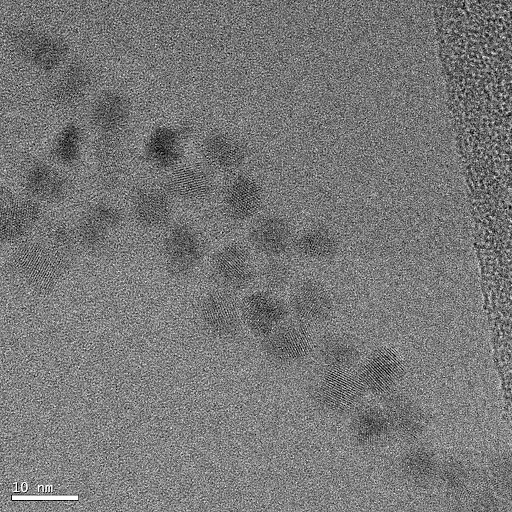

Nanotechnology allows for the control and intervention in material properties at the nanoscale and, therefore, at the molecular level. Nanotechnology is an emerging field of science related to the understanding and control of matter at the nanoscale, i.e., at dimensions between approximately 1 and 100 nm. At the nanoscale, unique phenomena enable novel applications. Nanotechnology encompasses nanoscale science, engineering, and technology that involve imaging, measuring, modeling, and manipulating matter at this length scale.

It is still at the fundamental research level and, therefore, of limited practical development, with extremely encouraging results as far as the improvement of some or all the properties of concrete:

- mechanical and electrochemical properties (strength, ductility, electrical conductivity, corrosion inhibition)

- concrete durability (watertightness)

- surface protection of the reinforcement through application of surface coatings (nanomodified reinforcement)

- concrete technology (workability)

- long-term maintenance and monitoring (self healing of micro cracks, the ability to search and detect moisture presence, temperature, stress).

Concrete, the most ubiquitous material in the world, is a nanostructured, multiphase, composite material that ages over time. It is composed of an amorphous phase, nanometer- to micrometer-size crystals, and bound water. The properties of concrete exist in, and the degradation mechanisms occur across, multiple length scales (nano to micro to macro) where the properties of each scale derive from those of the next smaller scale. Nanoengineering of concrete can take place in one or more of the three locations such as (a) in the solid phases, (b) in the liquid phases, or (c) at the interfaces between liquid–solid and solid–solid.

The mechanical behavior of concrete materials depends to a great extent on structural elements and phenomena that are effective on a micro- and nanoscale. The size of the calcium silicate hydrate (C-S-H) phase, the primary component responsible for strength and other properties in cementitious systems, lies in the few nanometers range (Taylor, 1997). The structure of C-S-H is much like clay, with thin layers of solids separated by gel pores filled with interlayer and adsorbed water. This has a significant impact on the performance of concrete because the structure is sensitive to moisture movement, at times resulting in shrinkage and consequent cracking if accommodations in element sizes are not made. Hence, nanotechnology may have the potential to engineer concrete with superior properties through the optimization of material behavior and performance needed to significantly improve mechanical performance, durability, and sustainability.

Birgisson et al. (2010) identified the following key breakthroughs in concrete technology that are most likely to result from the use of nanotechnology:

- Development of high-performance cement and concrete materials as measured by their mechanical and durability properties;

- Development of sustainable concrete materials and structures through engineering for different adverse environments, reducing energy consumption during cement production, and enhancing safety;

- Development of intelligent concrete materials through the integration of nanotechnology-based self-sensing and self-powered materials and cyberinfrastructure technologies;

- Development of novel concrete materials through nanotechnology-based innovative processing of cement and cement paste; and

- Development of fundamental multiscale model(s) for concrete through advanced characterization and modeling of concrete at the nano, micro, meso, and macroscales.

Recent developments Nanotechnology in concrete

Nanotechnology based products have entered the market for reducing the permeability of concrete through the addition of nanomaterials in the form of solution. Due to the immediate improvement in the performance of the material during service (color stability, resistance to fungus development on the surface, durability), these products are targeting structural and architectural applications (concrete blocks, paving blocks, mortars). It is anticipated that the tremendous development in this field will no doubt also affect the construction industry and therefore cement and concrete, as well. Some of the developments are discussed below.

Nano-fume – a new ultrafine, powder admixture of amorphous SiO2 produced from fly ash, was used to prepare high strength concrete based on normal portland cement.

Nanometer-sized franklinite particles – obtained from electric-arc-furnace has shown superior concrete strength compared to that made with Portland cement alone.

Organo-modified montmorillonite particles – which are hydrophobic have shown immediate strength and commercial reduction coefficient of permeability of cement mortar and concrete.

Nano-cement portland cement – composition has a calcium silicate-based nanoparticles produced by flame spray synthesis has shown tenfold increase of initial reactivity compared to conventional portland cement.

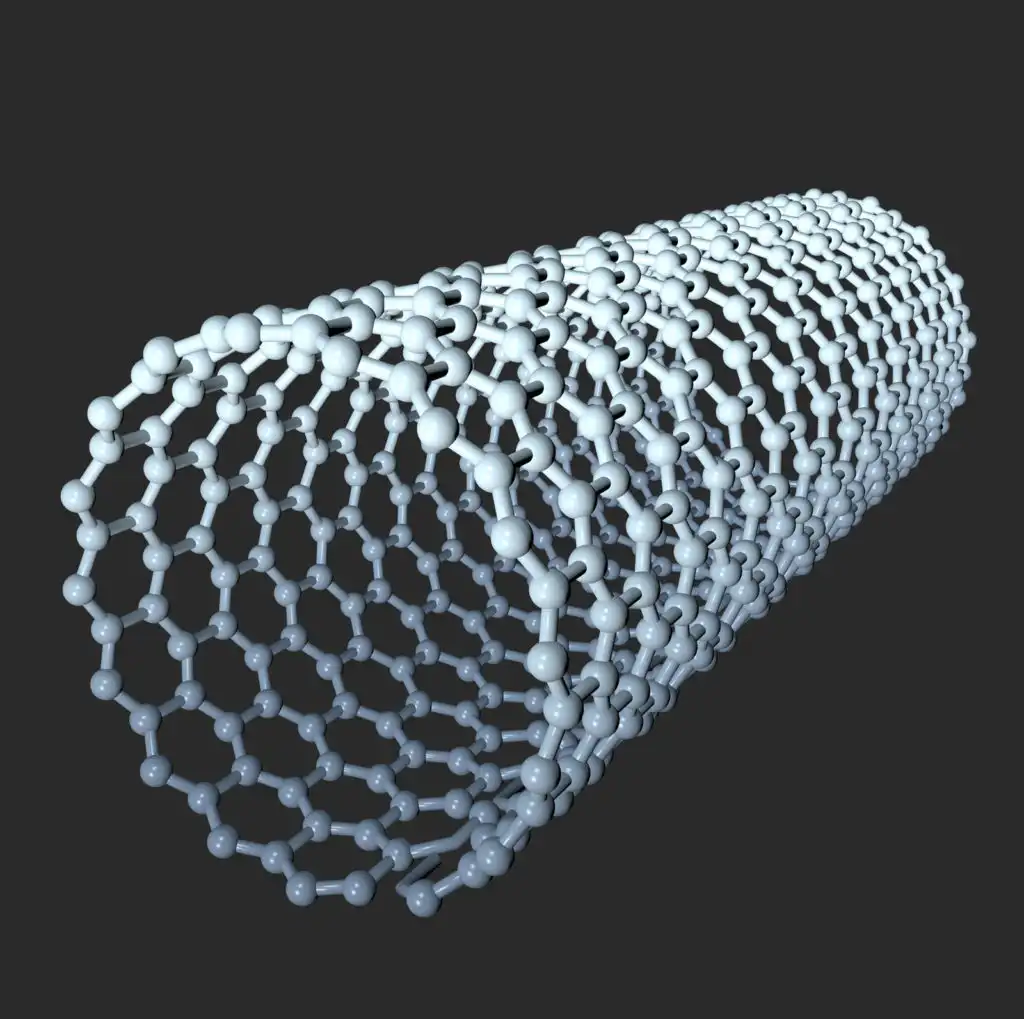

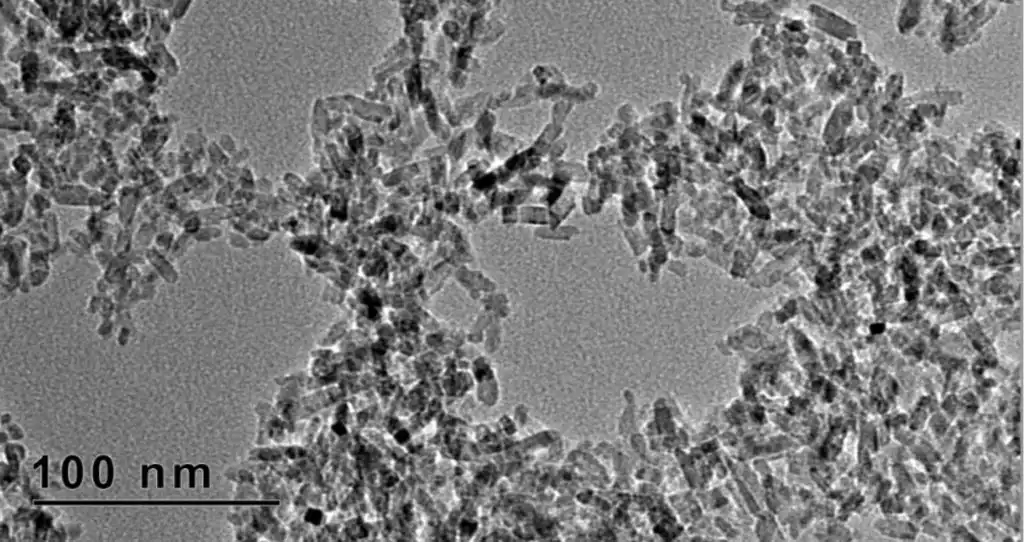

Carbon Nanotubes – it is used as nano reinforcements in cement based material exhibit extraordinary strength with moduli of elasticity of the order of TPa and tensile strength in the range of GPa.

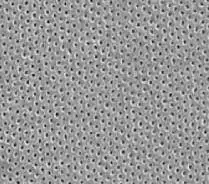

Nanoporous thin film – it is applied on aggregate surfaces before concrete mixing was found to be an effective way to improve the Interfacial Transition Zone and thereby improve the performance of concrete.

Self-healing polymers – this include Microencapsulated healing agent and catalytic chemical trigger added to cement mortar has demonstrated healing of concrete micro cracks

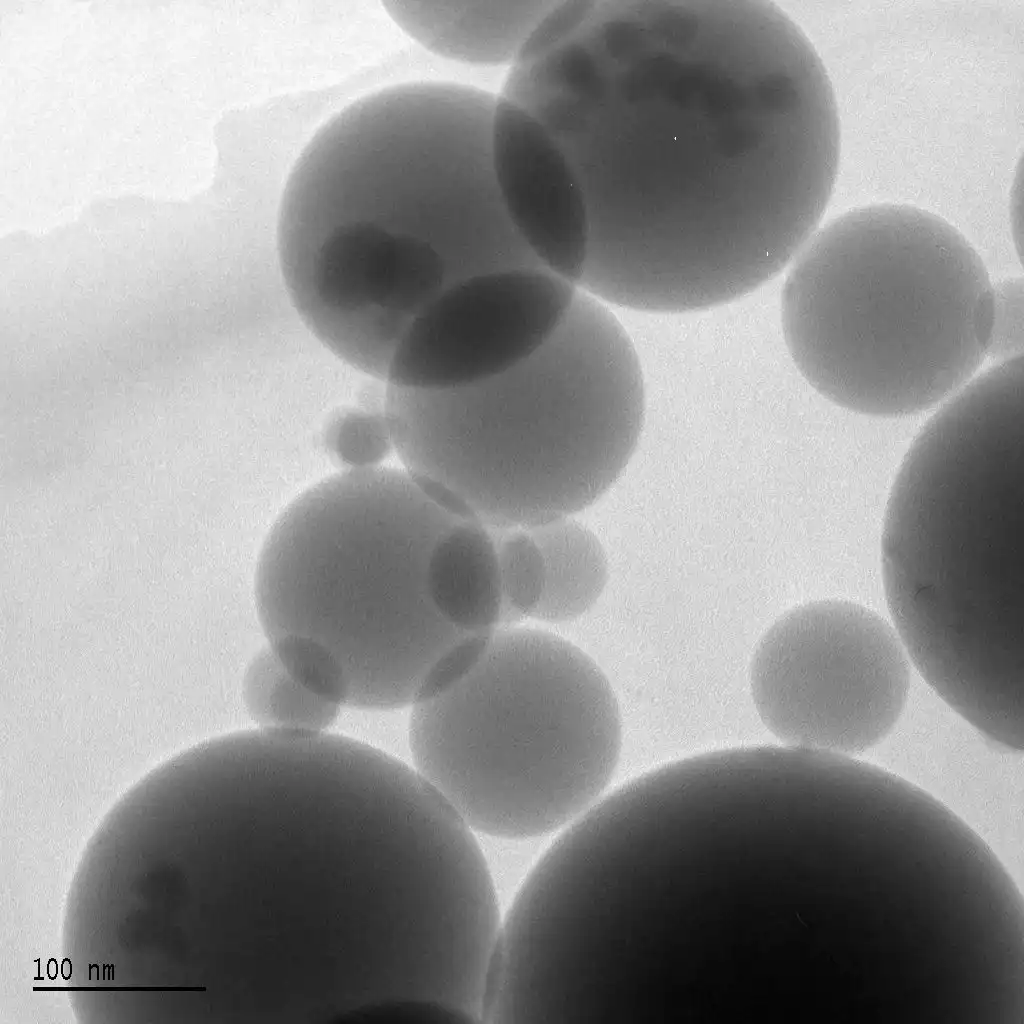

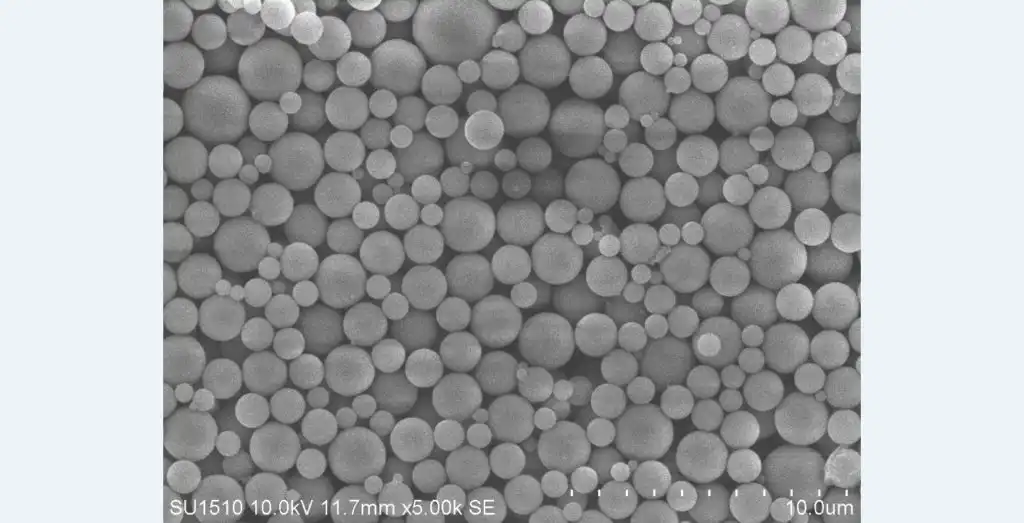

Silicon dioxide nanoparticles – it increases reinforcement in mechanical strength (in concrete); coolant, light transmission, and fire resistance (in ceramics); flame-proofing and anti-reflection (in windows).

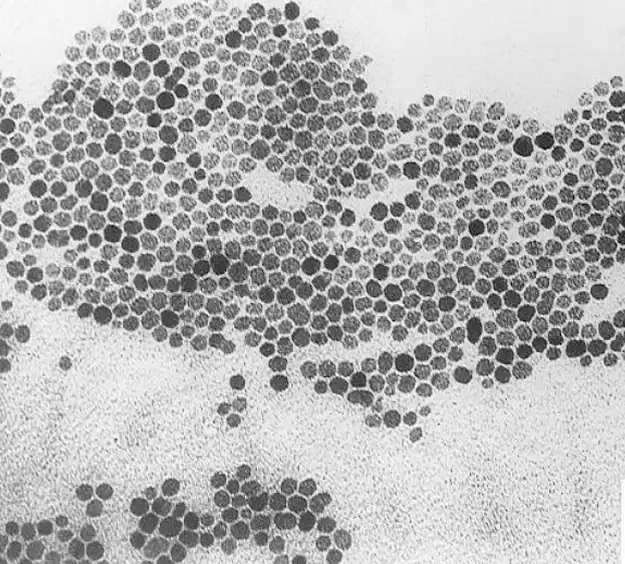

Titanium dioxide nanoparticles – it has great features such as rapid hydration, increased degree of hydration, and self-cleaning (in concrete); superhydrophilicity, anti-fogging, and fouling-resistance (in windows); non-utility electricity generation (in solar cells).

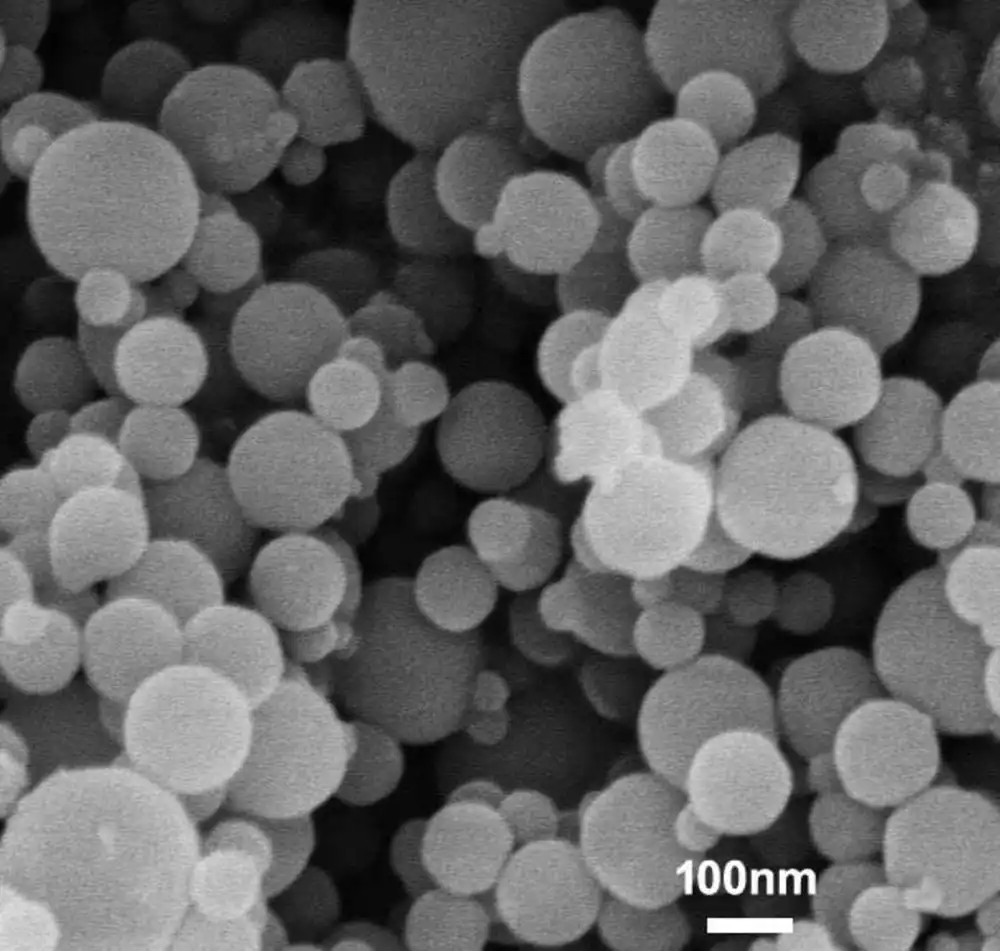

Iron oxide nanoparticles – used for the increased compressive strength and abrasion-resistant in concrete.

Copper nanoparticles – it offers weldability, corrosion resistance, and formability in steel.

Silver nanoparticles – well suited for biocidal activity in coatings and paints.

Quantum dots – these are effective electron mediation in solar cells.

The need of nanotechnology

Nanotechnology will take us in the construction industry and should be considered not only for enhancing material properties and functions but also in the context of energy conservation. This is a particularly important prospect since a high percentage of all energy used is consumed by commercial buildings and residential houses by applications such as heating, lighting, and air conditioning.

Nanoparticles of TiO2, Al2O3 or ZnO are applied as a final coating on construction ceramics to bring this characteristic to the surfaces. TiO2 is being used for its ability to break down dirt or pollution when exposed to UV light and then allow it to be washed off by rainwater on surfaces like tiles, glass and sanitaryware. ZnO is used to have UV resistance in both coatings and paints. Nanosized Al2O3 particles are used to make surfaces scratch resistant. These surfaces also prevent / decelerate formation of bad smells, fungus and mould.

“Nanotechnology could allow the development of materials with better insulation properties, intelligent structures capable of optimizing the use of energy. New insulating materials have been developed with the help of advances in nanotechnologies. These insulating materials are: nanofoams, nanostructured aerogels and vacuum insulated panels (VIPs).

Conclusion

Tremendous achievements have been reported on nanotechnology adoption on sustainable construction, but there are so much more to explore than has been achieved. Some of the advancements on the adoption of nanotechnology on sustainable construction, includes the enhancement of the rheology, strength and durability properties of concrete; which has been proved to be hinged on the nanoscopic characteristics of its constituent. Any modification at the nanoscopic level of concrete and its constituent influences its behavior, including its strength and durability characteristics. Hence, it is projected that the performance of concrete and sustainable construction materials in the future would be greatly enhanced by the application of nanotechnology to manipulate the atoms and molecules of these materials and their constituents at the nanoscale.

References – onlinepubs.trb.org, hcia.gr, nanowerk.com, reaearchgate.com, thebalancesmb.com, wikimedia.org, britannica.com, semanticscholar.org, azom.com, getnanomaterials.com, ec.europa.eu, intechopen.com, ssnano.com, elgalabwater.com, optics.rochester.edu, civilsnapshot.com