ESD flooring is created from a combination of materials, including carbon fibers that transfer the electrostatic charge from a person to the flooring. Thus, reducing the chance of someone creating a static discharge through physical contact. Electrostatic discharge can cause significant injury, damage, and financial loss. Failure of components used in solid-state electronics, like integrated circuits, affects an array of industries. With damage to critical parts comes major financial loss. These floors come in several styles, including carpet, vinyl, and rubber.

ESD Floorings serve as a conduit for an electrical static charge. The static charge that accumulates in the body when walking on an insulated floor was always a concern for designers especially if the plant handles sensitive electronic equipment or potentially explosive chemicals. Thus it becomes very important not to allow static charge to accumulate and thus ESD floorings provide the best protection by providing conductive/dissipative properties along with seamless, jointless, chemical resistant floorings. The application areas of ESD floorings include electronics, ordnance factories, solvent-handling areas, operation theatres etc. to Fit My Floor World.

The science behind ESD

Static builds when you rub two materials together (in scientific terms this is when electrons on the surface of one object pass to another object). This caused the object to become positively charged. This charge will then pass through your body and escape when it can. Hence why we experience what we refer to as ‘electric shocks’. This is an ESD event.

The ‘electric shocks’ we experience in our day to day lives do not have a large voltage, so you are unlikely to see the electricity pass. However, on particular occasions, you can see large jolts of ESD. In these instances, it can create a spark visible to the naked eye. An example of this is lightning which is a large-scale ESD event.

We experience occurrences of static electricity every day. While this sudden discharge of static electricity does not result in any harm to the human body, it can be very damaging to electronic devices that are sensitive to electrostatic discharge (ESD). Electronic devices can be damaged by ESD that is imperceptible to the human body. This document is intended to shed some light on the sources of ESD and provides guidelines on the prevention and control of ESD.

One of the causes of ESD events is static electricity. Static electricity is often generated through tribocharging, the separation of electric charges that occurs when two materials are brought into contact and then separated. Examples of tribocharging include walking on a rug, rubbing a plastic comb against dry hair, rubbing a balloon against a sweater, ascending from a fabric car seat, or removing some types of plastic packaging. In all these cases, the breaking of contact between two materials results in tribocharging, thus creating a difference of electrical potential that can lead to an ESD event.

Another cause of ESD damage is through electrostatic induction. This occurs when an electrically charged object is placed near a conductive object isolated from the ground. The presence of the charged object creates an electrostatic field that causes electrical charges on the surface of the other object to redistribute. Even though the net electrostatic charge of the object has not changed, it now has regions of excess positive and negative charges. An ESD event may occur when the object comes into contact with a conductive path. For example, charged regions on the surfaces of styrofoam cups or bags can induce potential on nearby ESD sensitive components via electrostatic induction and an ESD event may occur if the component is touched with a metallic tool.

Advantages of ESD Flooring

Many businesses and industries are involved in projects and product creation that require an environment free from additional electrical activity. From biomedical research to electronics manufacturing, you need to do everything possible to prevent any electrostatic discharge or buildup as your workforce moves around. The advantages of ESD flooring are-

- Controls Electrostatic Discharge by eliminating catastrophic failure

- ESD flooring reduces the risk to your components effectively. Without the right kind of anti-static flooring, the money, time and energy you put into producing electrical components can be wasted.

- Not all damage is immediately apparent. ESD can cause after-market failures, which translate into disgruntled “ex-customers”. The hidden damage of latent failure is a nerve-wracking experience for a factory manager.

- The most versatile static control flooring is highly reflective. A big advantage of ESD Control Flooring is the high gloss it produces.

- You can choose from a vast swatch of vivid, bright tones. And it can be applied as a transparent top coat over quartz and flake floors.

- ESD floors require much less care than regular flooring, and its maintenance is very simple but requires expert knowledge to prevent damage.

- ESD flooring reduces electrostatic discharge preventing interference and damage to electronic equipment and keeping all information safe.

Selection of ESD Flooring standards

The principal cause of static electricity is frequently cited as the movement of people and materials in the work environment. This routine movement, particularly the contact and separation of the shoe from the floor, generates charges as high as several thousand volts. Similarly, the movement of mobile carts or other equipment will generate an electrostatic charge.

When choosing an ESD floor, always test for both electrical resistance (STM7.1) and charge generation (STM97.2-2014).

A floor can be conductive and still generate enough static to damage electronics.

- To be sure you choose the right ESD floor for your application, always evaluate:

- The relevant electrical code

- Industry standards for electrical resistance and charge generation (body voltage)

- Independent test results: resistance (STM7.1); charge generation (STM97.2)

- Footwear used in the space: ESD-protective footwear or regular street shoes

- Any specific requirements for the application

- The demands and constraints of the environment

- Buyer goals and objectives

- A static discharge as small as 20 volts, can damage or destroy microelectronics.

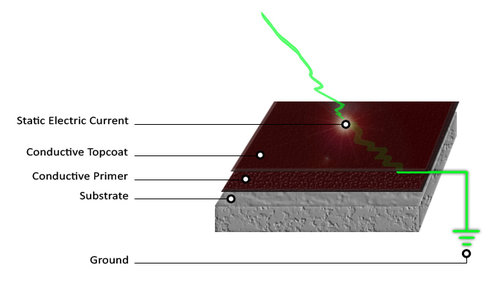

- Static-control floors create a traceable path from the walking surface to the ground.

- To measure the resistance of flooring material, we use the ANSI STM7.1 test method.

- ANSI/ESD S20.20 requires electrical resistance to measure below 1x 10E9 ohms.

- Motorola R56 and FAA 019f, require 1 x 10E6 ohms and below 1 x 10E9 ohms.

- If people wear street shoes in the space, the floor must also prevent charge generation.

- An ESD floor can be conductive and still generate static (fail to prevent body voltage).

- To evaluate the potential for charge generation, use ANSI STM97.2-2014.

Conclusion

Fortunately, there is an easy way to accomplish this: floor coatings with electrostatic discharge (ESD) protection. ESD flooring can be engineered to prevent static from generating and compromising the integrity of a floor system and creating hazards in the workplace.

Info and Image Source:- blackbear concrete, kb.staticworx.com, mrckenkis.com, direct2u.co.uk, ultrastatinc.com, esd-floorcoatings.com, neocrete.co.in, lifetimeflooringsolutions.com