Neocrete manufactures decorative and custom-designed products for floor protection, restoration and renovation of concrete and steel surfaces. These products are based on epoxy, polyurethane and acrylic polymers and designed exclusively against the protection of surfaces against physical, mechanical, chemical and biological attacks.

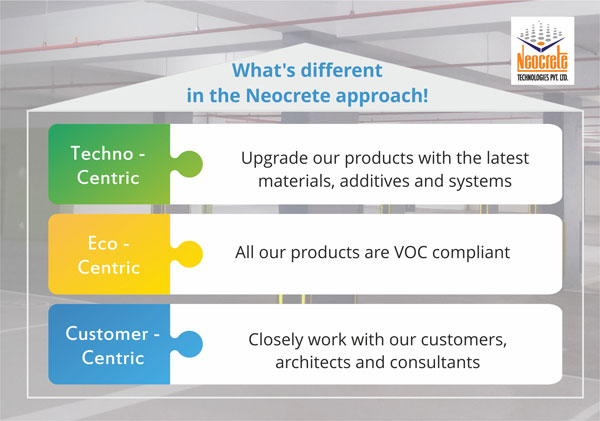

There are hundreds of flooring options to choose from though which can be overwhelming. Moreover, it’s important to choose the right flooring from the outset as the wrong floors can detract from a structure and cost you money to replace should the need arise. Neocrete is solving this issue with a three-way approach- Techno- Centric [upgrade products with the latest materials, additives and systems], Eco – Centric [all products are VOC compliant] and Customer-Centric [closely work with customers, architects and consultants].

Neocrete solutions

They provide solutions for both commercial and industrial flooring.

Industrial

- Solvent-free epoxy/PU

- Water-borne epoxy/PU

- ESD Floorings

- Chemical Resistant epoxy/PU Coatings

Commercial

- Epoxy / Cement terrazzo floorings

- Micro Topping cement floorings

- 3D/Metallic epoxy floorings

- Parking deck Epoxy/PU floorings

- Permeable gravel floorings

- Stamped concrete floorings

Neocrete Technological innovative products

Apart from an array of floor customised and decorative floor products, they have a set of technologically innovative products to add on value for your flooring. The product range comprises of-

- Peelable Coatings

- Epoxy hybrid ready to use rolls

- Image Transfer Adhesive

- Metal Wall Textures

- Imprintable Wall Putty

- Concrete Additive

Neocrete Challenging Its Competitors with Its Advanced Technologies

In 2016 Neocrete began carrying out tests on conductive additives from two global companies. The most impressive results were achieved with the advanced conductive additive TUBALL based on single wall carbon nanotubes produced by OCSiAl. The key advantage of TUBALL is that ultra-low dosages starting from as little as 0.01% are sufficient to provide materials with uniform conductivity and enhanced mechanical properties. TUBALL nanotubes enable manufacturers to achieve conductivity, along with various colors, better yield and performance, in their ESD floorings.For epoxy self-levelling flooring, Neocrete now uses TUBALL COMP_E EPOXY 2% concentrate, which has been specially developed by OCSiAl to simplify the handling of these nanotubes. TUBALL allows manufacturers to even roller coat electrically conductive flooring for refurbishment of preexisting floorings with a wide range of colors. Neocrete can now produce high-grade epoxy floorings in three bright colours – turquoise, green and grey – with electrical resistivity in the range 105-107 ?/sq.

Following the successful completion of various tests, Neocrete is now starting commercial production of epoxy self-levelling floorings for applications in solvent storage, ammunition factories and depots, electronics manufacturing and assembling, computer and electronics installations, clean rooms and other static control installations.

Neocrete’s experience enables them to provide products for a wide spectrum of industries such as Petroleum, Construction chemicals, polymers, printing inks, waterproofing and project management. Their guiding principle is governed by three non-negotiable parameters: Quality, Integrity and ethics.

For more information visit neocrete.co.in