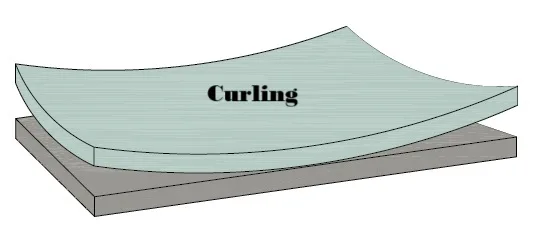

What is Curling?

Curling is the distortion of a slab into a curved shape which is caused by the upward or downward bending of its edges. This phenomenon primarily occurs due to differences in moisture and/or temperature between the top and bottom surfaces of a concrete slab.

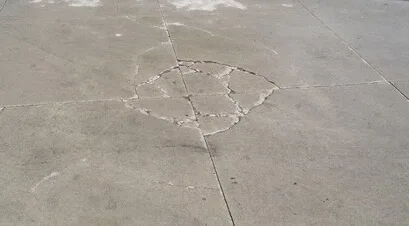

The distortion may cause the edges or the center of the slab to rise from the base, leaving an unsupported portion. The slab section can crack when loads exceeding its capacity are applied Additionally, the edges of the slab may chip or spall as a result of traffic when the slab section curls upwards at its edges. Typically, curling becomes noticeable at an early stage; however, it is also possible for slabs to curl over a prolonged duration.

Curling in concrete floors

Curling is a significant challenge during the process of installing super-flat floors. In the case of indoor concrete slabs, curling is almost always caused by a differential moisture gradient in the slabs. As the surface of the concrete slab dries faster than its body and bottom, a differential moisture profile is developed throughout the thickness of the slab.

The surface of the slab shrinks more and quicker than its bottom. This variation in drying shrinkage creates a gradient that leads to the curling of the concrete slab. The greater the gradient is, the greater the curling.

When the curled edges are subjected to loading, for instance by forklift trucks, there is a risk that the unsupported edges may develop cracks. Such cracks subsequently lead to maintenance issues. Even in the absence of cracks, the curled edges can still pose challenges. Vehicles transporting loads may experience difficulties when navigating over the curled edges, and in high bay warehouses, forklifts may struggle to properly align with pallets located on upper racks.

Thin slabs and long joint spacing may elevate the likelihood of curling and for this reason applications such as thin unbonded toppings need to have close joint spacings However, this requirement for close joint spacing can be problematic in large industrial floor slabs due to the heightened risk of joint deterioration and the associated increase in maintenance needs.

What Causes Curling in Concrete Slabs?

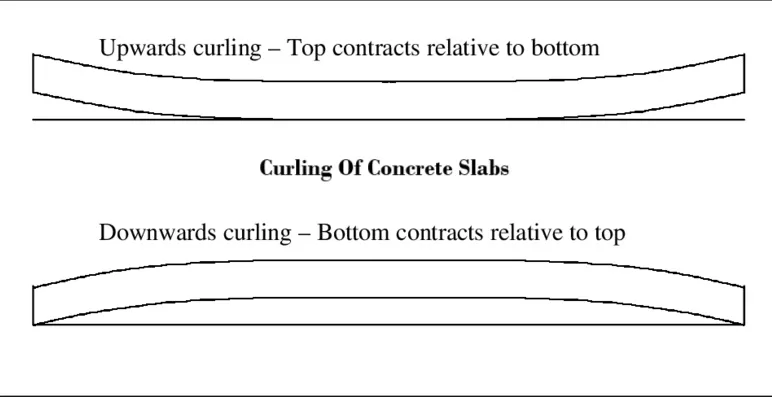

Changes in the dimensions of a slab that lead to curling are most often associated with variations in moisture and temperature across the slab. When one side of the slab experiences a change in size compared to the opposite side, the edges of the slab will bend in the direction of the side that has contracted.

The most common occurrence of curling is when the top surface of the slab dries and shrinks with respect to the bottom. This results in an upward curling of the edges of the slab. The curling of a slab soon after its placement is typically associated with inadequate curing and swift drying of the surface.

In concrete slabs, excessive bleeding can occur as a result of high water content in the mix or water applied to the surface. Additionally, insufficient surface moisture due to inadequate curing can lead to increased drying shrinkage at the surface compared to the bottom of the slab. This bleeding phenomenon is particularly pronounced in slabs that are laid directly on a vapor retarder, such as polyethylene sheeting, or when topping mixtures are placed to existing concrete slabs. Consequently, the shrinkage variations between the top and bottom of the slab in these situations are more significant than those observed in slabs situated on absorptive subgrades.

One additional factor that may lead to curling is the variation in temperature between the upper and lower sections of the slab. The upper portion, which is exposed to sunlight, will expand in comparison to the cooler lower section, resulting in a downward curling of the edges.Conversely, on a cold night, as the top surface cools and contracts in relation to the bottom surface that remains in contact with a warmer subgrade, the curling resulting from this temperature difference will compound the upward curling induced by moisture differentials.

Strategies to Reduce Slab Curling

The main elements influencing the dimensional alterations in concrete that result in curling include drying shrinkage, construction methods, the presence of moist or wet subgrades, and fluctuations in temperature between day and night. The following practices will help to minimize the likelihood of curling.

1. Mitigate Drying Shrinkage

Drying shrinkage, to some extent, can be mitigated by using the lowest effective water content for the concrete mix and by using the largest possible sized coarse aggregate.

2. Prevent Bleeding

All precautionary measures to prevent excessive bleeding should be implemented during construction. Bleeding, to some extent, can be avoided by placing the concrete on a surface that is damp or absorptive. This helps to prevent the bleed water from coming on the top. It is advisable to utilize this method when constructing interior slabs.

3. Reduce cement content

Always employ the necessary cement content. In situations where a high cement content is required, incorporating pozzolanic materials such as fly ash or silica fume can serve as a viable alternative.

4. Quality Curing of Concrete Slab

Ensure that the concrete is cured properly, including the joints and edges of the slab. When the membrane curing method is used, the application of the membrane is performed twice. The second application is done at right angles to the first application.

5. Thickness of the concrete slab

It is advisable to construct a slab with greater thickness to mitigate curling. Alternatively, ensure that the edges have an enhanced thickness. Also use a joint spacing that does not exceed 24 times the thickness of the slab.

6. Proper Steel Reinforcement

Well-designed and strategically positioned steel reinforcement can mitigate curling to a certain extent. Any load transferring devices used to prevent the vertical movement is placed across the direction of construction joints.

7. Use of Sealers and Coatings

Unique breathable sealers are available that help to minimize the difference in moisture, thereby preventing curling.

In situations where curling in a concrete slab application is unacceptable, alternative solutions include the implementation of shrinkage-reducing admixtures, the use of shrinkage-compensating concrete, the adoption of post-tensioned slab construction, and the application of vacuum dewatering techniques. It is essential to make these decisions prior to the commencement of construction, as they may lead to an increase in the project’s initial costs.

Various approaches to address slab curling involve ponding the slab to mitigate curling, subsequently sawing additional contraction joints; grinding the slab joints where curling has taken place to regain functionality; and injecting grout to fill voids beneath the slab, thereby restoring support and preventing the break-off of uplifted edges.

Conclusion

In summary, curling is a common problem in concrete slabs that can lead to expensive repairs and safety hazards. To mitigate curling, start with a proper concrete mix, use proper placement and finishing practices, and ensure proper curing with a high-quality curing agent. If curling does occur, the best repair method is to grind down the high portion of the slab. By following these best practices, one can significantly reduce the risk of curling and ensure a strong and durable concrete slab.