If you have concrete that starts to reveal its age, you have two alternatives: demolish the old surface and drain it, prepare the foundation and pour out a fresh slab. Or restore the slab to a new and fresh look, use a resurfacing technique. Concrete resurfacing is a method of restoring the durability and appearance of dilapidated concrete.

Concrete resurfacing is used if the concrete has superficial cracking, discolouration, chipping and spalling. A concrete resurfacer is a special cement product that mixes regular Portland cement, sand, polymer modifiers and other additives to provide compensation for adhesion and shrinkage. It is applied in very thin coats that provides robust, wear-resistant surface that is built to withstand heavy traffic.

Why does concrete need resurfacing?

- To improve aesthetics and ambience

- To remove undulations in the concrete that is to receive carpet, vinyl, wooden or other polymeric flooring

- To overcome defects in existing concrete floor

- To enhance resistance to penetration of oil, grease, water, chemicals etc

- To reduce/eliminate dust generation

- To improve abrasion resistance

- To facilitate material movement and reduce maintenance cost

- To enhance safety to workmen

Why Concrete Floors need resurfacing?

- Although concrete provides most of the industrial flooring substrate, it does not serve as a good long term wear surface due to the nature of the product.

- Continuous traffic will cause concrete to dust and spall, which can cause severe damage to sensitive equipment as well as human health hazards.

- Exposure to impact, vibration and heavy loads will result in cracks and potholes.

- Moisture and chemicals will penetrate the porous surface and can cause a variety of physical and chemical changes to the concrete itself. In extreme conditions these chemicals may eventually pass through the concrete to contaminate the ground or aquifer system.

- In addition, clean industrial environments, such as food, beverage and pharmaceutical applications, require finished concrete to seal the surface preventing contamination from the substrate.

What are the Common Defects in Concrete Floors

- Concrete spalling

- Chemical Spillage

- Salt finish concrete

- Discoloration

- Scaling

- Undulated concrete

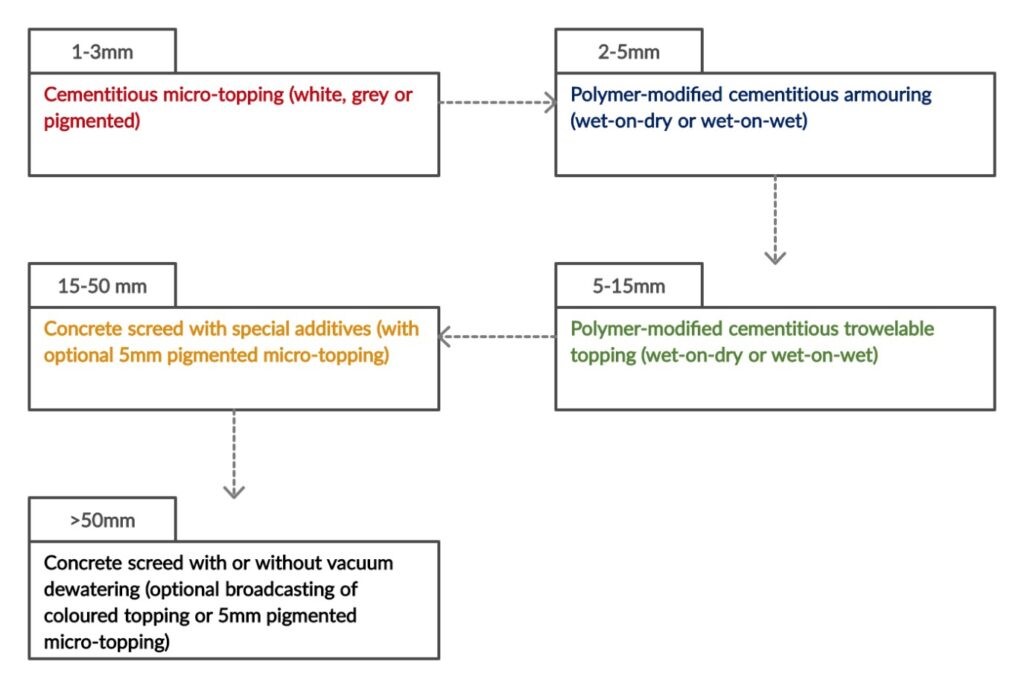

Guidelines for Protecting the Concrete Based on Thickness

A good concrete resurfacing system is designed to bond to the old concrete substrate at the molecular level, creating a seamless surface finish in natural earth tone colours of your choice, without the hassle of pouring concrete and the headaches that go with it.

Recommended Products:

Cementitious systems:

- 1-3mm : Neocoat UTM

- 2-5 mm : Neoflor 3010

- 5-15mm : Neoflor 3010 / Neoflor D’Cor 100

- 15-50 mm: Neoscreed additive (to be used with Concrete screed)

- >50mm : Coloured Ultra stamp powder

Specialty floorings:

- Aquacrete HDCC

- Neocrete HDF

Specialty floorings for special applications

- Water-borne epoxy cement composite flooring (with or without polishing)

- Water-borne polyurethane cement composite flooring

The above floorings are required when the following properties are desired:

- Where exceptional abrasion and impact strength are required

- Hot water/steam wash is required

- Specified chemical resistance

- As moisture barrier system

With so many options, the best choice out there for revitalising worn-out concrete seems to be concrete resurfacing. Remember, however, that if your concrete driveway has substantial damage from freezing or thawing, is heaving, or has sub – soil issues, you can end up ripping up the new surface and pouring concrete all over again, rebuilding the whole driveway essentially. But it’s best to check to see if this choice is right for you with the concrete pros.

Authored by- Mr.B.M.Nagarajan, Director, Neocrete India

For more details, visit- https://www.neocrete.co.in/