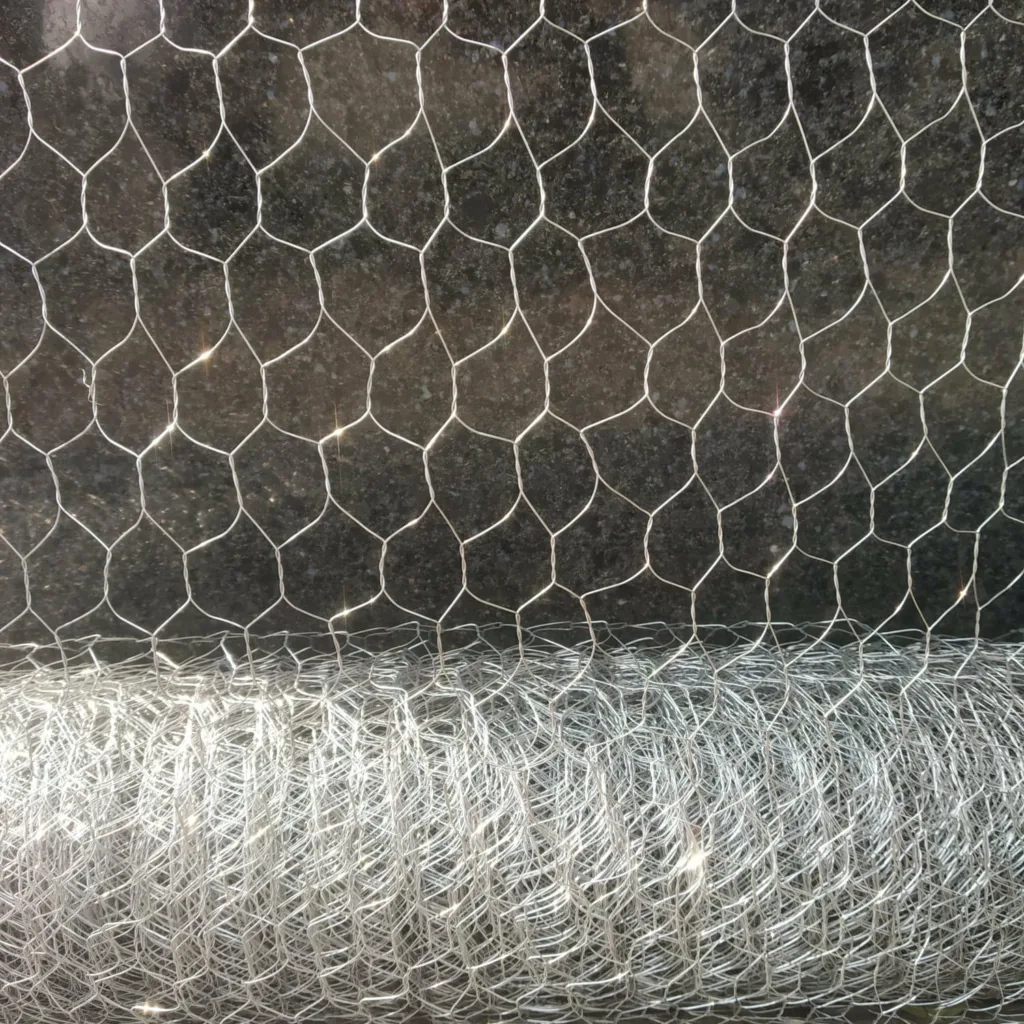

Chicken wire mesh is a flexible metal mesh commonly used in construction for reinforcing plaster. It typically comprises of thin, pliable wire arranged in a hexagonal pattern, offering adaptability to different surfaces, whether flat or irregular. This mesh’s hexagonal design facilitates easy installation, conforming seamlessly to diverse substrates. By integrating this mesh prior to plaster application, surfaces benefit from enhanced stability and durability, particularly in regions susceptible to movement or stress.

Different uses of chicken wire mesh for plastering

1. Walls: Chicken wire mesh is often installed on walls before plastering to provide structural support and prevent cracking.

2. Ceilings: When plastering ceilings, chicken wire mesh helps distribute the weight of the plaster evenly and minimizes the risk of sagging or cracking.

3. Architectural Elements : It can be used on architectural elements such as arches, columns, and decorative elements to reinforce the plaster and maintain their integrity over time.

4. Exterior Surfaces: In outdoor applications, chicken wire mesh is employed to reinforce plaster on surfaces like stuccoed walls, ensuring durability and resistance to weathering.

5. Repair Work: When repairing damaged plaster, chicken wire mesh is often utilized to provide additional strength and support to the patched area, preventing future cracking or crumbling.

Advantages of chicken wire mesh for plastering

- Provides structural support, minimizing cracks.

- Conforms to various surfaces for even coverage.

- Cost-effective reinforcement solution.

- Suitable for indoor and outdoor use.

- Easy to install, streamlining the plastering process.

- Enhances performance and durability of plaster.

- Extends lifespan by preventing damage.

- Resistant to corrosion, ensuring longevity in different environments.

- Offers added insulation and soundproofing properties when used with plaster.

- Allows for better adhesion of plaster, resulting in a smoother finish.

- Can be easily shaped and cut to fit specific project requirements.

- Compatible with different types of plaster, including traditional and modern formulations.

- Enhances fire resistance when combined with fire-resistant plaster.

- Provides added security by reinforcing walls and ceilings.

- Facilitates the creation of intricate decorative designs in plasterwork.

- Offers environmental benefits as a recyclable material.

- Can be used as a temporary fencing solution in addition to its plastering applications.

- Helps prevent shrinkage and warping of plaster over time.

Types of chicken wire mesh used for plastering

Light Expanded Metal Mesh: Light expanded metal mesh is a versatile material formed by stretching a metal sheet, creating a diamond-shaped pattern. Its ribbed structure ensures excellent adhesion to surfaces, making it perfect for supporting plaster and stucco. This mesh offers durability, strength, and lightness, making it suitable for interior decoration and reinforcement.

Linked Chain Wire Mesh: Linked chain mesh, also known as mini or micro chain wire fences, is made of materials like low carbon steel or galvanized wire. Lightweight and designed to prevent crack formation on walls due to temperature changes, it’s often used in areas prone to high vibration impacts, providing additional reinforcement before plaster application.

Fiberglass Wire Mesh: Fiberglass mesh is a specialized type of chicken wire mesh known for its non-flammable properties and high strength. Resistant to alkalis, stretching, and tearing, fiberglass mesh is a popular choice for plastering applications. It protects surfaces from crack formation and is relatively easy to apply. Fiberglass mesh finds extensive use in plaster facades, internal walls, and ceilings due to its durability and versatility.

Plastic Wire Mesh: Plastic mesh is an alternative to traditional metal mesh, offering similar benefits with some additional advantages. Suitable for both interior and exterior surfaces, plastic mesh provides resistance against crack formation and increases the mechanical strength of structures. Its lightweight and easy-to-handle nature make it convenient for various applications, including plasterwork, paintwork, floor pouring, and facade protection. Plastic mesh comes in square or rectangular gap shapes and is often used for longer spans of walls due to its versatility and durability.

Galvanized Chicken Wire Mesh: Galvanized chicken wire mesh is made from steel wire coated with zinc to protect against corrosion and rust. Its durability and affordability make it a popular choice for various applications, including poultry fencing, garden protection etc. The galvanized coating ensures longevity, even when exposed to outdoor elements, making it suitable for both indoor and outdoor use.

Vinyl-Coated Chicken Wire Mesh: Vinyl-coated chicken wire mesh offers the same benefits as galvanized wire but with an additional layer of protection. The vinyl coating provides extra resistance against corrosion, rust, and weathering, making it ideal for outdoor applications where prolonged exposure to moisture is expected. This type of chicken wire is commonly used for garden fencing, animal enclosures, and other outdoor projects where durability is paramount.

Plastic Chicken Wire Mesh: Plastic chicken wire mesh is lightweight, flexible, and rust-proof, making it an excellent alternative to traditional metal wire. It’s commonly used for temporary fencing and garden protection due to its ease of use and versatility. While not as durable as metal wire, plastic chicken wire is suitable for applications where weight and flexibility are important considerations.

Hexagonal Chicken Wire Mesh: Hexagonal chicken wire mesh is characterized by its hexagonal-shaped openings, providing versatility for a wide range of applications. It’s commonly used for poultry fencing, garden protection etc. due to its lightweight and flexible nature. Hexagonal chicken wire is available in various gauges and mesh sizes to suit different needs, making it a popular choice among homeowners and gardeners.

Welded Wire Mesh: Welded wire mesh is constructed by welding steel wires together at intersections, resulting in a stronger and more rigid structure compared to traditional chicken wire. It’s suitable for heavy-duty applications such as animal cages, fencing, and construction projects where strength and durability are essential. Welded wire mesh offers superior security and stability, making it a preferred choice for enclosing larger animals or securing property boundaries.

Stainless Steel Chicken Wire Mesh: Stainless steel chicken wire mesh is highly durable and corrosion-resistant, making it ideal for applications where hygiene and longevity are crucial. It’s commonly used in food processing facilities, marine environments, and industrial settings where exposure to moisture and harsh chemicals is expected. Stainless steel chicken wire offers superior strength and durability compared to other materials, ensuring reliable performance in demanding conditions.

Heavy-Duty Chicken Wire Mesh: Heavy-duty chicken wire mesh is designed with thicker wires and smaller mesh openings to provide enhanced strength and security. It’s commonly used for predator-proof fencing, enclosing larger animals, and protecting valuable crops from wildlife damage. Heavy-duty chicken wire offers peace of mind for farmers, ranchers, and homeowners seeking reliable protection against pests and predators.

Lightweight Chicken Wire Mesh: Lightweight chicken wire mesh is made from thinner wires and features larger openings, offering flexibility and ease of manipulation for various projects. It’s commonly used for temporary fencing and small animal enclosures due to its lightweight and malleable nature.

Application method of using chicken wire mesh for plastering

1. Surface Preparation: Ensure that the surface to be plastered is clean, dry, and free from dust, debris, and any loose materials. Repair any cracks or damage as needed.

2. Cutting and Securing the Mesh: Cut the chicken wire mesh to the desired size using wire cutters. Affix the mesh to the surface using staples, nails, or a suitable adhesive. Ensure that the mesh is securely attached and lies flat against the surface without any gaps or wrinkles.

3. Overlap and Secure Seams: If multiple pieces of mesh are required to cover the entire surface, overlap the edges of adjacent pieces by at least a few inches to ensure a continuous and seamless coverage. Secure the overlapping seams with additional staples or wire twists to prevent movement during plastering.

4. Mixing Plaster: Prepare the plaster mixture according to the manufacturer’s instructions, ensuring the correct ratio of plaster to water and thorough mixing to achieve a smooth consistency.

5. Applying Plaster: Using a trowel or plastering tool, apply the plaster evenly over the chicken wire mesh, starting from the bottom and working your way up. Press the plaster firmly into the mesh to ensure good adhesion and coverage. Work in small sections to prevent the plaster from drying out too quickly.

6. Smoothing and Finishing: Once the plaster is applied, use the trowel to smooth and level the surface, removing any excess plaster and creating a uniform finish. Allow the plaster to dry completely according to the manufacturer’s recommended drying time.

7. Optional Additional Coats: Depending on the desired thickness and finish, additional coats of plaster may be applied once the initial coat has dried. Allow each coat to dry thoroughly before applying the next one.

8. Final Finishing: After the plaster has fully dried, sand the surface lightly to remove any imperfections and achieve a smooth finish. The surface is now ready for painting, wallpapering, or other finishing touches as desired.

Conclusion

Chicken wire mesh offers a reliable and cost-effective solution for plastering needs. Its flexibility, strength, and adaptability make it an excellent choice for reinforcing plaster and providing structural support in construction projects. With its ability to conform to different surfaces and withstand various conditions, it proves to be a valuable asset for creating durable and stable structures both indoors and outdoors. Incorporating chicken wire mesh into plastering projects can lead to enhanced longevity and resilience, ensuring the longevity of the finished project.