A road header is specialised machinery designed for excavating hard rock and soil in the construction of roadways, tunnels, mining and other underground projects. “It features a powerful, rotating cutter head at the front, equipped with sharp cutting tools that can effectively slice through rock and soil while minimising vibration and noise. The machine is typically tracked, allowing for stable movement in confined spaces and uneven terrain. The importance of road headers in modern construction lies in their ability to increase productivity, reduce the need for blasting, and enhance precision in excavation, making them invaluable for multiple project applications.

Road headers are used in several key applications, including:

- Tunnelling

- Subways

- Mining

- Hydropower

- Cavern Excavation

- Metro and Railway

Key components of a Road Header include:

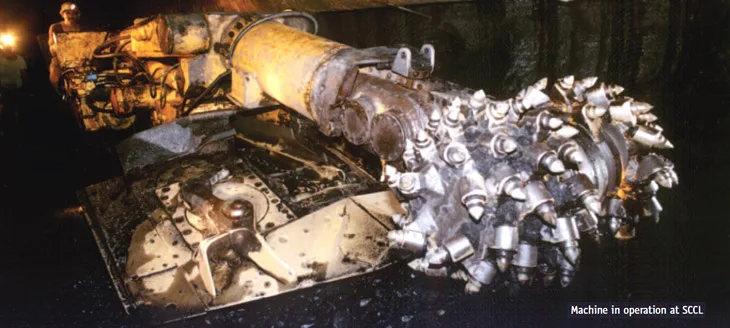

- Cutter Head: Rotates to excavate rock and soil.

- Boom: Manoeuvres the cutter head for precise control.

- Hydraulic System: Powers boom movement and other functions.

- Conveyor System: Moves excavated material for removal.

- Track System: Provides mobility in confined spaces.

- Operator Cabin: Contains controls for machine operation.

- Dust Suppression System: Minimises airborne particles.

- Power Supply Unit: Powers the machine, either electrical or diesel.

- Cooling System: Maintains safe operating temperatures.

Advantages of Road Headers

- Efficient excavation in hard rock and mixed ground conditions

- Precise control over cutting depth and angle

- Continuous operation without frequent stoppages

- Reduces overall project time with faster excavation

- Versatile use in mining, tunnelling and civil projects

- Compact design allows operation in confined spaces

- Lower environmental impact with dust suppression systems

- Enhanced safety for operators due to advanced control systems

- Reliable performance in varying geological conditions

- Energy-efficient options reduce operational costs

Types of Road Headers :

1. Standard Road Headers

Standard road headers are versatile machines designed for general-purpose excavation and tunneling. Equipped with a rotating cutter head, they effectively remove material in various geological conditions. These machines feature a durable cutter head with robust bits for efficient rock and soil excavation, along with a conveyor system that enables continuous material transport away from the cutting area. Their crawler tracks provide enhanced mobility over rough terrain. The advantages of standard road headers lie in their efficiency and speed, which significantly reduce project timelines, as well as their flexibility in adapting to different geological conditions. Additionally, they minimize disturbance to the surrounding environment through reduced vibration and noise. Standard road headers are commonly employed in metro rail construction and underground utility projects, facilitating the efficient excavation of tunnels beneath densely populated urban areas.

2. Heavy-Duty Road Headers

Heavy-duty road headers are specifically designed to tackle tough geological conditions, making them ideal for excavating hard rock. These machines feature more robust components, allowing them to withstand the increased wear and tear associated with challenging excavation tasks. With enhanced cutter head designs and stronger bits, heavy-duty road headers can effectively cut through hard rock, while more powerful hydraulic systems boost their cutting performance. The reinforced frames contribute to their durability and longevity during demanding operations. The advantages of using heavy-duty road headers include high efficiency in hard rock environments, which reduces the need for blasting and enhances safety by minimizing reliance on explosives. These machines are commonly utilized in major infrastructure projects, such as constructing tunnels for highways and railways in mountainous regions.

3. Compact Road Headers

Compact road headers are smaller, more maneuverable machines tailored for use in tight spaces, making them ideal for urban environments where space is at a premium. Their compact design allows for easy navigation in confined areas, and they are equipped with advanced hydraulic systems for precision cutting. Additionally, these machines often feature versatile attachments that enable them to handle various excavation tasks. The advantages of compact road headers include enhanced maneuverability, allowing for efficient operation in urban settings, as well as lower operational costs due to reduced fuel consumption and maintenance needs. Their ability to operate in areas inaccessible to larger machines makes them particularly valuable. Compact road headers are commonly employed in city infrastructure projects, such as water supply and sewage systems, where precise excavation is important.

Conclusion

Road headers are essential machines in the field of tunnelling and excavation, offering reliable equipment for a wide range of geological conditions. Their efficiency, precision, and safety features make them critical in modern construction projects, from urban infrastructure to complex underground tunnels. With advancements in technology, such as remote operation and enhanced cutter designs, road headers continue to evolve, providing faster, safer, and more cost-effective excavation methods. As industries continue to expand, road headers will remain a key asset in shaping the future of underground construction.

Image Source: sany.in, aphmel.com, rocktechnology.sandvik, directindustry.com