The road construction equipment market is fast-changing with varied requirements of a developing nation. It is no longer enough to create one machine and expect to suit the needs of all. Buyers have become more educated and demanding in terms of wanting machines suited to the kind of work and environment that they work in. The country is in a crucial phase of development where numerous projects are running in different regions, propelling the demand for different types of road construction equipment.

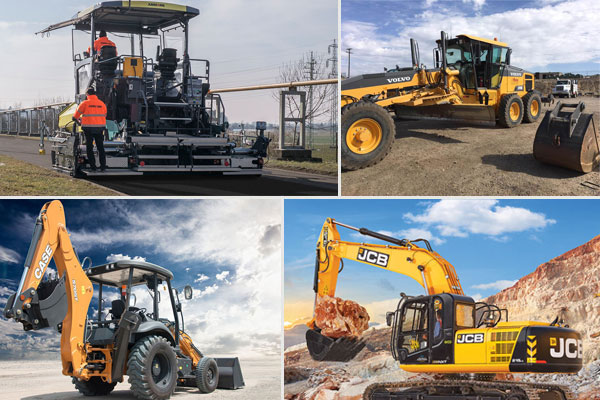

Given below are a few of the most sorted road construction equipment.

Types of Road construction equipment

Excavators for Road construction equipment

Indian Excavator manufacturers are showing preparedness to meet escalating demand by ramping up their production capacities and upgrading machines. Any obstacles in making road chainages are removed by using Excavators. They can be used to rebuild damaged roads, a small hill, or to remove current soil for replacement with a new one. Designed and developed using efficient design philosophy, the new models are equipped with efficiency, performance, comfort and safety innovations. Tracked Excavator is an ideal partner that facilitates site clearance for road construction.

Manufacturers are offering class-leading comfort with less fuel and maintenance costs to ensure you get the most productivity at the lowest cost per hour. The new models offer class-leading comfort with less fuel and maintenance costs to ensure you get the most productivity at the lowest cost per hour. An adjustable seat, easy-to-reach controls, and ISO-certified ROPS protection make for a more pleasant, safer work environment. Increase uptime and reduce costs with extended maintenance intervals.

Models are being designed specifically for the Indian market – will be able to deliver excellent performance in the high temperature, humid working environment. Excavators are now highly efficient, reliable, durable, and energy-efficient. They adopt an environmentally-friendly engine with an all-new load sensing hydraulic system. Advanced features such as the Fuel Saving Pump System enables superior performance in inching operations thereby eliminating losses.

Backhoe loader for Road construction equipment

Backhoe loaders are very common and can be used for a wide variety of tasks. Backhoes are the heavyweights of the range setting new standards in operator comfort, fuel efficiency & performance with the Advanced LiveLink Telematics Technology. The companies have leveraged the integration of Big Data and the Internet of Things in its products. The new models come loaded with ‘Intelli Performance’ and ‘IntelliDig’ technology, which is claimed to give customers real-time information about the performance of the machine.

Models are being re-engineered from the ground up to deliver industry-leading backhoe breakout force, greater loader lift capacity/reach and best-in-class cab visibility. Large box-section structures in high-stress areas such as the boom nose, foot and cylinder enhance the machine’s durability. The new heavy-duty front axle with double effect steering cylinder ensures all wheels remain in contact with the ground even on the roughest terrain, ensuring exceptional stability and reliability. The S-styled backhoe boom delivers excellent breakout forces.

The developed hydraulically shifted clutches allow the operator to change direction and travel speed on the go, while the control valves deliver smooth speed and direction shifts, resulting in smooth and accurate operation. The new tilting engine hood provides excellent access for maintenance. The machine layout has been designed to ensure all daily service points are easily accessible at ground level, for quick and efficient servicing.

Manufacturers are providing substantially more superior machines, with greater reliability, dramatically less maintenance, better operational kinematics, and dynamics with a phenomenal fuel efficiency that saves at least a litre per hour.

For operators, the ergonomic layout, controls, and instruments put you in command. With excellent visibility due to the large, yet narrow excavator-style boom and arm, along with high forces and bucket rotation.

Asphalt paver for Road construction equipment

The asphalt paver is used to lay asphalt on roads, bridges, parking lots, and other such places. The new models feature the two pairs of wheels connected with the chassis utilizing a pivot joint, which allows the wheel pair to oscillate independent of each other and the wheels do not lose contact with the ground when the surface is uneven.

Manufacturers are coming up with hydraulically expandable screeds for contractors seeking easy operation and maximum uptime. The wheeled paver with hydraulically expandable screed is a dual-application machine, handling both asphalt and wet mix. The technology and specifications for the paver meet all governmental requirements in the markets, it has a presence. The paver effortlessly shifts between jobs featuring asphalt and wet mix, often required on some governmental roads.

The new model of finisher paver holds an extension of screed hydraulic to a width of 4.5 meters and a half meters on each side is of Bolton type, which can be removed easily by a loosening of bolts. Additional features include adjustable auger-to-screed distance, dual-screen consoles, remote controls, power slope/power crown, large hopper capacity, maintenance-free auger/conveyor bearings, and built-in SmokEater fume-extraction system.

Motor grader for Road construction equipment

Graders are commonly used in the construction and maintenance of dirt roads and gravel roads. Modern graders come with 12-13 moldboard length and optional air conditioning provisions. The machine has a multi-curvature mould board which reduces the resistance coming on the engine and hence reduces fuel consumption and increases productivity. The added features are structural stability and ease of maintenance featuring ease of engine compartment access along with daily service checkpoints for quick and efficient maintenance of equipment.

Modern models come with sensors that are based on two-dimension technology so that the moldboard angle can automatically adjust itself to the gradients to be graded. The automated technology solution optimizes the operator’s job, which is critical as most road projects have very constrained schedules.

Concrete Batching plants for Road construction equipment

A concrete batching plant for road construction is mainly used for concrete production of the road project, while the commercial concrete batching plant is mostly used to produce and sell various types of concrete.

Manufacturers have adopted technological modifications such as Internet of Things (IoT) solutions, IoT Ready, IoT abled, dashboard for batching plants, gateway device, Hitech weighing system, smart track and concrete transit mixer with a mobile app.

Machines have evolved over a period based on the inputs from customers to cater to their concreting needs. Planetary Mixers for Precast application which is considered superior over conventional Turbo Mixer is in demand. In Planetary Mixer the mixing flow is highly efficient due to integrated action of central stars combined with different peripheral scrapers, which is best suited for Precast structures of concrete with aggregate sizes less than 40mm.

The Inline reduced Bin (IRB Series) batching plant is now designed for sites that require continuous production of concrete and also where the loading of aggregates cannot be done from both sides of the bins due to site constraints. The unique feature of this plant is that the aggregates are weighed in a conveyor rather than the skip unlike other plants, thereby reducing the cycle time and also Water and Cement batching are done in parallel to reduce cycle time and optimize productivity.

Loader for Road construction equipment

A loader is a heavy equipment machine used in construction to move aside or load materials. Modern models come with engine meeting BS-III norm L946 is a loader meant for loading & unloading loose materials, with high reliability & great cost-performance.

Widely used in farms, small mine farms, & town constructions, this is a versatile machine. Designed with a promise to deliver way beyond than you are used to, the best is now a step ahead. Some of its features include saving up to Rs 4.06 lacs/year with greater fuel-efficiency, Improved productivity by 11%, and Higher uptime with robust structure and reliable components.

Ergonomically positioned controls, industry-first side lighting, and improved reliability and serviceability help you get more work done daily. The wide door repositioned grab handles and a lower threshold provide easy access to the cab. Recent machines provide plenty of room for comfortable operation, with greater headroom and legroom, more space between the control levers, and easy access to the seat. Modern models provide plenty of room for comfortable operation, with greater headroom and legroom, more space between the control levers, and easy access to the seat.

Image Source: casece.com, volvousedce.com, schwingstetterindia.com, ammann.com, jcb.com