Material innovation in the construction sector during 2025 reflects changing industry priorities. Factors such as emission reduction, long-term performance, cost control, and faster execution play a central role in material selection. As a result, attention has moved toward materials that are practical to deploy and compatible with current construction techniques.

The materials gaining traction this year fall into a limited number of categories based on how and where they are used.

1. Low-Carbon Cement and Binder Systems (LC³)

Limestone–Calcined Clay Cement (LC³) is a practical low-carbon cement option. It replaces part of Portland cement clinker with limestone and calcined clay, which are widely available.

Key characteristics:

- CO₂ emissions reduced by up to 40%

- Can be produced and used with standard concrete equipment

- Well suited for areas without reliable fly ash or slag supplies

Because of these advantages, LC³ is increasingly used in large infrastructure and residential construction projects.

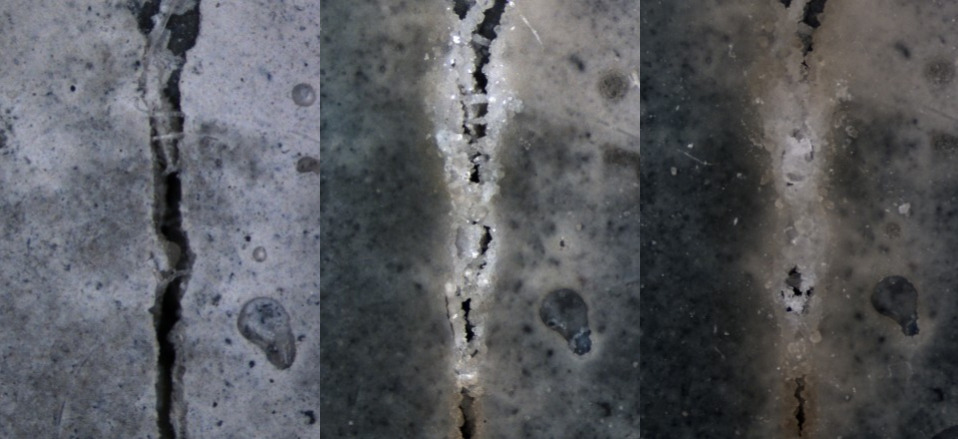

2. Self-Healing and Smart Concrete

Self-healing concrete helps prevent early cracking and improves durability. It contains bacteria or microcapsules that react when cracks form, sealing them in the presence of moisture or air.

Essential benefits:

- Longer service life of structures

- Reduced maintenance frequency

- Applicable to bridges, tunnels, foundations, and coastal structures

This material is selected mainly for durability improvement rather than cost reduction during construction.

3. High-Performance and Graphene-Enhanced Concrete

Graphene-enhanced concrete involves the use of nano-scale additives to improve the mechanical and durability performance of concrete.

Key performance aspects:

- Higher compressive strength at early ages

- Reduced permeability to water and chemicals

- Allows lower cement content for equivalent structural performance

It is used selectively in high-performance structures and critical infrastructure where strength and durability are priorities.

4. Mass Timber and Engineered Wood Systems (CLT)

Cross-laminated timber (CLT) is increasingly used in mid-rise residential and commercial buildings.

Main advantages:

- Reduces construction time with factory-made panels

- Lower embodied carbon compared to steel and concrete

- Predictable structural performance

CLT is commonly applied in hybrid structures combining timber with steel or concrete.

5. Bio-Based Construction Materials

Bio-based materials are increasingly applied in low-rise and residential construction.

Common examples:

- Hempcrete: Non-structural wall infill with thermal and moisture-regulating properties

- Mycelium-based materials: Mainly used for insulation and acoustic panels

Key benefits:

- Made from renewable or recycled resources

- Require relatively low energy to manufacture

- Improve indoor environmental quality

These materials are not replacements for structural concrete but serve complementary roles to enhance sustainability and building performance.

6. Smart, Transparent, and Adaptive Building Materials

Building envelope materials are evolving to improve energy efficiency and occupant comfort.

Trending materials include:

- Smart glass: Adjusts transparency to control heat and natural light

- Transparent wood: Provides better insulation than conventional glass

- Translucent concrete: Allows daylight to penetrate structural elements

These materials help reduce energy consumption while supporting functional and aesthetic design.

7. Recycled and Circular Construction Materials

Circular construction materials aim to reduce waste and lower the demand for raw materials.

Typical applications:

- Recycled plastic blocks and panels

- Compressed earth blocks made from local soil

- Concrete mixtures incorporating industrial by-products

These materials are commonly used in affordable housing and low-cost construction projects, providing sustainable and practical building solutions.

8. Digital and Industrialized Construction Materials

Materials designed for industrialized construction are a key trend in 2025.

Examples include:

- 3D-printable concrete and mortar mixes

- Prefabricated modular panels and structural elements

- Factory-cured components with controlled quality

Key outcomes:

- Faster construction timelines

- Reduced material waste

- Improved consistency and cost control

This category is especially useful for large-scale housing and infrastructure projects, supporting efficiency and quality on site.

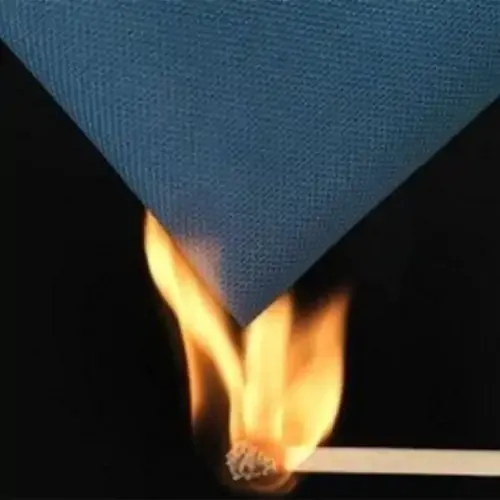

9. Fire-Resistant and High-Durability Protective Materials

Fire-resistant and high-durability materials are gaining attention in 2025 due to stricter safety regulations and climate-related risks.

This category includes:

- Advanced intumescent coatings that expand under heat to protect steel and concrete

- Fiber-reinforced cementitious boards for fire-rated walls and ceilings

- High-performance mineral composites resistant to fire, corrosion, and extreme weather

These materials enhance structural safety, particularly in high-rise buildings, tunnels, and industrial facilities.

Conclusion: Key Trends in 2025 Construction Materials

The most trending construction materials in 2025 are defined by scalability, performance, and practicality. Low-carbon cements and durable concrete systems lead due to their immediate impact, while engineered timber, bio-based materials, smart envelopes, circular solutions, and digital construction materials support efficiency and sustainability across different building types.

Together, these material types represent the current direction of the global construction industry.

Image Credit: ggba.swiss, discover.ukri.org, woodworks.org, tinyfindy.com, archdaily.com, resource.co, ie.edu, heaterk.com