Building Information Modeling (BIM) is a process that begins with the creation of an intelligent 3D model and enables document management, coordination and simulation during the entire lifecycle of a project (plan, design, build, operation and maintenance). BIM is used to design and document building and infrastructure designs. Every detail of a building is modeled in BIM. The model can be used for analysis to explore design options and to create visualizations that help stakeholders understand what the building will look like before it’s built. The model is then used to generate the design documentation for construction.

BIM not only allows design and construction teams to work more efficiently, but it allows them to capture the data they create during the process to benefit operations and maintenance activities. BIM data can also inform planning and resourcing on the project, city or country level. This is why BIM mandates are increasing across the globe.

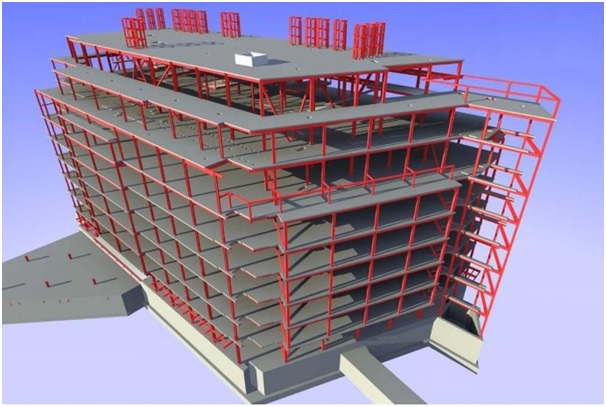

ADOPTION OF BIM IN STEEL STRUCTURES

The evolution of 3D modeling in the steel industry began in the 1990s. In those pioneering days, software had already been developed to automatically produce drawings and reports, extract CNC data, and process individual parts. Fast forward to the 2000s, and fabricators began using BIM to solve even bigger challenges, such as the costly and laborious assembly phase. Using proprietary interfaces, which could harness the power of CNC machines, they enabled fitters to draw information directly onto parts. This fantastic development was made even better in 2004 when automatic layout marking technology became common. From this moment onwards, the industry began to see the huge potential of using BIM to increase productivity.

The demand for productivity drove innovation. Unsatisfied with traditional CNC equipment, the market demanded an automated assembly phase. Thankfully, their dreams came true. Automation has made material handling became more productive. Robotic welding, while not always research- and cost-efficient, has become common. Fabrication-specific software is growing, streamlining processes using BIM information and allowing optimized schedules.

However, as innovation changes the industry, so the tools must change too. For example, robotic welding is more complex than simple replication, and consequently the requirements for information exchange have evolved. To meet new needs, tools like proprietary interfaces have been further developed to transfer information between model and workshop.

With these challenges resolved, the next step was to resolve logistic and scheduling problems using models. Schedules were added, serving as the basis for production schedule planning. Production offices used models to plan logistics before sending information to actual production planning.

Models allowed more information storage, which led to more efficient communication regarding changes. Better, faster understanding of potential changes was possible, even in the midst of on-site work.

Due to the success of these innovations, the demand for more modeled information skyrocketed. Consequently, vendors created proprietary applications with a bidirectional interface (SW or CNC) as a solution. One challenge, however, remained: these technological innovations did not openly communicate with existing tools.

It was time for a new standard. In 2009, leading vendors worked together to create a better workflow for the entire steel fabrication industry. Their goal was to enhance the IFC file format to meet the industry’s needs, making the model a more meaningful part of project workflow. Today, IFC is the industry-standard neutral file format for exchanging BIMs between disciplines.

MAJOR STRUCTURAL BIM ADVANTAGE;

BIM creates efficiency and users will get several benefits. You will realize some of the greatest value of BIM through its potential to cut down on rework, such as re-keying information into models or making changes in the field.

- Better Collaboration and Communication

- Model-Based Cost Estimation

- Structural analysis

- Structural design

- 3D modeling construction

- Increased Productivity and Prefabrication

- Design structural steel

- Steel structure detailing

- Creation of 3D, 4D and 5D BIM services

- Extraction of structural components

- High-quality construction documents

- Clash detection and risk mitigation

- Creation of intelligent parametric libraries

- Accurate quantity takeoffs and Cost estimates

- Improved Scheduling/Sequencing

- Stronger Facility Management and Structure Handover

Case studies for BIM in Steel Structures

Ficep develop a scribing interface through the Steel Projects WinSteel application- Case Study 1

An example of case study is the Tekla solid interface, which has allowed Ficep, an Italian structural steelwork equipment manufacturer, to develop a scribing interface through the Steel Projects WinSteel application. This interface marks the fitting positions and reference information (mark, angle of inclination, amount of weld, etc.), on to the actual structural steelwork member using a special milling head on their latest CNC-controlled saw and drill machines. This saves all the laborious workshop ‘marking out’ time, which in principle is no different from the way that the outline of a stamp is placed on envelopes to indicated their intended position. Welders can then simply weld the fittings in the correct location with all the reference information and weld requirement on the member rather than referring to the fabrication drawings, eliminating another interface for error. All the 3D geometry is transferred to their software systems allowing all holes, copes, member bevels and weld preparation information to be transferred, as all of this information can be far too complex and is not totally supported by the current industry DSTV4 (Deutscher STahlbau-Verband) manufacturing format. In the near future this kind of technology will control welding robots and reinforcement placement robots for the precast concrete sector.

SHANGHAI WORLD FINANCIAL CENTRE, SHANGHAI, CHINA- Case Study 2

This development will, for a short time, become one of the tallest building in the world when it is completed in 2008. It is situated in the Lujiazui Finance and Trade Zone of Shanghai, which is the largest international finance and trade centre in Asia. Limited to a planning height of 492 m above ground level, the 101 floors and three basement levels of the Shanghai World Financial Centre consist of office accommodation, a 15-floor five-star luxury hotel, a six-floor observatory tower, together with conference facilities, shopping and 1100 m2 of car parking, with a total floor space of 381 600 m2 , with 31 elevators and 33 escalators.

Designed by the US architects Kohn Pedersen Fox, this development was originally planned to be built in 1997 when the foundation stone was laid. The project was then temporarily stopped due to fund shortages caused by the Asian financial crisis. The project has undergone many changes, including changing the aperture at the top of the tower from a ‘circular moon gate’ shape to a trapezium, as controversially the original shape was seen to be too much like the form of the Japanese flag. The tower height has also been limited to 492 m from the 510 m of the original scheme. The development team on this US $1·1 billion project was China State Construction Engineering Corporation (general contractor), Leslie Robertson Associates RLLP (structural engineer), with Shanghai Grandtower, Jinggong, scksteel, and Yokomori steel structure being the structural steelwork contractors. The steelwork contractors were responsible for the fabrication of the 60 000 tonnes of structural steelwork. The BIM model was created by Shanghai Tongqing Technology Co. Ltd and Shanghai Rightfly Building Technology Co. Ltd and was built and used for the steelwork contractors design coordination, drawing creation and the production of fabrication information and NC data. This may be an older way of looking at BIM integration. However, it should be remembered that this scheme has been designed over a protracted period of time and a number of steelwork contractors were employed on this project. This may then be seen as a typical way of working on projects produced over the last 10 years just utilizing modern technology.

Architectural, Structural, and MEP Building Information Modeling (BIM) model LOD 350 of Jain Temple (with Classrooms and Building) in the US- Case study 3

Project Summary

- Develop Architectural, Structural, Mechanical, Electrical, Plumbing, Lighting and Civil BIM model in LOD 350 of a Jain Temple with classrooms and building. The client provided us with the .dwg format AutoCAD drawing files for all disciplines.

- Architectural Model – Interior, Exterior and RCP Modelling, Walls, Doors, Windows, Openings, Staircase, Basic furniture, fixtures, roofs, domes, marble cladding, integration with structural discipline, Generic Revit families, miscellaneous items etc.

- There were two architects involved in the design of the temple: the overall architectural design was created by Architect 1, and Architect 2 was responsible for the marble work and carvings on the temple. Tesla had to perform coordination and clash detection between the architectural components of Architect 2 and the architectural design of Architect 1.

- Structural Model – Foundation, columns, beams, floors, roof, joists, Handrail and other miscellaneous items.

- MEP Model – All HVAC, Plumbing Sanitary, Water service, Waste, Vent, and Rain water service, Gas service, Lighting, Power & Fire Alarm. Sheet set-up drawings including tagging, annotations & dimension, coordinated Installation drawings.

- Reflected ceilings and Lighting Model – RCP and lighting layout

- Civil Model – Overall site including grading, roads, landscape, underground utilities, parking etc.

- Provide clash detection & recommendations – Detecting clashes, resolution & co-ordination modeling

BIM implementation in The New Alamein City – Egypt- Case Study 4

The New Alamein City is considered the first model of the new Generation of the millennium cities, its estimated cost 6.000.000.000 EGP, the area of the project 50.000 acres. The works executed by the Arab Contractors Company.

The aim of BIM implementation in The New Alamein City.

- The aim of BIM implementation is to create a centralized shared knowledge resource that contains, All

- the necessary design and operational information about a project. 3D technology had been used to

- present design proposals, with no real on-site application and no ethos of cooperation amongst team

- members to drive its use.

The Steps of Implementing BIM in The New Alamein City.

- Using BIM 360 in Documenting, sharing files, viewing the project and enhancing the collaboration process.

- Using Revit for coordinating and integrating between all disciplines

- Using Navisworks in making time schedule simulation (4D) and cost estimation (5D).

- Using Infraworks 360 for making coordination between all the projects

BIM Value Per Profession

All of the professionals who form part of the design and construction process will get benefits from BIM, value gains are analysed below;

Architects

The evolution of BIM started with architects, and many still see its value emerging from its use in the design phases. Most in the design community, along with many contractors (43%) and owners (41%), say that architects experience a high level of value.

Structural Engineers

Nearly half of all users recognized that structural engineers can garner a high level of value from BIM. Such elements as steel columns, beams and trusses are frequently modeled by users. Contractors are the most likely (47%) to see structural engineers realizing significant benefits.

Construction Managers and General Contractors

Money is largely spent and saved during construction. Reducing rework can help keep budgets in line. Owners are the most likely (57%) to see a CM or GC gaining high value on a project, most likely because that savings could be passed on.

Fabricators

As BIM reduces conflicts and creates confidence in building plans, many team members see opportunities for value in fabrication. Accurate fabrication of materials reduces waste while the pre-assembly can save time. Contractors (56%) are far more likely to see fabricators experiencing a higher value than architects (23%), engineers (38%) or owners (30%).

MEP Engineers

There is a range of opportunities for MEP engineers to use BIM. Modeling larger elements such as duct systems and air handlers are approachable options, while smaller elements such as electrical switches and outlets might prove more challenging. Notably, very few engineers (22%)collectively see MEP engineers reaping high value. Nearly half of contractors (45%) believe MEP engineers see the significant value.

Owners

Owners ultimately experience all value collectively gained on a project. More than half (52%) of owners say they experience high value, but less than 30% of all other users believed this. It could be because other team members recognize that owners have yet to see much value from BIM for use in operations and maintenance. Still, most owners believe they can bank on the value of BIM during design and construction.

Specialty Contractors

Although specialty contractors are charged with executing the complexities of a project, few team members (23%) believe they are experiencing a high value from BIM. Generally, subcontractors are smaller firms relative to general contractors, and the costs of adopting BIM would be more pronounced. As BIM users employ a wide range of software applications, subcontractors may face interoperability issues and suffer added expenses to work within various models.

Building Product Manufacturers

Very few (11%) of build team members see building product manufacturers gaining high value from BIM. It could reflect team members’ belief that BPM’s are not supplying sufficient BIM-related information yet.

Conclusion

BIM implementation within structural engineering methodology clearly and objectively shows how to carry out implementation and includes processes for analysis and diagnosis, rethinking of objectives, identification of requirements, planning, and monitoring of the proposal.

INFO AND SOURCE

Autodesk, Tekls, thebalancesmb.com, onlinelibrary.wiley.com, teslaoutsourcingservices.com, thebimhub.com, slideshare, pinterest