Carbon Fibre Wrapping System is a solution for structural strengthening. Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members. A mix of usually carbon or glass fibre fabrics, and an epoxy resin, wrapping systems are custom designed for each project and application.

Carbon Fibre Wrapping System provides significant strength to structures and protects against further corrosion and erosion. The impervious material will protect a structure from moisture intrusion and further corrosion, reducing the need for ongoing maintenance work. Carbon fibre has extremely high elasticity and is additionally lightweight. When clung to the outside of a solid segment, pillar, or piece, it can include critical quality without including weight that would expand the load on establishments and other structural individuals. A blend of normally carbon or glass fibre textures, and an epoxy resin, wrapping frameworks are specially crafted for each venture and application.

Advantages of Carbon Fibre Wrapping System

Using carbon wrapping for columns reinforcing bars in new concrete can eliminate potential corrosion problems and substantially increase a member’s structural strength. Carbon wrapping for columns this strengthening technique causes minimum disturbance to the structural members as compared to conventional methods. Carbon wrapping for columns is resistant to corrosion; hence they are used for corrosion control and rehabilitation of reinforced concrete structures.

The system consists of Carbon fibre that is made of thin, strong crystalline filaments of carbon that is used to strengthen the material. Carbon fibre can be thinner than a strand of human hair and gets its strength when twisted together like yarn. Then it can be woven together to form cloth and if needed to take a permanent shape, carbon fiber can be laid over a mold and coated in resin or plastic. There are several advantages of this system, some of them are explained below.

- Carbon Fibre Wrapping System provides tensile strength

- It offers high in chemical resistance

- It is temperature tolerant to excessive heat

- It offers low thermal expansion

- Adds strength to concrete

- Increases load carrying capacity

- Restoration of damages of RCC structures

- Elimination of corrosion problems

- Effective in bending and shear

- Protection from environment elements

- Repair or prevent seismic damage

- Replace damaged or missing reinforcing steel

Applications of Carbon Fibre Wrapping System

Carbon Fibre Wrapping System works best for projects subject to progressive collapse and corrosion, including:

- Slabs

- Piers

- Timber Piles

- Docks

- Dams

- Bridges

- Beams

- Commercial piping

- Shaft foundations

- Pile foundations

- Seawalls

- Cement columns

- Pen Stocks

- Water Intake and Discharge Systems

Different types of Carbon Fibre Wrapping System products

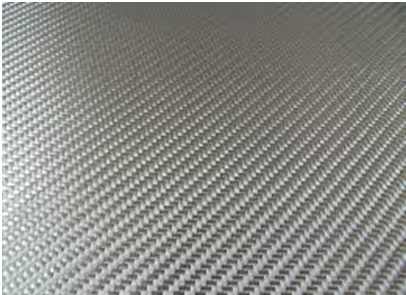

Glass fibre weaving

Glass fibre weaving widest range and the best control over thickness, weight and strength of all forms of fiberglass textiles. This offers the materials engineer a wide choice of controlled fabric properties to satisfy design needs and objectives. It is one of the strongest textile fibers, having greater specific tensile strength than steel wire of the same diameter, at a lower weight. Carbon fibre weaving is made from precursors such as polyacrylonitrile (PAN) and rayon. The precursor fibers are chemically treated, heated and stretched, then carbonized, to create high-strength fibers. These fibers, or filaments, are then bundled together in rows which are identified by the number of carbon filaments they contain.

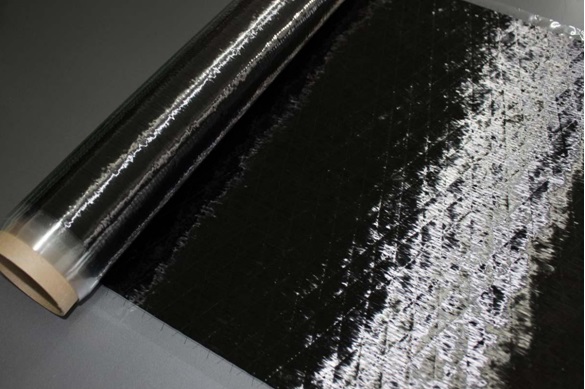

Unidirectional carbon fibre

Unidirectional carbon fibre fabric is a type of carbon reinforcement that is non-woven and features all fibers running in a single, parallel direction. With this style of fabric, there are no gaps between fibers, and those fibers lay flat. There is no cross-section weave that divides the fibre strength in half with another direction. This allows for the concentrated density of fibers that provide maximum longitudinal tensile potential—greater than any other weave of fabric.

Woven carbon fibre

Woven carbon fiber typically comes in the form of a woven fabric, which makes it easier to work with and can give additional structural strength depending on the application. Because of this there are many different weaves used for carbon fibre fabric.

Carbon fibre laminates

Carbon fibre laminates are used in both sporting goods and industrial applications.This is the ideal material giving the laminate stiffness and strength. In addition, laminates have excellent water and chemical resistance. Carbon fibres give improved strength and stiffness properties to the laminates.

Carbon/glass fibre anchors

The use of carbon fibre anchors can increase the amount of tension carried in the CFRP sheets. These have a high corrosion resistance under acid conditions and are well suited for permanent support. The quality material gives high tensile strength, and bolts can be applied with fast setting resin capsules for immediate load bearing as well as cementitious grout. The low weight facilitates handling.

Aramid fibre

Aramid fibre is a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute.[1] The name is a portmanteau of “aromatic polyamide”. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramides have a very high melting point.

Conclusion

There are many reasons for strengthening a structure, such as decreased performance due to fatigue, a change of use, increased loading or required modifications. Herein Carbon Fibre Wrapping System can be applied in single or multiple layers depending on the level of strengthening or increased structural capacity to be achieved. Carbon fibre is not limited to typical plate bonding applications and can also be wrapped around columns and beams, and to improve impact and bursting performance in highways applications. The resin enables the transfer of stresses between the fibres and has the added functionality of protecting the fibres within the wrap.

Image source- Nikol Textile India, Schnell contractors, Horse Construction, Haufer.com, CLM Pro, ThoughtCo, BFT International, Dexcraft