Flexible asphalt is one of the most widely used types of pavement. This surface coating has 3 main layers which are:

- Surface course

- Base course

Sub-base course

and three sub-layers that help keep the main layers from sliding:

- Tack coat

- Binder course

- Prime coat

Sometimes in order to protect asphalt from damage or erosion, protective asphalt is applied.

In this article, the main and sub-layers are introduced from the lowest to the highest.

Keep reading this article to get more information about them.

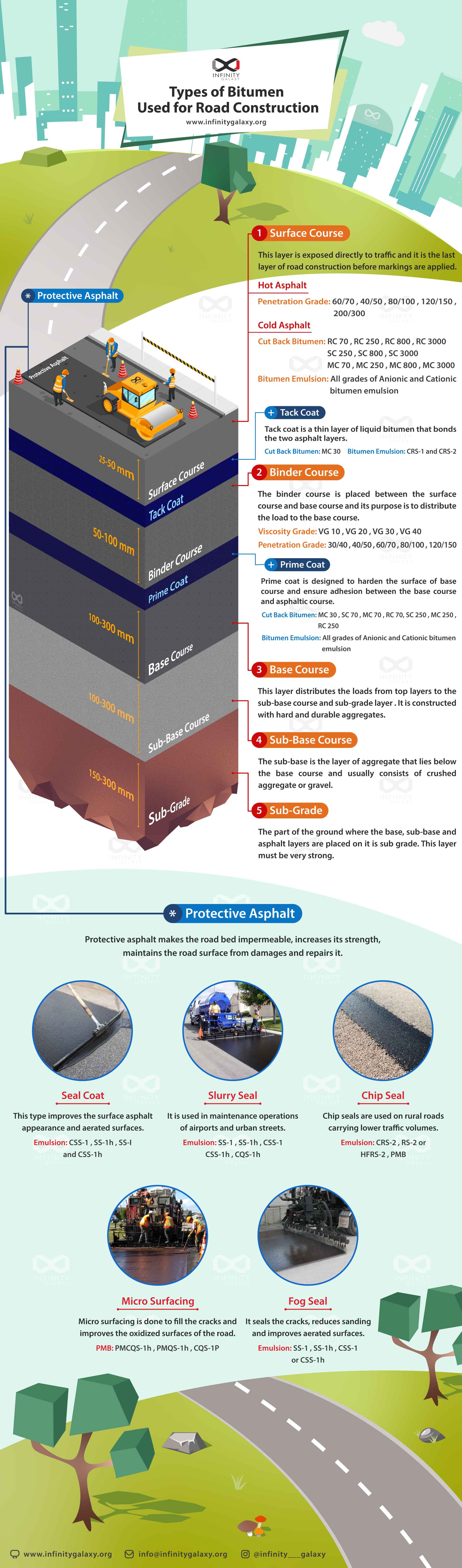

Moreover, the attached infographic of Infinity Galaxy company takes an overall look at this topic and the types and grades of bitumen that can be used in the layers of flexible pavement.

1- Surface Course

The surface course is the upper layer of the road. It covers all layers of the road at the end of the construction.

The surface course must withstand the traffic load directly into it and weather conditions. As a result, it is necessary to use high-quality aggregates with sufficient quality bitumen.

Bitumen should be selected according to the weather conditions and the amount of regional traffic. Also, aggregates should have high strength.

This layer of asphalt undergoes temporary or permanent deformation with the changes of the underlying layers. As a result, particle correlation is very important.

4- Tack Coat

Tack coat is a very thin bitumen layer. It is sprayed on the binder coat before the surface course is poured on the surface.

Tack coat applications are to maintain the binder coat and act as a good stick between binder and surface courses.

Usually, the bitumen types of this stage are emulsion grades CRS-1 and CRS-2 also, cutback mc30.

5- Binder Course

Binder course should distribute the applied traffic load of the surface course to the base course. Usually, binder course does not have high quality aggregates and it contains fewer amounts of bitumen.

If there is no budget limit, it can be possible that there is no separate layer called binder course and instead the thickness of the surface layer is deeper.

6- Prime Coat

After the base course, a layer of liquid bitumen is sprayed on its surface, which is known as a prime coat.

This layer is applied to increase the adhesion between the base course and the binder course.

The liquid bitumen penetrates into the aggregates of the base course, and as a result, the asphalt of the upper layer adheres better to the base oil.

2- Base Course

The base course layer plays an important role to transfer the load from all the upper layers to the lower layers.

The base course should be composed of hard and durable materials. It can be composed of mountain gravel, riverbed rocks, or macadam.

Macadam is a combination of coarse aggregates and fine particles of stone.

3- Sub-base Course

The sub-base course is usually the first layer that is placed on the prepared bed pavement. It is made up of large granular aggregates. It does not need to use a sub-base if the field ground (Soil Subgrade) is very hard.

It is necessary to use Sub-base when the soil subgrade is unable to withstand the weight of the upper layers and the pressure of traffic loads.

Subgrade

The subgrade is the part of the ground. There are three layers covering it: the base course, the sub-base course, and the asphalt.

The subgrade must be very strong and able to tolerate the loads transferred from the pavement layers.

7- Protective Asphalt

Protective asphalt is a low-price pavement used on the surface of asphalt for preventing or repairing flexible asphalt.

They are made of liquid bitumen like cutback and emulsion.

There exist several types of protective asphalts including

- Seal Coat

- Slurry Seal

- Chip Seal

- Micro Surfacing

- Fog Seal