Bengaluru roads have been in news for various reasons in recent times especially during the unprecedented rain that lasted this city a few months back. This invited a lot of comments and media attention regarding the condition of roads and the time taken for construction of new roads which in turn influenced the availability of actual road space for the public. In this time when the city administration is facing comments from the public, media and the courts. The City authorities BBMP in technical collaboration with UltraTech Cement has taken steps to implement a new technology that has been implemented on an experimental basis in Bengaluru city. This has been in the news for a couple of weeks.

Bengaluru is the place where many technologies for construction of road were experimented with, Plastic in roads (Bengaluru University campus), cement concrete overlay on bitumen road (popularly known as White Topping) gradually this white topping or cement overlay of bitumen road were done here. Concrete overlay has now become one of the seriously considered option for a sustainable and pothole free road.

Installing the barricades to avoid accidents. Road safety is taken care

Barricading is completed to start work

Worldwide concept of precast construction has been around for some time, it has been tried around in various parts of the world. Several methods have been tried out, just like any other precast construction the joining of various members has been a challenging issue. Hence the same concern remains even in the construction of roads with precast technology. The concern in precast road was to hold the various precast segments in place when rolling loads or the vehicle movement happened on the road for this engineer across the world did develop the connection details most of which is copyrighted by individuals or the organisations who developed this connection details.

A similar exercise has been tried out in India with its own connection details. By using a unique principle of precast post tensioning. UltraTech Cement as technical collaborator, the manufacturing ability of ARTO Precast Concrete, BBMP governing body of Bengaluru city has come out with a Pilot Project to construct a road with this technology called the Rapid Road.

Stacking the Precast panels at site before work commences

Sand cushion for placing the panels closely supervised by team members

This Pilot project road of 500 metres has been constructed on the old Madras Road near Indiranagar according to the engineers on site, the technical concept here was to ensure start existing road’s complete strength is utilised and an overlay of Precast Cement Concrete is provided to make the road last 40 to 50 years with least maintenance and very important to avoid potholes occurring. With some maintenance it would go further.

The important part of executing a precast road in the Indian Urban scenario is the fact how well we can map and make provisions for the services that could be constructed below the road surface over a period of time, how the widening of roads has happened thereby some utilities would have come to the middle of the carriageway. It is also required by the Engineers to anticipate probable service requirements, repairs etc., and will have to plan the system in a way, these problems could be addressed, including the future requirement of services, also provision for communication, electrical cables.

In this case we have been told that the provisions for future requirement of communication cables have been made on one side of the road where precast panels would not come, provisions for future passing of service lines across provision is made every 200m using RC-Hume pipes and most of this road didn’t have any service-related issues in the main carriage way.

System Used

The system worked out here consists of precast RCC slab 6M wide 1.5M in length and 0.175M thickness the joining of 2 panels has been designed with a male-female shear key and complemented with the post tensioning that happens in the road.

Construction Process

The deteriorated top surface of the old road has been removed and the corrections for weak spots corrections for cross drainage was done by using Dry Lean Concrete which is popularly known as DLC. The engineers at site informed that the cross-drainage slope was adequate in the existing road itself, the bottom level was formed to the design and construction detailing. A cushion of fine aggregates in this case crushed rock sand commercially known as m sand here was used 2A thickness of 25mm-50mm based on the undulations observed at site in the prepared surface This surface was made flat with a continuity to the next panel base.

The precast panels were then hoisted to the position. There are two types of precast panels used here, end panel which was provided with anchor points 4 post tension tendons and an intermediate panel which has male female shear connectors and a provision for the continuity of post tension tendons.

The alignment of carriage way and the continuity off the top level with smooth transition were maintained by levels & guidelines. Based on the practical application to site condition the post tensioning is done around to 22 to 30 panels.

This 500-metre road as in construction of rapid road technology took about 7 days of work including surface correction etc. The technical team of BBMP, UltraTech & ARTO were of the opinion that in larger projects where all precaution could be taken the work can progress much faster than this. Most delay is for the fact that the pilot project had to be sorted out as and when they came at site, the traffic restriction on an important road, lack of storage space for panels, the movement of panels from the factory had been done at night. The allied works of edge concrete gap filling formation of the shoulder completion of the manholes for both cables and sewer lines did continue for more time.

Moving the panels from the stacking points to be placed in position

Pre-cast Panels being placed on road for Proper alignment and levels

Joining of two consecutive panels

Post tensioning of tendon being made

Post tensioning tendons anchorage block

After Post tensioning the anchor points are grouted with non shrink cementitious grout

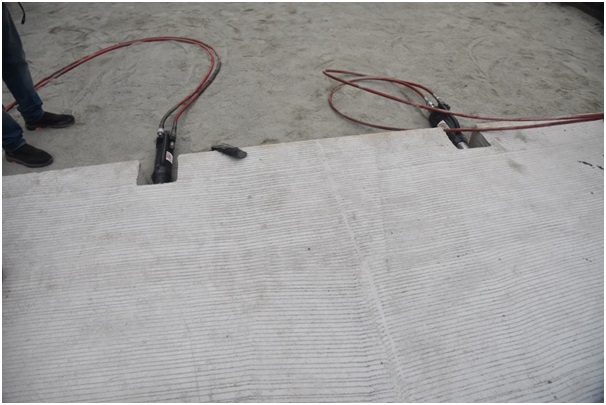

Cable insertion and post tension work. panels are placed with equal spacing to remove

The deteriorated top surface of the old road has been removed and the corrections for weak spots corrections for cross drainage was done by using Dry Lean Concrete which is popularly known as DLC. The engineers at site informed that the cross-drainage slope was adequate in the existing road itself, the bottom level was formed to the design and construction detailing. A cushion of fine aggregates in this case crushed rock sand commercially known as m sand here was used 2A thickness of 25mm-50mm based on the undulations observed at site in the prepared surface This surface was made flat with a continuity to the next panel base.

The precast panels were then hoisted to the position. There are two types of precast panels used here, end panel which was provided with anchor points 4 post tension tendons and an intermediate panel which has male female shear connectors and a provision for the continuity of post tension tendons.

The alignment of carriage way and the continuity off the top level with smooth transition were maintained by levels & guidelines. Based on the practical application to site condition the post tensioning is done around to 22 to 30 panels.

This 500-metre road as in construction of rapid road technology took about 7 days of work including surface correction etc.The technical team of BBMP, UltraTech & ARTO were of the opinion that in larger projects where all precaution could be taken the work can progress much faster than this. Most delay is for the fact that the pilot project had to be sorted out as and when they came at site, the traffic restriction on an important road, lack of storage space for panels, the movement of panels from the factory had been done at night. The allied works of edge concrete gap filling formation of the shoulder completion of the manholes for both cables and sewer lines did continue for more time.

The challenges that come are based on the local conditions of the road is that most of us observe in urban condition where the alignment of waste water line will be right in the middle of carriage way, care should be taken either bye realigning this sewer line or making the right kind of provision or right kind of construction detail at this junction however in Bengaluru city many of these issues have already been addressed by the city governing body BBMP by the concept called

Tender S.U.R.E where all aspects of services that could be conjugated with road construction will be addressed in one go with all technical expertise in respective fields the walk has been fairly successful.

What needs to be seen here in this case is how well the performance will bring confidence in the administration of Bengaluru city and in the technocrats who are behind these efforts.

The team from constrofacilitator.com did have a chat with the people at site who were supervising the job. We have been told that all aspects of construction are being documented to study the feasibility and adaptability of this technology in future projects both technically and administratively.

Thanks to Concroc Nagesh – concroc.in for an interaction and has given an overview.

Rapid Roads are ready to use

The citizens of this country especially the urban dwellers are looking forward to see this technology being implemented at more places and minimise the discomfort to common man traffic in key areas