Shredder machines are used to process and reduce construction and demolition waste, such as concrete, wood, metal and plastics, into smaller, reusable components. Equipped with powerful motors and durable blades, these machines break down large and cumbersome debris into manageable sizes, making it easier to recycle or repurpose materials for use in new construction projects. They not only help lower disposal costs but also contribute to environmental preservation by minimizing landfill waste. Their adaptability to handle various types of materials makes them a vital asset in improving waste management processes in the construction sector.

Shredder machines are used for:

- Recycling Waste: Processing concrete, wood, metal, and plastics for reuse.

- Waste Reduction: Reducing waste volume for easier disposal.

- Material Recovery: Extracting reusable materials for resale or repurposing.

- Soil Remediation: Shredding hazardous materials for safe disposal.

- Recycled Aggregates: Converting demolished concrete into new construction material.

- Waste-to-Energy: Shredding organic waste for fuel production.

- Wood Recycling: Processing wood debris for landscaping or biofuel.

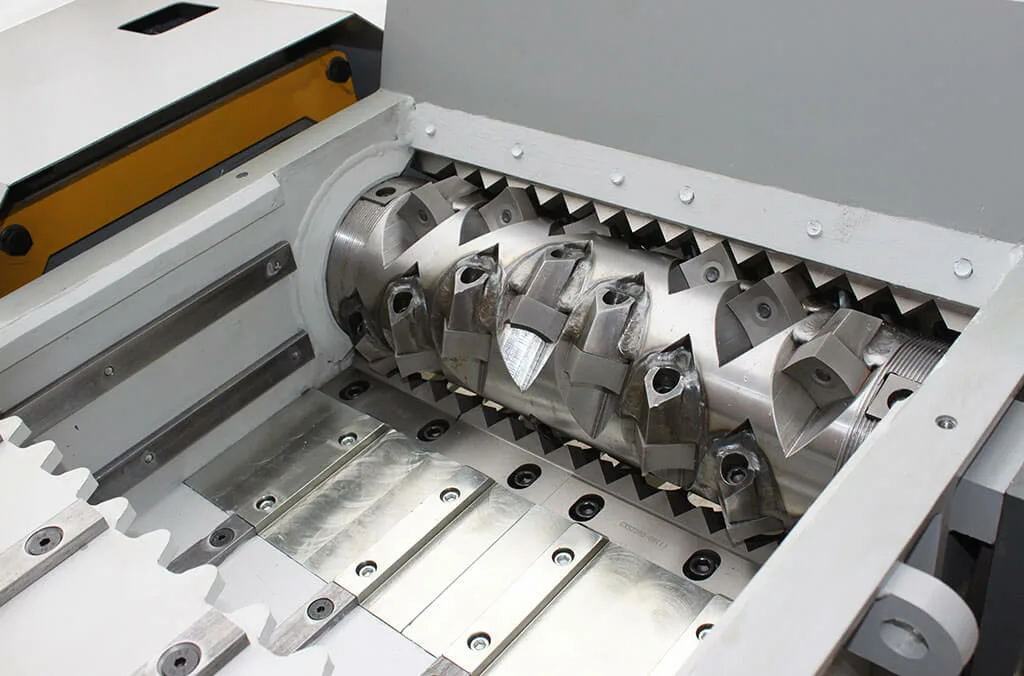

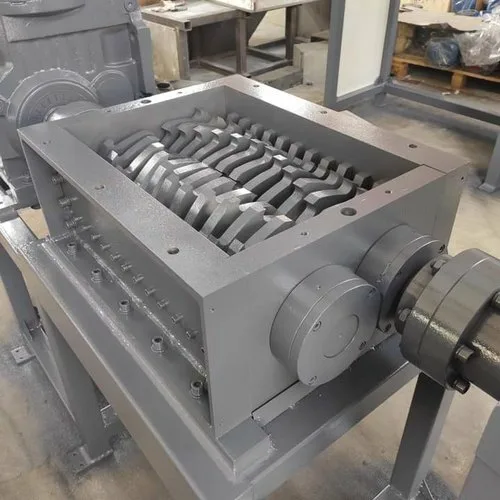

Shredder machine consist of several key components:

- Blades/Cutters: Sharp, durable parts that break down debris into smaller pieces.

- Motor: Powers the blades with high torque for effective shredding.

- Hopper: The intake area for loading materials into the machine.

- Feed Roller: Moves materials into the shredding chamber.

- Shredding Chamber: Where the material is shredded by the blades.

- Drive System: Transfers power from the motor to the blades.

- Screen: Controls the size of the shredded output.

- Discharge Chute: Directs the shredded material to a collection area.

- Hydraulic System: Powers feed rollers or adjusts blade gaps for tougher materials.

- Frame and Body: The structural base, ensuring stability and protection.

Shredder machine advantages

- Significantly reduces the volume of construction debris, making disposal easier.

- Lowers transportation and disposal costs by reducing waste size.

- Enables reuse of construction materials, reducing the need for raw resources.

- Simplifies the process of sorting and recycling various materials.

- Helps reduce landfill waste, contributing to a more sustainable construction industry.

- Speeds up the recycling process, saving time and labor.

- Reduces the risk of accidents by processing waste in a controlled, machine-driven environment.

- Handles a wide range of materials, including concrete, metal, plastic, and wood.

- Extracts valuable materials, like metal or wood, for resale or repurposing.

- Shreds hazardous materials, making them safer for disposal or recycling.

- Helps meet environmental and recycling regulations.

- Produces uniform and usable materials for future construction projects.

Shredder machine types

- Single-Shaft Shredders: These shredders are equipped with a single rotor that features sharp, durable blades designed to shred materials like wood, plastics, and rubber. Known for their precision, single-shaft shredders are ideal for applications requiring uniform particle sizes. They are commonly used in construction recycling where controlled and consistent output is important for further processing or reuse.

- Double-Shaft Shredders: With two counter-rotating rotors, double-shaft shredders are designed to handle heavy-duty tasks. These machines are highly effective in breaking down tough materials such as concrete, metals, and mixed construction debris. Their robust design ensures that even bulky or irregular waste can be processed efficiently, making them a popular choice in demanding recycling applications.

- Horizontal Shredders: Horizontal shredders are specifically engineered to process long and bulky materials such as wooden planks, pipes, and metal beams. They use horizontal feeding mechanisms to ensure smooth operation and consistent shredding. These machines are particularly useful on construction sites where large, elongated debris needs to be reduced for easier handling and recycling.

- Vertical Shredders: These shredders feature a vertical chamber that is ideal for compact and smaller items such as cables, wires, and compact construction debris. The vertical design ensures easy feeding of materials, and the shredding process results in manageable sizes suitable for recycling. Their compact structure makes them suitable for operations with limited space.

- Four-Shaft Shredders: Four-shaft shredders are equipped with four cutting shafts that offer advanced shredding capabilities for mixed and complex materials. These machines are effective at simultaneously shredding and separating materials like metal, concrete, and plastics, which makes them ideal for recycling applications requiring thorough material reduction and sorting.

- Mobile Shredders: Designed for flexibility, mobile shredders can be transported to different construction or demolition sites for on-site waste processing. These machines are perfect for projects where transporting waste to a central facility would be inefficient. They effectively reduce waste volumes on-site, cutting down on disposal and transportation costs.

- High-Speed Shredders: These shredders operate at high rotational speeds, making them suitable for lightweight materials such as wood, green waste, and soft plastics. They are designed for fast and efficient material reduction, ensuring high throughput in environments where speed is important, such as large-scale recycling operations.

- Slow-Speed Shredders: Built for heavy-duty performance, slow-speed shredders operate at lower speeds to provide controlled shredding of dense materials like reinforced concrete, metal components, and other tough debris. Their low-speed operation minimizes wear and tear, ensuring durability and making them reliable for long-term use in challenging conditions.

- Industrial Shredders: These heavy-duty machines are designed for large-scale recycling facilities and are capable of handling high volumes of mixed construction and demolition waste. They feature powerful motors and robust cutting mechanisms, making them efficient at processing diverse materials over prolonged periods, ensuring consistent and reliable performance.

- Rotary Shredders: Rotary shredders use rotating drums fitted with cutting teeth to shred bulky materials such as large metal parts, concrete slabs, and other oversized debris. Their powerful shredding action ensures efficient size reduction, making them essential for applications involving heavy and cumbersome construction waste.

The Demand for Shredder Machines in Construction Recycling

The increasing focus on sustainable construction practices has amplified the demand for shredder machines in the construction industry. With escalating construction and demolition activities generating substantial waste, shredders offer an efficient solution for recycling materials like concrete, wood, metal, and plastics into reusable resources. This not only reduces landfill dependency but also supports resource conservation.

Stricter government regulations on waste disposal and the cost benefits of using shredded materials as aggregates or raw inputs for new projects are driving their adoption. Contractors and developers are investing in shredders to meet environmental standards, reduce waste management costs, and align with green construction initiatives. As urbanization and sustainable development needs grow, the market for shredder machines in construction recycling is expected to see sustained expansion.

Conclusion

Shredder machines are important for enhancing waste management and promoting sustainability in the construction industry. By efficiently processing construction and demolition debris, they help reduce environmental impact, cut costs, and support the reuse of materials. As the demand for sustainable practices grows, shredder machines will remain importantl in driving a more efficient and eco-friendly construction sector.