Numerous existing bridges have reached the end of their lifespan and require replacement. The deteriorating condition of these bridges has generated a demand for innovative technologies capable of efficiently replacing them with modern and robust technologies. The imperative to enhance safety serves as a significant driver for the demand for bridge replacement technology. The progress achieved in materials science and construction techniques has unveiled new possibilities for bridge replacement. In response to this growing demand, the North Carolina Department of Transportation has announced the utilization of new technology to extend the lifespan of the replacement bridge linking Harkers Island and mainland Carteret County. They are using carbon-fiber-reinforced polymer, which aids in combating corrosion and ensures that the bridge under construction will outlast traditional bridges constructed with steel-reinforced materials.

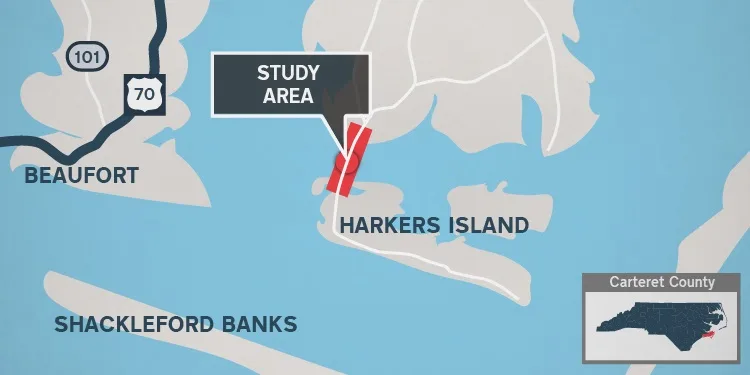

The North Carolina Department of Transportation (NCDOT) plans to replace Bridge No. 73 (Earl C. Davis Memorial), a swing-span bridge, and Bridge No. 96, the sole vehicular connection between the mainland and Harkers Island, with a fixed-span high-rise bridge The objective is to enhance the durability and lifespan of the bridge, given the highly corrosive marine environment of the Carolina coast.

About the bridge and why it needs replacement?

Located in Carteret County on the southern end of the Outer Banks, the region locally known as “Down East,” Harkers Island is a coastal gem popular amongst avid fishermen and tourists.

The island’s first bridge was a wooden bridge built in 1941 with a short service life of only 27 years. It was replaced in 1969 using concrete with steel reinforcement.

Previously replaced bridge reinforcement has been extremely vulnerable to deterioration due to the aggressive and corrosive environment of the coastal plain. The harsh saltwater causes steel-reinforced bridges to corrode at a more rapid rate, placing a hefty financial burden on NCDOT.

NCDOT resident engineer Brad McMannen said the salty environment poses a threat to traditional steel rebar.”As far as the bridge itself — the salty water is the issue and we need to prevent the salt water from eating away at the rebar,” he further stated

Traditional steel-reinforced bridges in the coastal area are prone to rapid deterioration due to the aggressive saltwater environment.

To combat this issue, NCDOT has opted for GFRP and CFRP reinforcement, which are non-metallic and resistant to corrosion caused by saltwater exposure.

Glass and carbon fiber reinforcement refers to the use of glass fibers and carbon fibers as reinforcing elements in composite materials. Both glass and carbon fibers are widely utilized for their exceptional strength, stiffness, and lightweight properties, making them ideal for reinforcing various materials.

GFRP and CFRP reinforcement for Harker’s Island Bridge

The Harkers Island Bridge will become the first fully-reinforced glass and carbon fiber bridge in the state. NCDOT expects the new design will better withstand the highly corrosive marine environment of the Carolina coast and extend the longevity of the bridge by decades. “Typically, new bridges are designed for a service life of around 75 to 80 years,” said Trey Carroll, NCDOT project engineer. “By using glass and carbon fiber-reinforcement, we can expect the new bridge to have an extended service life with more than a 100-year lifespan.”

Glass-fiber reinforcement cage to be fully encased in concrete

Advantages of GFRP and CFRP reinforcement for Harkers Island Bridge

1. Corrosion Resistance: GFRP and CFRP exhibit excellent corrosion resistance, making them ideal for bridges in coastal and marine environments. These materials do not rust or degrade when exposed to saltwater, ensuring the long-term durability of the bridge.

2. Enhanced Durability: Glass and fiber reinforcement significantly enhance the overall durability and lifespan of the bridge. These materials possess high tensile strength and stiffness, providing robust structural support and mitigating the effects of environmental factors.

3. Reduced Maintenance Needs: The corrosion-resistant properties of glass and fiber materials reduce the need for frequent maintenance and repairs. This not only extends the service life of the bridge but also minimizes maintenance costs and disruptions to traffic flow.

4. Lightweight Construction: Glass and fiber materials are lightweight compared to traditional steel reinforcement. This characteristic facilitates easier handling during construction and reduces the overall weight of the bridge, resulting in cost savings and improved structural efficiency.

By incorporating glass and fiber materials into the Harkers Island Bridge replacement, NCDOT aims to create a resilient and long-lasting bridge capable of withstanding the harsh coastal environment. This innovative approach showcases the commitment to utilizing advanced materials and technologies to enhance bridge performance and sustainability.

Collaboration for research on fiber-reinforced polymer (FRP) technology for bridge construction

The North Carolina Department of Transportation (NCDOT) collaborated with North Carolina State University to conduct extensive research on fiber-reinforced polymer (FRP) technology for bridge construction. The research project, initiated in 2013, focused on the use of non-corroding carbon fiber polymer in commonly used concrete bridge elements in North Carolina. The study confirmed that glass and carbon fiber are viable alternatives to traditional steel reinforcement.

When asked about the efficiency of using fiber-reinforced polymer in coastal bridge replacements, NCDOT research and development engineer Mustansir Kadibhai shed light on how the new design will eliminate the corrosion and durability problems faced by previous designs.

“Because fiber-reinforced materials are not metallic, they are not prone to corrosion — which addresses the durability concern of bridges located in coastal marine environments,” Kadibhai said.

Regarding safety concerns, Kadibhai assured that glass and carbon fiber technology is no longer considered new and is widely used in the transportation sector. He pointed out that bridges worldwide reinforced with these materials have remained in service for over 30 years. In the United States, numerous bridges are either in the design, construction, or operational phases, incorporating fiber-reinforced elements with successful field applications.

NCDOT has established codes and standards to ensure the safe design and construction of the bridge. These measures include comprehensive quality control and quality assurance procedures. The bridge’s design was undertaken by NCDOT structural engineers, adhering to the design guide specifications of the American Association of State Highway and Transportation Officials (AASHTO) for fiber-reinforced concrete bridges. The carbon and glass fiber-reinforcing materials were sourced from an accredited supplier affiliated with the Fiber Reinforced Polymer (FRP) Institute.

Glass and carbon fiber-reinforcing materials offer cost-effective alternatives for new infrastructure. They can also be used to repair existing infrastructure, extending their service life without the need for weight restrictions or bridge closures. Consequently, state and local agencies will save both money and time.

Significant advantages of bridge replacement for the community

The replacement of the Harkers Island Bridge will bring significant benefits to both the North Carolina Department of Transportation (NCDOT) and the local community. The ageing 50-year-old bridge have placed a financial burden on the department, but the new bridge will alleviate this strain.

Weight restrictions were imposed on the swing-span bridge (No. 73), impacting the local economy by limiting the size of freight trucks and commercial vehicles allowed to cross. Moreover, mechanical issues with the swing-span bridge often cause long delays or even closures, disrupting boat traffic.

The community, heavily involved in the commercial fishing industry, suffers from blocked navigational channels which affect their livelihood. The new bridge, with its increased vertical navigational clearance of 45 feet, will eliminate delays caused by bridge openings and closures for vehicles and vessels. This improvement will enhance accessibility to and from the island during emergencies and hurricane evacuations.

The ongoing construction of the new bridge, expected to be completed by fall 2025, represents a groundbreaking success for North Carolina. It sets the stage for the implementation of more advanced infrastructure technology throughout the state.

Pam Carriker, NCDOT Engineer II, emphasized the importance of working smarter, embracing innovation, and learning from experienced employees.

“We are going to have to learn to work smarter, be innovative, but we also need to be sure we’re capturing some of the wisdom from our seasoned employees — and make sure that we still understand why we are doing this — and continue being good stewards for the state of North Carolina,” he said.

Conclusion

The new Harkers Island Bridge will serve as a benchmark for future bridge designs to learn and adapt from. The project exemplifies NCDOT’s commitment to building resilient, efficient, and safer infrastructure that enhances the quality of life for North Carolina residents.

References; constructionequipmentguide.com,coastalreview.publicradioeast.org