India is experiencing a surge in demand for diverse building materials driven by rapid urbanisation and the demand for residential and commercial projects. Selecting the right manufacturer is important to address this demand efficiently. Manufacturers with advanced technology, sustainable practices, and a reliable supply chain can meet the evolving needs of the market while ensuring quality and cost-effectiveness. Aparna Enterprises Ltd [AEL] is one such company manufacturing a wide spectrum of building-material products, such as RMC (ready-mix concrete), uPVC windows and doors, Floor and Wall tiles, Aluminium window and door systems and Exterior Facades, Cold Roll form products etc. Most of these products are available in pan India and international markets through an extensive dealer network which constitutes more than 350 vendor partners for different brands.

Constrofacilitator recently had an exclusive interview with Mr. T. Chandra Sekhar, Technical Director, Aparna Enterprises Ltd. He is an industry veteran with 41 years of experience in steel, ceramic, windows and other building materials. He has played an instrumental role in setting up the backward integration for AEL, planning and setting up of RMC plant, state-of-the-art uPVC window fabrication plant, uPVC profile extrusion plant, and Vitrified tiles production plant. With exposure to global practices in these industries, he looks after all the technical aspects of the company’s production facilities.

During the interview, he shared insights on emerging market trends, technological advancements, company product range and much more.

Here are the excerpts from the interview.

1. What are the emerging trends that might impact the market potential for building material products?

Today, the building materials industry is gravitating towards durable and intelligent solutions. The demand for modern, visually captivating, and eco-friendly materials is fundamentally reshaping the market for building material products. The rise in disposable income, coupled with shorter renovation cycles and a preference for better design and aesthetic value is driving consumer’s demand for technologically advanced solutions. From premium flooring materials and eco-friendly, aesthetically appealing sanitary ware to energy-efficient glass facades and sleek yet durable uPVC products, the emerging trends in building material products are undergoing a significant shift. In flooring options, the preference for lower carbon footprint and durability is leading to a shift from traditional ceramic tiles to alternatives like large formatted tiles and eco-friendly options.

Apart from this, an increased trend towards beautification has spurred demand for 3D printed tiles, designer tiles, and eco-friendly alternatives. In the sanitary space, there is a growing demand for designer sanitary ware, green plumbing solutions. Moreover, awareness about safe sanitation and complete bathroom solutions has led to a shift towards touchless, eco-friendly, and water conservation-based products. Consumers are adopting uPVC doors and windows for durability and thermal insulation, energy-efficient glass, and aluminium frames for sleek designs. Moreover, the industry is witnessing disruption with the emergence of tech-based distribution platforms and one-stop shops, catering to all sorts of evolving needs.

2. What are the primary factors influencing customer demand for building material products, and how the company aims to capitalise on these trends?

These days, most consumers are seeking low-maintenance and durable options along with aesthetically impactful solutions that enhance the appearance of their living spaces. In the realm of contemporary design, technological advancements are reshaping the traditional notions. Smart Living has gained the ground so the preferences are towards material that provides smarter solutions. Beyond this the need for sustainable development is continuously increasing due to the demand for reducing carbon emissions.

Aparna Enterprises Limited (AEL) stands at the forefront of construction material manufacturing and building solutions. The company earns and implements the changes in product features in its own construction projects. These insights are incorporated in the manufacturing process and thus shared with other players in the industry. With a legacy spanning over 30 years, we have consistently delivered innovative designs and superior functionality, setting new benchmarks in modern space construction. Our expertise in addressing diverse construction needs enables us to offer customized solutions to a wide range of consumers. Our product range is meticulously crafted to meet contemporary requirements, catering to multifaceted consumer demands. Engineered for precision, durability, noise resistance, and energy efficiency, our products impart a modern aesthetic to both residential and commercial interiors. What sets AEL apart is our ability to fully customize designs and specifications to suit both functional and aesthetic preferences.

3. Can you elaborate on the company’s key product offerings and how they contribute to the building materials industry?

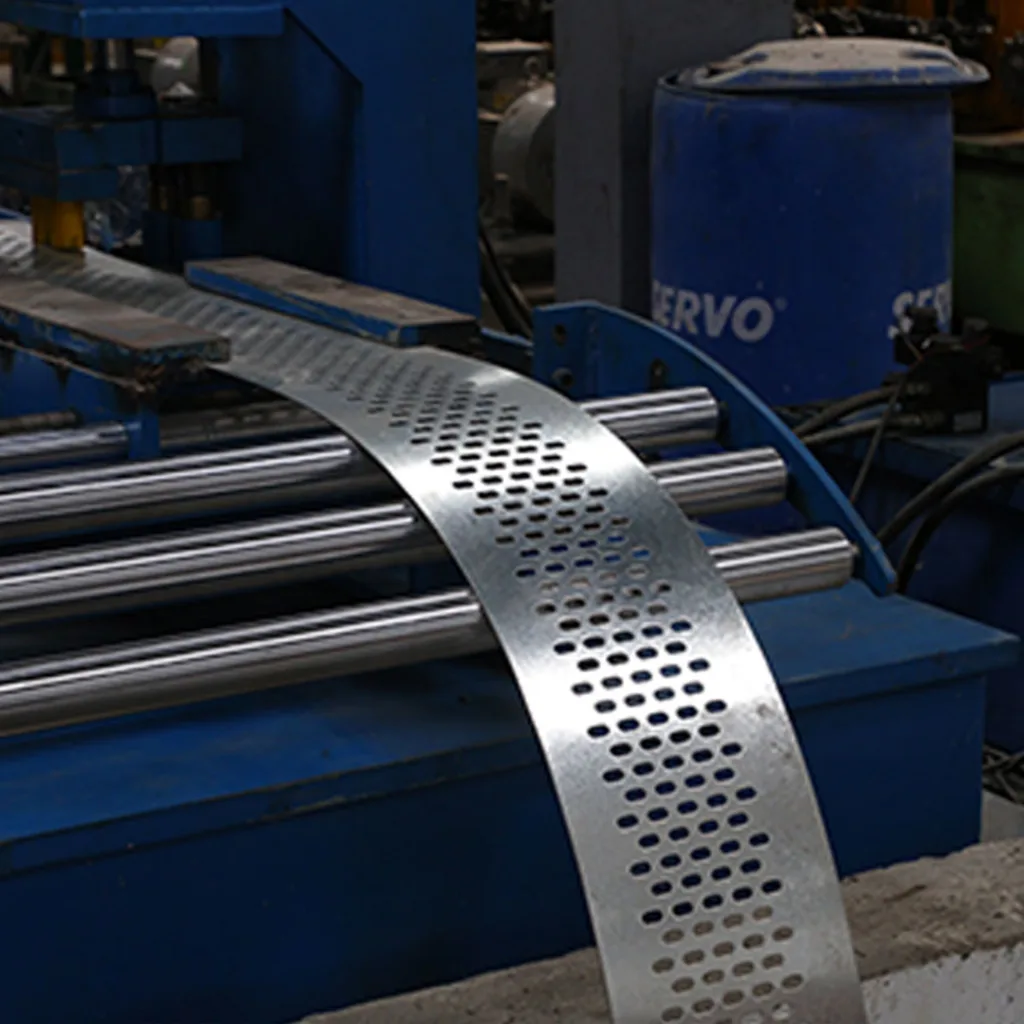

Aparna Enterprises Ltd provides comprehensive one-stop solutions for all construction requirements, catering to both residential and commercial projects. Our diverse product range encompasses vitrified tiles, uPVC windows and doors, uPVC windows and doors, Ready Mix Concrete (RMC), stone aggregates, metal formed items such as steel reinforcements, gratings & cable trays, complete facade solutions, aluminium window and door systems, premium sanitary ware, and a wide array of kitchen and wardrobe solutions.

We are one of the leading tile manufacturers in India. Under its flagship brand, Vitero, the company also manufactures a wide range of vitrified tiles for walls and floors. With timeless designs and top-notch functionality, they can be customized based on the purpose and footfall of the area. AEL also manufactures 60+ uPVC profiles in partnership with Okotech. These products meet stringent European standards and have the power to withstand India’s extreme weather conditions. Beyond that, uPVC profiles manufactured at Okotech have low thermal conductivity which in turn helps save 30% on electricity bills.

Apart from this, the company manufactures high-quality aluminium windows and doors under its brand Alteza. Alteza windows and doors have slim profiles that add a contemporary touch to a building. When pursuing modernity, we are committed to the advancement of exterior facades offered by Aparna-Craft. The company’s facade design innovations, blend contemporary aesthetics with technological advancements.

Additionally we are a frontrunner manufacturer of ready-mix concrete. Equipped with state-of-the-art equipment and machinery, the company’s RMC has evolved to be the one of the largest ready-mix concrete supplier with footprints across Telangana, Andhra Pradesh, Maharashtra, and Karnataka.

4. How does AEL ensure the quality and standardization of its products across different categories?

Built with the confluences of technology, innovation, design, research, resilience, and quality, AEL has a proven track record of delivering high-standard, customised, contemporary building materials and construction solutions. We follow a collaborative approach of treating every project as a partnership endeavour while offering integrated experience, multifaceted expertise, and seamless support to ensure a successful culmination.

The company abides by stringent quality control measures at every stage of the manufacturing process. From raw material sourcing to production and packaging, each step is carefully monitored to ensure adherence to quality standards. The company operates state-of-the-art manufacturing facilities equipped with advanced technology and machinery. These facilities are designed to meet international quality standards and ensure consistency in product quality. Our vitrified tiles and uPVC profiles are BIS certified.

For example, our aluminium windows and doors are built to withstand wind loads of 3kPA. Our aluminium façade solutions are tested to withstand wind and water pressure upto 5kPA. By staying abreast of technological advancements and market trends, AEL ensures that its products remain at the forefront of quality and innovation.

5. How does the company leverage technological advancements to stay ahead in the market and meet evolving customer expectations?

Through advanced technology integration, we are actively strategizing our focus and priority into catalysing a positive impact and crafting a compelling value by solving some of the emerging and key challenges in the construction sector with innovative products, iconic designs, and ingenious and eco-safe solutions. To begin with, our Vitero tiles are meticulously crafted using advanced technology, incorporating an innovative feeding system and nanotech coating to produce premium-grade double charged tiles, digital wall tiles, glazed vitrified tiles, and full body tiles. Our manufacturing facility boasts one of India’s largest and most sophisticated kilns, ensuring optimal production efficiency and product quality.

In addition to advanced manufacturing techniques, we harness the power of digital printing technology to offer our glazed vitrified tiles in a diverse range of textures and finishes, including wood, marble, slate, or bamboo. This level of customization distinguishes our tiles, making them both aesthetically pleasing and functionally superior, catering to a wide array of customer preferences.

We’ve adopted backward integration measures throughout our manufacturing processes, allowing us to produce essential raw materials in-house. Our tile and uPVC profile manufacturing plants generate 18,000 – 20,000 units & 4,000 – 5,000 units of electricity every day through 3.8 MW & 0.8 MW solar plants in respective manufacturing units. This not only ensures consistent quality but also guarantees the continuous availability of raw materials in their purest form, enhancing the reliability of our supply chain.

Furthermore, our machinery is meticulously engineered to surpass stringent European product standards, ensuring top-notch performance even in challenging weather conditions. This steadfast commitment to quality enables us to deliver products that not only meet but exceed customer expectations, solidifying our reputation for reliability and excellence.

We’ve also implemented fully computerized ready-mix concrete production plants, enabling us to provide consistent quality and tailor-made concrete mix solutions. Coupled with our round-the-clock customer service, these initiatives underscore our dedication to meeting the evolving needs of our customers while upholding the highest standards of quality and service.

6. How has the company contributed to landmark projects, and share some notable examples?

We have been associated with several landmark projects and prestigious establishments across both public and private sectors like leading brands in India, such as Godrej, Infosys, NCC, Mahindra LifeSpaces, Brigade, and Prestige to name a few. All our building materials are listed and approved by government organizations like DRDO, South Central Railways, PWD, CPWD etc.

We have been a proud partner in several landmark projects which include Telangana secretariat, Statue of equality, Hyderabad ORR, The Park Hyatt-Hyderabad, CBRE-Mumbai, Secunderabad railway station, My Home Nishadha, Infosys campus in Pocharam, IIT Dharwad, prestigious projects by Phoenix group – Sparkle one office- Bengaluru, Wakad towers- Pune & Phoenix market city mall-Chennai to name a few.

7. What expansion plans or strategies does AEL have, considering its operations both nationally and internationally?

We are strategically expanding our market presence to meet the robust demand for construction materials. Domestically, we recently extended our reach into North Indian markets with our renowned uPVC doors and windows brand, Ökotech. Furthermore, we have successfully entered international markets, including Vietnam, Bangladesh, Sri Lanka, and Nepal, with our innovative product range. Notably, we have inaugurated a state-of-the-art manufacturing unit in Rudraram, Hyderabad, representing a significant investment of Rs 100 crore in UPVC production. Very soon our powder coating plant will become operational, which will reduce our dependence on outside vendors. This plant will be Qualicoat certified by the end of this year. Qualicoat certification will allow us to powder coat products for exporting purposes.

In addition to geographical expansion, we are enhancing our retail footprint by introducing company-owned stores that offer a diverse range of solutions under one roof. Last year, we unveiled the ‘Unispace’ showroom in Bangalore, catering to the diverse needs of our customers. Furthermore, we are expanding our Vitero select stores in Mumbai and extending our retail network across key cities.

Our Ready-Mix Concrete (RMC) business has also witnessed remarkable growth, and we have established new units across Western and Southern regions of the country. Additionally, we are advancing our offerings under the Alteza brand and strategizing to penetrate new markets throughout India. With a strong focus on innovation, quality, and customer satisfaction, Aparna Enterprises Ltd remains committed to driving growth and delivering excellence in the construction materials sector.

8. How does the company ensure a consistent supply chain for its diverse range of products, especially considering the various industries it operates in?

We ensure a consistent supply chain for its diverse range of products by implementing robust strategies tailored to the specific requirements of each industry it operates in. Built with the confluence of technology, innovation, design, research, resilience, and quality, we have a proven track record of delivering high-standard, customised, contemporary building materials and construction solutions. The company establishes strategic partnerships with suppliers, distributors, and logistics providers to ensure a reliable supply chain network. These partnerships are built on trust, transparency, and mutual benefit, enabling Aparna Enterprises Ltd to optimize distribution channels for efficient delivery.

Furthermore, the company leverages technology solutions such as enterprise resource planning (ERP) systems, inventory management software, and supply chain analytics to monitor and manage its supply chain operations effectively. Real-time visibility into inventory levels, demand forecasts, and production schedules enables the company to respond promptly to changing market dynamics and customer demands. Senior management ensures deep involvement to make required strategic changes from time to time. A special team coordinates with production and sales teams to ensure a robust supply chain. By adopting a holistic approach to supply chain management, we are able to deliver superior products and services to customers.