Whether your roof is a roof panel or a standing seam roof panel, it will have some exposed fasteners. The fasteners, therefore, must be durable to prevent perforation of the roof panels. A non-durable fastener will always begin to rust, even if painted. Avoid this by always using long-lasting fasteners in all exposed fastener locations. Failure to adhere to this could reduce the service life of your roof.

A fastener must be able to withstand all the environmental elements it is exposed to. These include UV degradation, salts from marine environments, acid from industrial pollution, rain, extreme heat, fumes and gases from within factories and plants, etc. While exposed to these conditions the washers must remain elastic, intact and watertight for the life span of the complete roofing system.

Fastener cost less than 3% of the Cost of the building & less than 1% of the cost of the total project. Yet, we see that people want to compromise of the Quality of such small item having such huge significance on the Sustainability of the Building. Therefore, it is always preferable to go for a proven expert for fastener works. One such group is Realm India.

Realm is committed to being a partner for the Roofing Industry. They work closely with all sections of the trade to understand your needs and seek out the finest fasteners from across the world making them available right at the client’s door step to assist increase your performance. REALM Intermediates Pvt. Ltd. was established in 1998. The company designs, develops and markets contemporary standard fasteners for the construction industry. It is also a trusted representative for both national and international manufacturers.

Understanding the need for a correct metal fastener for the construction industry

Realm realized long back that the fasteners used in construction can often determine the success or failure of a project. This insight led them to dedicate collective energies towards providing quality range of fasteners and value-added services designed to not only speed construction, improve structural reliability but also ensure performance under demanding weather conditions. The company is keen to support you with innovative solutions that increase your productivity, reduce risk and help you build your reputation as a contractor of choice.

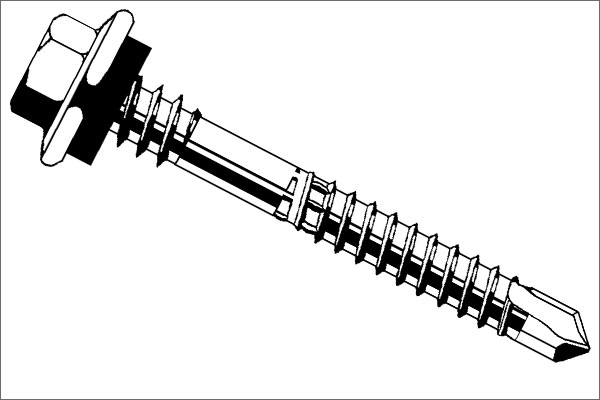

REALM has introduced ROOFIX Brand of Self Drilling Screws to the metal roofing market. It’s a perfect combination of renowned international design and India-specific customization. These screws are imported only from ISO certified companies across countries like Australia and in South East Asia. The company’s application specialists provide ready technical support in helping you pick the right product. They have a warehouse facility based out of Navi Mumbai that regularly delivers goods all across India.

The range includes Products for Fixing metal roofing, Cladding & Decking includes Screw solutions which can dramatically speed up the installation, improve building integrity and ensure performance under demanding conditions.

Roofix is manufactured in Taiwan. The Fastener is Factory Finished, involved in all the stages of manufacturing:

- Heading

- Forging

- Thread Rolling

- Heat Treatment

- Coating

- EPDM Washer Assembly

- Packaging & Distribution

The Quality Product is marketed all India and the neighbouring countries.

Specialized product range

The product range of Realm consists of three product types, namely, ROOFING Fasteners / Self Drilling Screws with ROOFIX Brand, DEKS Industries, Melbourne Based company dealing with EPDM Flashing products and DEKS EPDM Washers. Each of the product details are given below.

ROOFING Fasteners / Self Drilling Screws with ROOFIX Brand

- Cold Rolled SDS – Fasteners that drill upto 4.5mm thick Steel

- Hot Rolled SDS – Fasteners that drill upto 12mm thick steel

- Fibre Fix Screws

- PolyFix Screws – Used to Fix polycarbonate sheeting.

ROOFIX Self Drilling Fasteners Conforms and exceeds AS3566 – 2002 Class 3.

Self Drilling Screws Meeting the Australian & International Standard AS3566 Class (March 2002) which details as follows:

- Salt Spray Test Certificates (ASTM B117).

- 15 Cycles of Kesternich Test in accordance to DIN 50018. (Condensing the atmosphere containing Sulphur dioxide at level SFW 2.05.)

- Relative Humidity in accordance with ASTM D2247 for 1000 Hours.

- Test Cycle of 4 Hours of UltraViolet Radiation as per ASTM G154 for 2000 Hrs.

From the day we are born or create some material thing, decay sets in. This is caused by various reasons and in metal which affects the lives of most of us here today.

Corrosion has the ability to destroy business reputations, stain the proud structures Realm has built and limit them from providing customers a quality job. At REALM, ROOFIX SDS has a mission not just to make the best carbon steel fasteners available but to fight corrosion in an effective and affordable way supplying the trade and end users a quality product that fills the ‘corrosion gap” between yellow zinc and stainless-steel fasteners.

The coatings and features the company apply to roofing screws gives you the fixers, specifiers, roll formers and end users a product you can confidently use in the knowledge that it is technically developed to fight corrosion better than any other like fastener giving you

- an advantage over opposition,

- giving your clients peace of mind and an

- Opportunity to confidently warranty your work to match the cladding or beyond.

Realm’s Roofing self drilling fasteners meet the RoHS Compliance Definition.The definition and aim of the RoHS directive is quite simple. The RoHS directive aims to restrict certain dangerous substances commonly used in electronic and electronic equipment. Any RoHS compliant component is tested for the presence of Lead (Pb), Cadmium (Cd), Mercury (Hg), Hexavalent chromium (Hex-Cr), Polybrominated biphenyls (PBB), and Polybrominated diphenyl ethers (PBDE). For Cadmium and Hexavalent chromium, there must be less than 0.01% of the substance by weight at raw homogeneous materials level. For Lead, PBB, and PBDE, there must be no more than 0.1% of the material, when calculated by weight at raw homogeneous materials. Any RoHS compliant component must have 100 ppm or less of mercury and the mercury must not have been intentionally added to the component. In the EU, some military and medical equipment are exempt from RoHS compliance.

DEKS Industries, Melbourne Based company dealing with EPDM Flashing products which are used to seal cut-outs, chimneys, HVAC Ducts in Metal Building

- DEKS Premium / DEKS Original

- DEKS Strip

- DEKS Retrofit / Soaker

- DEKS Fast Flash

- DEKS Combo

- DEKS Washers

DEKS EPDM Washers used by the majority of Quality Fasteners company

- Cut washers / RING Washers – True Blue Low Carbon EPDM Washers

- Polycarbonate washers

- Weather Lok Washers

- Metal Bonded Washers / Multi Seal Washers

This thermoset membrane is compound from rubber polymer and is often referred to as rubber roofing. The American Society for Testing and materials (ASTM) classifies this material as an M Class Polymer. Ethylene and propylene derived from oil and natural gas, are organic building blocks of EPDM. When combined with diene to from the basic rubber matrix, the result is long-chain hydrocarbon with a backbone of saturated molecules and pendant double bonds. The Practical translation is ethylene, propylene and diene combine to form a large molecule that is very stable when exposed to sunlight, heat, ozone (UV) and moisture.

EPDM (Ethylene Propylene Dine Monomer) became the seal of choice with the leading roof fastener manufacturers. This terpolymer elastomer is particularly well suited for sealing washers due to its resistance to water, chlorinated water, dilute acids, alkaline, ozone and oxidizing chemicals. It has a negligible absorption rate, is not susceptible to swelling, and can withstand temperatures up to 100°C

Conclusion

It is important to realise that high heat affects tear strength. With 4.5 fasteners per square metre of roofing sheet, washers play a significant role in any roofing project. Realm recommends that consumers ensure that the washer they purchase complies with industry standards and supports the life and integrity of the roofing system. The right balance of hardness, tear strength and compression performance determine how well a cut washer assembles, compresses and resists the tearing effects of swarf, and keeps the screw sealed throughout its life on the roof.