Dry-shake surface hardener is a cementitious product containing hard aggregates (quartz, metal, or corundum), admixtures, pigments and polypropylene fibers A dry-shake is sprinkled evenly over a fresh concrete floor while it is plastic, and when the dry-shake is power-troweled, it bonds monolithically to the base concrete. It is applied on the fresh concrete surface by hand or machinery and then power floated and troweled. They decrease typical plain concrete negative properties like dusting and liquid absorption by improving the abrasion resistance and reducing surface permeability. The selection of right dry shake floor hardeners is important for your industrial flooring facilities. Concria Optimal Slab™ Industrial New generation dry-shake hardener floor is just the correct solution for your industrial flooring facilities. Concria Optimal Slab™ Industrial dry-shake hardener is made from uniquely hard and coarse aggregates, modified Portland cement, polypropylene microfibers, and additives.

Concria Optimal Slab™ industrial dry shake hardener together with Trowel Hard nano silica significantly reduces the typical problems of dry shake floors, such as delamination, plastic cracking, and wear resistance. The product contains polypropylene fiber, which improves workability and significantly improves adhesion. Concria dry shakes are available in all RAL colors and hardness classes (Böhme A1.5 – A6). Concria dry shakes contain polypropylene fiber, which improves workability and significantly improves adhesion. Concria dry shakes are available in all RAL colors and hardness classes (Böhme A1.5 – A6).

If you want to meet the abrasion resistance requirement set for the dry shake, then the dry shake must be installed in two layers of at least 6kg/m2. Below is a picture that shows the difference in layer thickness. 3kg/m2 practically does not leave a wear-resistant dry shake layer at all, because the dry shake mixes with the substrate when troweling. 6kg/m2 installed in two layers also covers all the metal fibers but also guarantees a durable and dense dry shake surface.

An analysis of Lithium vs Sodium vs Concria Nano silica densifier test

All silicates react with Calcium hydroxide and claim to make concrete floor dust-free and harder, but which silicate reacts fastest?

Concria Polish Hard XL- High solid, fast react Nano silica densifier for concrete, dry shake, and low-lime overlays!

The goal of all concrete densifiers (Lithium, Sodium, Potassium, and Colloidal silica) is to deliver a reactive form of silica down into the microscopic pore system of the cement paste. All densifiers have the “same” chemistry varying only by the alkali used for solubility of the SiO2 (Silica). The differences are in the particle form and size of the silica and how the silica is made to stay in the liquid.

Concria Polish Hard XL delivers virtually pure silica in nanoparticles small enough to penetrate the pore structure. The nano-sized silica particles have a lot higher proportion of reactive surface than silicates, so they react very rapidly and efficiently.

In the pores, Polish Hard XL creates a new CSH that bonds to the existing CSH. Nano silica also bonds directly to other silica, including itself. When applied to concrete, it reacts, bonds, and then uses that bonded silica as a platform for additional bonding. Other Silicate densifiers do not do this. Reactive Polish Hard XL even bonds to and hardens decorative cementitious overlays that are low-lime, traditional silicate densifiers will not do this.

Sodium and potassium densifiers are compounds of silicon and a high proportion of mineral salts. (Sodium silicate molecules, for example, are 38 percent sodium by weight and only 62 percent silica. When Sodium silicate densifiers release silica to form CSH, they leave behind the mineral salts. This is why sodium silicate and potassium silicate must be scrubbed off, to prevent the residual salts from forming hard, discoloring deposits. Polish Hard XL is 99.5 percent pure silica, so residual deposits are not an issue, This allows for easier, faster application and time savings.

Concria Polish Hard XL not just reacts much faster than other densifiers, but it also makes the concrete surface more durable and abrasion-resistant than silicate densifiers.

Check the video link for a better understanding

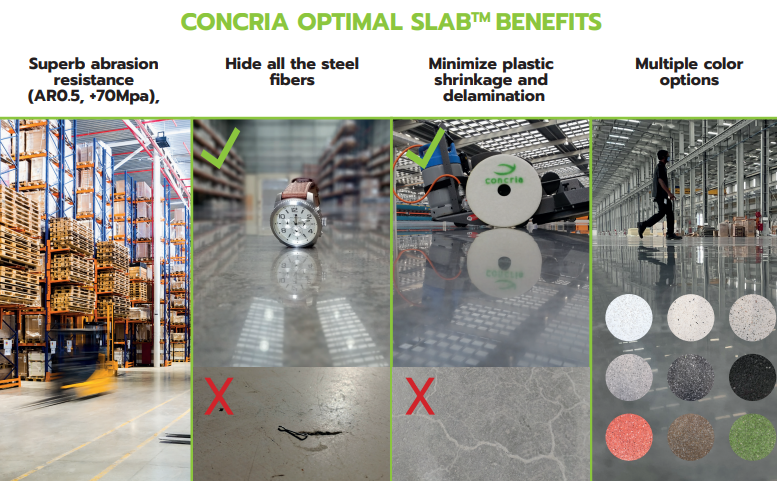

Concria OPTIMAL SLAB™ Industrial New generation dry-shake hardener floor advantages

- Light Reflective Values for different concrete surfaces

- Patented Concria Optimal Slab™ Industrial floors hide all metal and plastic fibers

- Dense, smooth, and seamless surface

- Surface finishing and colour options

- The risk of plastic shrinkage is significantly reduced

- Better adhesion to the base concrete

- Completely dust-free surface

- A smoother and denser surface makes it easier to clean

- Longer service life and almost maintenance-free

- Reliable even in difficult casting conditions

Concria OPTIMAL SLAB™ Industrial New generation dry-shake hardener floor applications;

- Industrial and parking garages

- Logistics and data centres

- Waste management facilities

- Terminals

Concria OPTIMAL SLAB™ industrial dry shake hardeners provide an economical and durable finish for industrial concrete floors. As with all construction products, proper installation is critical to overall performance. A perfect mix of Conria’s products and the right contractor will result in a concrete floor finish that will support the operations and long-term, easily maintained, and safe work surface.

About Concria Floor Solutions Private Limited

Concria Floor Solutions Private Limited is one of the leading manufacturers of a wide range of specialized concrete flooring products. The company’s range consists of polishable dry shakes, finishing aid and hardener, a superhydrophobic penetrating sealer, Cementitious Screeds, and Polishing tools The product range is designed to withstand harsh conditions and cater to a variety of needs for commercial and industrial applications.

If you are facing problems such as surface delamination, plastic shrinkage, and non-uniform colour, visit- https://concria.com/industrial/