Table formwork is used to support concrete slabs during the pouring and curing process. It typically consists of a framework of horizontal and vertical supports, resembling a table, on which the concrete is poured. This formwork system is efficient for large and repetitive floor structures, providing a stable platform for workers and equipment. After the concrete has solidified, the formwork is removed, leaving behind a supported and properly shaped slab.

Components of table formwork

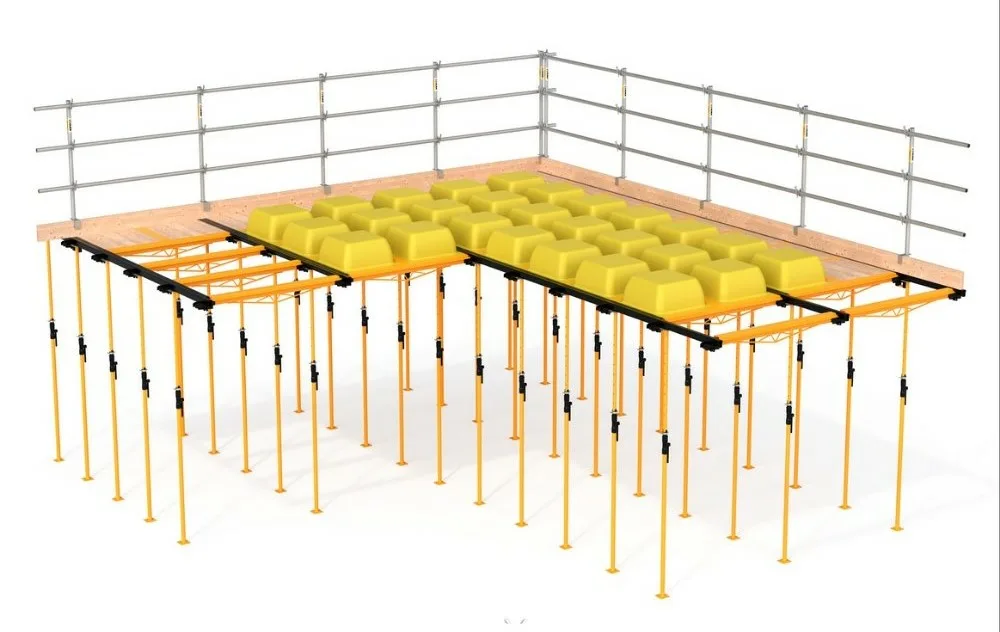

Table formwork typically consists of several key components:

1. Tabletop or Decking: The horizontal surface on which concrete is poured. It can be made of plywood, metal, or other materials, providing a smooth and even surface for the slab.

2. Supporting Structure: This includes vertical supports (usually made of steel or aluminum) that hold up the tabletop. The supporting structure forms the framework resembling a table and bears the load of the concrete and any additional construction loads.

3. Props or Shoring Systems: Vertical supports that transfer the load from the tabletop to the ground. Props are adjustable to achieve the desired height and provide stability to the formwork system.

4. Lateral Restraints: Horizontal bracing or supports that prevent lateral movement of the formwork system. These components enhance the stability of the structure during concrete pouring and curing.

5. Accessories: Various accessories are used to connect and secure the different components of the table formwork system. This may include connectors, clamps, and fastening mechanisms.

6. Formwork Release Agents: Substances applied to the formwork surface to prevent the concrete from adhering to it excessively. This facilitates easy removal of the formwork after the concrete has cured.

7. Safety Features: Guardrails, access ladders, and other safety measures to ensure a secure working environment for construction workers using the table formwork.

8. Casting Sections or Molds: These are used to shape specific elements within the slab, such as beams or columns, during the concrete pouring process.

These components work together to create a stable and efficient table formwork system for the construction of concrete slabs.

Why is table formwork used?

- It is well-suited for large, flat slabs and repetitive floor structures. The system allows for quick and efficient assembly and disassembly, saving time in the construction process.

- It provides a stable and secure working platform for construction workers, enhancing safety during the concrete pouring and curing stages.

- It can be adapted to various slab shapes and sizes. It offers flexibility in design while maintaining ease of use.

- The construction process is streamlined with table formwork, leading to increased productivity. The repetitive nature of the system allows for a smooth workflow.

- Ensures uniformity in the thickness and finish of the concrete slab, contributing to the overall quality of the construction.

- The modular nature of table formwork facilitates rapid assembly and disassembly, reducing downtime between construction phases.

Different types of table formwork?

1. Slab Table Formwork:

Slab table formwork is highly versatile and efficient for horizontal surface construction, particularly slabs. These tables come pre-assembled, allowing for easy movement and adjustment on the construction site. Their design minimizes the need for extensive manual labor, making them a popular choice for projects where speed and efficiency are essential.

2. Flying Table Formwork:

The flying table formwork is engineered for the construction of large slabs with minimal vertical supports. This type of formwork is distinctive for its ability to be moved horizontally, typically using cranes. This feature facilitates the construction of expansive horizontal surfaces with reduced reliance on traditional support structures, enhancing both speed and flexibility in construction projects.

3. Luffing Table Formwork:

Luffing table formwork provides vertical adjustability, making it suitable for projects where varying slab heights are encountered. This flexibility allows for the construction of structures with different elevations while maintaining a streamlined and efficient formwork system. The luffing mechanism ensures that the table can be easily adjusted to meet the specific requirements of each part of the construction.

4. Trolley System Formwork:

Tables equipped with a trolley system are designed for horizontal mobility, enhancing efficiency in large-scale construction projects. The trolley system allows for the easy and controlled movement of the formwork tables along a horizontal plane, reducing the time and effort required for repositioning during the construction process.

5. System Table Formwork:

System table formwork is a modular and adaptable solution for various slab shapes and sizes. This type of formwork is characterized by its flexibility, enabling the construction of slabs with diverse geometries. The modular components of the system table formwork can be easily assembled and adjusted, providing a versatile solution for construction projects with specific design requirements.

6. Grid Formwork Tables:

Grid formwork tables are designed for complex slab structures that require a high degree of customization. The tables consist of a grid of beams and panels that can be adjusted to form different shapes and sizes. This type of formwork is particularly suitable for projects where the construction design involves intricate slab configurations.

7. Adjustable Table Formwork:

Adjustable table formwork is characterized by its flexibility in adjusting both height and inclination. This adaptability makes it suitable for construction projects with varying requirements. The ability to customize the formwork tables according to the specific needs of different sections of the construction ensures optimal efficiency and precision in the building process.

Application method for table formwork

Table formwork is applied in a systematic process to efficiently create large horizontal surfaces, typically for casting concrete slabs. Here’s a general overview of how table formwork is applied:

1. Preparation:

– The construction team prepares the site by ensuring a level and stable foundation for the table formwork system.

2. Assembly of Table Forms:

– Table forms consist of a framework supported by vertical and horizontal members. The assembly involves setting up the support legs and connecting the horizontal and vertical elements to form a sturdy structure.

3. Positioning of Props and Shoring:

– Adjustable props and shoring systems are positioned strategically to support the table formwork. These props provide the necessary vertical support to carry the weight of the concrete and the formwork itself.

4. Installation of Formwork Panels:

– Plywood or other suitable formwork panels are placed on top of the framework to create the surface where the concrete will be poured. The formwork panels are securely attached to the table form structure.

5. Reinforcement Placement:

– If reinforcement is required for the concrete slab, steel bars or mesh are placed within the formwork at the specified locations.

6. Pouring Concrete:

– Once the formwork is in place and the reinforcement is set, concrete is poured into the designated area. The formwork contains the concrete, giving it the desired shape and structure.

7. Curing:

– After the concrete is poured, it undergoes a curing process to ensure proper strength development. Curing may involve covering the slab with wet burlap, applying curing compounds, or other methods to control moisture and temperature.

8. Stripping Formwork:

– After the concrete has sufficiently cured and gained strength, the formwork is carefully removed. This process is known as stripping. Table formwork systems are designed for ease of assembly and disassembly, allowing for efficient stripping.

9. Reuse or Repositioning:

– Depending on the project requirements, the table formwork system may be reused for subsequent pours on the same site, or it may be disassembled and repositioned for use in different locations.

10. Finishing:

– After the formwork is removed, finishing touches such as smoothing the concrete surface or applying surface treatments may be performed to achieve the desired appearance and functionality.

Applications of table formwork

- Slab Construction

- High-rise Buildings

- Bridge Decks

- Tunnels and Underground Structures

- Residential and Commercial Buildings

- Industrial Facilities

- Parking Structures

Conclusion

Table formwork is a versatile construction method that offers efficiency and adaptability in various projects. Its benefits include rapid assembly, cost-effectiveness, and enhanced safety. The use of table formwork contributes to streamlined construction processes and ensures high-quality results. As the industry continues to evolve, table formwork remains a valuable solution for modern construction projects, providing a stable platform for success.