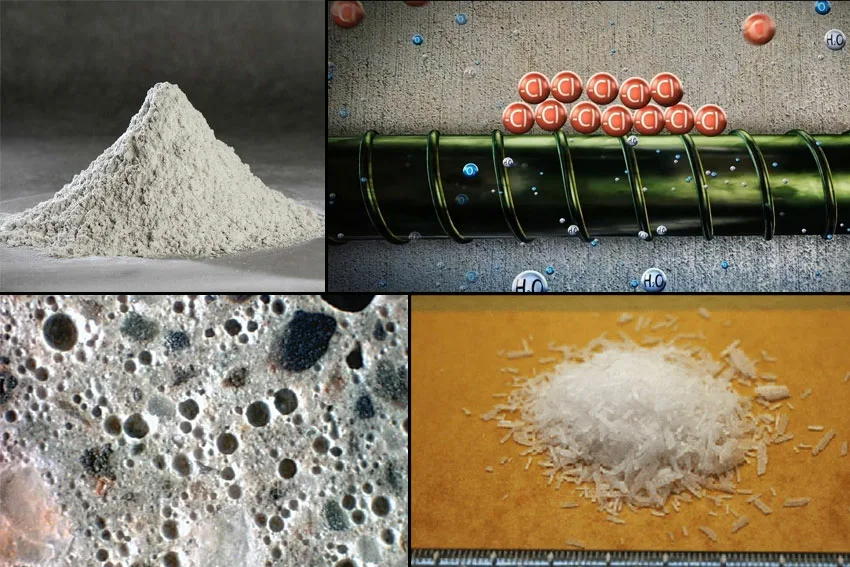

Admixtures are used in specialised concrete to enhance and modify its properties.These admixtures comprise a distinctive blend of chemical or mineral components that are incorporated into the concrete mixture to achieve specific and improved characteristics. These admixtures are carefully chosen and they are mixed in various proportions to influence the way concrete behaves at different stages, including when it’s mixed, placed, cured (allowed to set and strengthen), and during the hardening process (when it becomes more solid).

Advantages of admixtures in customising concrete properties

Admixtures play a pivotal role in customising the properties of specialised concrete to meet specific project requirements. Its advantages includes;

1. Enhanced Workability: Admixtures like plasticizers or superplasticizers improve the workability of concrete, making it easier to place, compact, and shape. This is especially useful for complex architectural designs or tight spaces.

2. Increased Strength:Admixtures such as high-range water reducers can help achieve higher compressive and flexural strength in concrete. This is important for projects where structural integrity and load-bearing capacity are crucial.

3. Durability Improvement: Admixtures like air-entraining agents create microscopic air bubbles in the concrete, enhancing its resistance to freeze-thaw cycles and reducing the risk of cracking and deterioration.

4. Reduced Permeability: Admixtures like water-reducing agents and pozzolanic materials reduce the permeability of concrete, making it less susceptible to water penetration, chemical attacks, and corrosion of embedded steel.

5. Controlled Setting Time: Retarding or accelerating admixtures can be used to adjust the setting time of concrete. This is advantageous in situations where you need more time for placement or rapid construction schedules.

6. Work in Challenging Environments: Admixtures can help tailor concrete for extreme conditions, such as high temperatures or aggressive chemical environments, ensuring the longevity and performance of structures.

7. Environmental Benefits: Amixtures like supplementary cementitious materials, can help reduce the carbon footprint of concrete by replacing a portion of cement. This contributes to sustainable construction practices.

8. Quality Control: Admixtures facilitate consistent concrete production by reducing variations in the mix, leading to more predictable results in terms of strength, durability, and overall performance.

Different types of admixture for specialised concrete

High-Strength Concrete (HSC) Admixtures:

1.Superplasticizers: These chemical admixtures are used in high-strength concrete to enhance its properties. They work by improving the workability of the concrete mixture without increasing the water content. These admixtures allow for better flow and ease of placement of high-strength concrete, making it easier to work with during construction.They also enable a reduction in the water-cement ratio, which is essential for achieving high compressive strength in concrete. This results in denser, stronger, and more durable concrete.

2.Accelerators: These admixtures are used in high-strength concrete for specific purposes, especially when rapid strength development is required. The admixtures speed up the setting and early strength development of concrete. This is valuable in cold weather conditions or when there’s a need for a faster construction pace. They also enable high-strength concrete to achieve its required strength levels earlier, allowing for quicker formwork removal and project progression.

3. Silica Fume: These admixtures are added to high-strength concrete to enhance its performance. It improves the compressive strength and durability of high-strength concrete. It fills the spaces between cement particles, leading to a denser matrix.The increased density and reduced porosity resulting from silica fume incorporation enhance resistance to chemical attack, abrasion, and permeability. It can also mitigate shrinkage and cracking tendencies, which are critical concerns in high-strength concrete due to its reduced water content.

Self-Consolidating Concrete (SCC) Admixtures:

1. Viscosity-Modifying Admixture: These types of admixtures are used in concrete to alter its viscosity, or resistance to flow, without significantly affecting the mix’s water content. These admixtures are particularly useful in creating self-consolidating concrete (SCC) that can flow and fill intricate forms without the need for vibration, making it suitable for complex and congested reinforcement arrangements.

2. High-Range Water Reducers: These types of admixtures added to concrete mixes to significantly reduce the amount of water required while maintaining or improving workability. These admixtures maintain the desired flow properties of SCC while reducing water content, leading to enhanced strength and durability.

Colored Concrete Admixtures:

1. Retarders: These admixtures are used in coloured concrete to slow down the setting time. This is essential for achieving consistent colour and providing ample time for proper placement and finishing.

2. Integral Color Admixtures: These admixtures are mixed directly into the concrete mix, these provide uniform colour throughout the entire concrete element, eliminating the need for additional surface coatings.

High-Performance Concrete (HPC) Admixtures:

1. Pozzolanic Admixtures: These admixtures include materials like fly ash, silica fume, and slag that react with calcium hydroxide in the presence of water and form additional cementitious compounds. This enhances the strength, durability, and chemical resistance of the concrete. Pozzolanic admixtures can reduce the heat of hydration and the risk of alkali-silica reaction.

2. Corrosion Inhibitors: These admixtures are used to protect the reinforcing steel bars within concrete from corrosion caused by exposure to aggressive environmental conditions or de-icing salts. They create a protective layer on the surface of the steel, preventing water and aggressive chemicals from reaching it.

3. Air-Entraining Admixtures:These admixtures introduce microscopic air bubbles into the concrete mix. These bubbles improve freeze-thaw resistance by providing space for water to expand when it freezes, reducing the potential for cracking and damage.

4. Shrinkage-Reducing Admixtures: These admixtures minimise drying shrinkage cracks by controlling the shrinkage of concrete. They are used for modifying the properties of the cement paste within the concrete matrix. They reduce capillary tension and restrain the volume change caused by moisture loss, thereby curbing the potential for cracking. This is particularly important in high-performance concrete applications, such as high-rise buildings, bridges, and infrastructure projects.

The selection of admixtures relies on the project’s needs, the prevailing environmental conditions, and the intended properties of the concrete. It is of paramount importance to carefully choose and proportion admixtures to attain the desired performance and durability of specialised concrete mixes. Seeking guidance from a concrete specialist or engineer is imperative for identifying the most suitable admixtures for a particular application.

In this article, we have discussed various types of admixtures used in high-strength concrete, self-consolidating concrete, coloured concrete, and high-performance concrete. In an upcoming article we will delve into additional categories of admixtures used in specialised concrete.