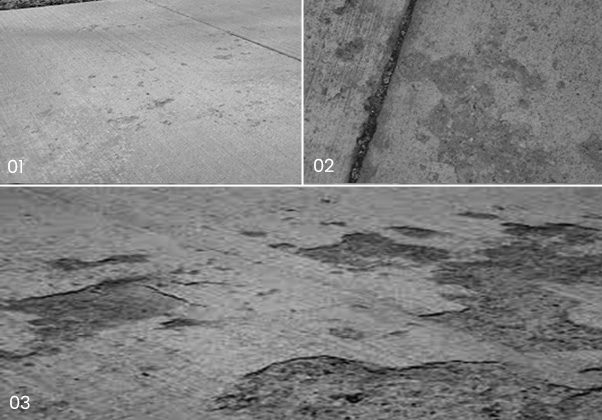

Concrete scaling is the flaking or peeling of a hardened concrete surface. It is caused due to hydraulic pressures caused by the expansion of water from repeated freeze-thaw cycles within the concrete. The expansive forces caused by the formation of ice and deicing chemicals increase both the saturation of the concrete and the number of freeze-thaw cycles causing light, medium to very severe distress in concrete. It might start with small patches, which can merge to create exposed large areas, leading to aggregate popping out and spalling.

Causes of concrete scaling

- The use of non-air-entrained or less entrained air agents in concrete mix

- Use of inadequate amount of calcium or sodium chloride deicing salt with lower strength concrete

- Using concrete with low strength or high water cementitious ratio

- Finishing work executed with bleed water at the top of the surface

- Improper finishing of concrete slab

- Early or accelerated drying of the exposed concrete surface

- Lack of inadequate curing and protection

- Exposure of new concrete to freezing and thawing before it has been adequately cured

- Exposure to aggressive/corrosive salts and fertilizers

- Inadequate use of supplementary cementitious materials

- Choosing improper curing methods

- The use of deicing chemicals in new concrete increases the amount of scaling

- Accelerated drying of concrete

Prevention Measures for concrete scaling

- Use a proper concrete mix with durable and well-graded aggregates and a low water-cementitious ratio

- Concrete exposed to freezing and thawing cycles must be air-entrained

- Do not perform any finishing operation with water present on the surface and also initial screeding should be done followed by bull-floating

- Properly slope the concrete surface to drain water away from the slab

- Provide proper curing by using a liquid membrane curing compound or by covering the surface of the newly placed slab with wet burlap

- Apply a commercially available silane or siloxane-based breathable, penetrating concrete sealer specifically designed for concrete slabs

- Do not use a jitterbug or vibrating screed with high slump concrete

- Prevent the addition of water when concrete is troweled or floated

- Curing should be done properly and it should be done at least for 7 days and done according to the no of days required

- Provide curing using a liquid membrane compound which increases the strength of the concrete

- Avoid using salts such as calcium, magnesium, or sodium chloride on newly placed concrete

- Finishing should be done properly

- Protect newly placed concrete from severe environmental conditions

- Make the concrete dry before the sealer application

Concrete scaling repair methods;

ACI classifies scaling as light (loss of surface mortar without exposure of coarse aggregate), medium (loss of surface 0.2 to 0.4 in. in-depth and exposure of coarse aggregate), severe (loss of surface 0.2 to 0.4 in. in-depth with some loss of mortar surrounding aggregate particles 0.4 to 0.8 in. in-depth) and very severe (loss of coarse aggregate particles as well as surface mortar, generally to a depth greater than 0.8 in.). There are different methods of repair depending upon the scale of deterioration.

Light and medium concrete scaling repair;

- The surface which is to be repaired should be free from dirt, oil, or paint

- Use a hammer and chisel, shot-blasting or jackhammer to remove all weak or unsound material.

- Apply sealer to create a moisture barrier for preventing the water to penetrate the concrete

Severe concrete scaling repair;

For a severe case of concrete scale, you need resurfacing with thin bonded toppings. There is a need for the right placing and finishing to accomplish this.

- Loose concrete should be removed and cleaned well

- Apply a thin layer of cement paste before the installation of concrete resurfacing material

- The surface should be kept damp before placing of resurfacing material

- Place proper concrete type to resurface the damaged area

- You can choose Latex-modified concrete- Portland cement resurfacing/ Latex modified concrete resurfacing/ Polymer-modified cementitious based repair mortar as per project need

- Thoroughly brush a portion of mortar into the substrate and complete the pour to bring up the concrete to the desired level

- Little pressure should be given for efficient troweling

- Sealer should be used for covering all the construction joints

- Curing for 5 days depending on the actual project size requirement

Conclusion

Discussed above are different causes of concrete scale, its prevention measures and repair methods. The concrete scaling not only degrades the concrete but impacts its durability. So, the scaling should be cured initially by an appropriate technique.

Analysis of Concrete scaling

Prevention Measures for concrete scaling

Concrete scaling repair methods

Light and medium concrete scaling repair

Severe concrete scaling repair