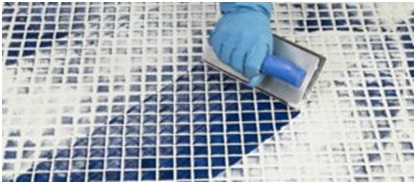

Joint Grout creates a tough seal between the tiles. Tiling with joint grout makes your floor smooth and beautiful. Fixed tile and grout opposes recolouring and staining. You do not harm the surfaces with synthetic compounds or rough items. Tile joint grouts are used as fillers in the space between adjoining tiles laid either on the floor or walls. Traditionally, tiling is done by placing tiles close with white cement used to fill the tile joints instead of tile joint fillers.

Why do you need to leave grout space between tiles?

The main reason for providing a gap between the tiles is to accommodate for slight sizing differences from tile to tile that are created during the manufacturing process. The gap enables the installer to adjust the tile to compensate for these sizing differences and allow for a straight grout line. Due to the technology incorporated in the manufacturing of tile today, there is very little variation in size and therefore grout joint widths are generally much smaller than they have been in the past. Typically, the grout joints should not be less than 3mm.

Also, tiles are subject to thermal expansion & contraction, and these small gaps prevent any possible cracking of the tiles or their detaching from the basis. Laying tiles with small gaps also prevents problems in case of mechanical damage to one of them. If the tiles were indeed laid out without joints, it would not have been possible to safely remove one of them. 1.5 to 2mm gaps are enough for safely replacing a tile without damaging the other ones.

Installing tiles with no grout line would reduce the space between tiles to the minimum but would not eliminate it. The remaining space would allow water to seep between bathroom wall tiles and for dust and dirt to accumulate in the gap between kitchen floor tiles. Hence, without tile joint grouting, tile fixing is half done process.

Use of Tile Spacers are the best and easiest way to ensure that your tiles are set at the correct distance from each other and that the result is even, polished, and professional-looking.

Choosing the right grout size and type.

The size of grout lines for tile is something that comes up with just about every tile installation, and is a question we are asked almost every day.

When choosing a grout, it’s important to consider the final use of the tile installation. In heavy-duty floor tile applications, such as shopping malls or leisure complexes, it’s logical to choose a grout which is able to cope with the increased demands placed on the flooring. The tiled finish will be required to withstand increased abrasion and more frequent foot traffic.

In wet environments, grout, the tile joint filler with reduced water absorption is beneficial. The product must also contain mold inhibitors for added protection in kitchens, bathrooms, as well as in water features.

Types of Tile Joint Grouts

Grout may play second fiddle to tile, but when it goes wrong, it can become all you see. There are so many types of grout from which to choose. So, which one should you use?

Cement Grout

Cement Grout are less expensive and the haze over the tiles or dropped lumps can be cleaned without much effort, even long after application. Sunshine won’t harm the aesthetics of cement grout. However, Cement-based grout products are porous in nature. The problem with this is, the pores allow dirt and other outside elements to find their way into the grout where it becomes embedded. This causes staining and even allows mold and mildew to embed itself into the grout and the color changes over time. Regular use of tile and stone grout cleaners can extend the life and durability of the applied grout.

Latex Modified Grouts

The Cement based tile joint grout is modified with a latex polymer additive in the dry mix (Ardex Endura Super Grout) or by adding it (Ardex Endura GT1) while mixing grout with water. This additive plays an essential role in enhancing the grout’s water-proof nature and increasing its strength.

Epoxy Grout

Epoxy grout is epoxy tile joint filler (resin and hardener and filler) becoming the new standard in tile joint grouting. It does not use Portland cement or water in the mixing process. It features a hardener, pigments, epoxy resin, and silica fillers. The real strengths of Epoxy Grout are water absorption, strength, and chemical resistance. Epoxy absorbs about 50-times less water than traditional cement grouts (hence, can be considered as best waterproof epoxy grout), has double the strength, and chemical resistance that stands up to even the toughest environments

Furan Resin Grout

Furan grout is similar to epoxy, but it is made of polymers of fortified alcohols and has unsurpassed chemical, physical and thermal-resistance.

ANSI (American National Standards Institute), under section A108.01, 2005-3.7 together with common industry practice, recommends expansion joints in tile installations at the following distances: Interior applications require joints at 24-32 feet in center. Exterior applications or interior in direct sunlight require joints at 8-12 feet on center.

EPOXY GROUT manufactured by ARDEX ENDURA is hygienic, stain-resistant, 3 component epoxy resin-based grout with a high degree of resistance to chemical attack, abrasion and impact. The cured grout does not transfer stains to food products, prevents the entry of bacteria or dirt and is easily maintained in a sterile condition. EPOXY GROUT is designed for grouting glazed tiles, mosaic, vitrified and fully vitrified tiles, ceramic tiles, industrial tiles, granites, marbles & other natural stones, etc.

These products meet the requirements of EN 13888 and conform to the Global Migration Test laid by USFDA for intended use for contact with aqueous food & beverage (water based) products.