Introduction

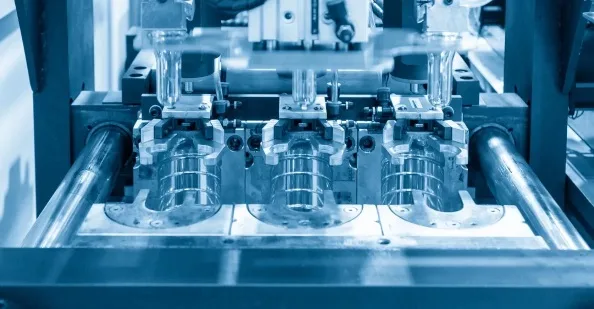

Plastic injection molding has transformed India’s manufacturing sector by revolutionizing the production of plastic products. This process involves injecting melted plastic into a mold to create intricate shapes with precision and efficiency. Leading injection molding companies in India are driving industry progress through advanced technologies, sustainable practices, and innovative designs. In addition to improving the quality and variety of plastic products, these companies are also contributing to India’s economic growth. This article will explore some of the top 5 companies that have revolutionized the Indian plastic injection molding industry.

1. SSI MOULDS – Sunshine Industries (India)

SSI Moulds is part of Sunshine Industries India, renowned for the manufacture and supply of plastic components, specializing in plastic injection molding. Since its establishment in 1992, the company has amassed over 22 years of expertise in delivering top-notch plastic products to a wide range of industries, including automobile, home appliances, modular kitchens, electrical devices, and various other industrial sectors. SSI Moulds’ expertise includes creating rubber parts, injection-molded electronic device components, furniture hardware parts, vacuum-formed trays, and other custom plastic products. SSI Moulds offers in-house product and mold designing, enabling them to fulfill custom requirements with a wide range of options. They prioritize durability and longevity, ensuring that only the highest quality items are delivered to customers. SSI Moulds also offers thermoforming and vacuum forming products, such as PVC trays, food packing trays, blister packing products, and ABS cutlery trays.

Address: Delhi, India

Year Founded: 1992

Advantages: Offers in-house product and mold designing services and various plastic injection molding solutions including thermoforming and vacuum forming.

2. TDL Mould

Since its establishment in 1995, TDL Mould has emerged as a leading player in mold design, manufacturing, and plastic injection molding. With over 28 years of experience, the company has successfully extended its operations to India, sharing its state-of-the-art technology and a team of skilled engineers to assist local businesses with advanced plastic injection molding solutions. TDL Mould provides large-scale production of plastic injection molding. To maintain both cost-effectiveness and superior quality, the company has chosen to manufacture in China instead of Europe, where energy costs are high. TDL serves various industries such as consumer electronics, automotive interior trim, and precision medical devices. The company demonstrates its dedication to quality through its ISO8 cleanroom production specifically designed for the medical industry. They use stainless steel molds that adhere to SPI-SPE standards. In addition, the company offers a wide range of post-production services, such as surface finishing, ultrasonic welding, hot melt welding, and product assembly. TDL Mould takes a methodical approach to plastic injection molding. They carefully select the materials, create precise molds, and control the injection process. This guarantees that every product surpasses the industry standards. With a solid presence in India and a dedication to quality and innovation, the company has become a valuable partner in the plastic processing and manufacturing industry.

Website: https://tdlmould.com/

Year Founded: 1995

Advantages: Specializes in large-scale production of plastic injection molded components for various industries including the automotive, medical and consumer electronics.

3. Tech Plaastic Industries (TPI)

Tech Plaastic Industrie (TPI) is a renowned plastic injection molding company that provides a wide array of services. The company has expertise in injection molding, compression molding, thermoset injection molding, and mold design & manufacturing. Being a one-stop shop, the company takes complete accountability for projects, managing all stages from design to production. TPI has earned IATF 16949 and ZED certifications demonstrating their dedication to quality management, improvement, defect prevention, and waste reduction in the supply chain. The company’s objective is to meet customer requirements in an efficient and effective manner while also striving for Zero Defect production processes. TPI offers an extensive selection of plastic injection molding machines ranging from 50T to 650T. With this capability, TPI is able to serve clients across all stages of their assemblies. To ensure seamless production, TPI also has captive power generators in place to prevent any interruptions. The company has an in-house tool room that can design and produce molds based on customer designs. These molds include hot runner, un-screwing, and collapsible core molds. Their team of qualified quality engineers carries out layout inspections to ensure the highest quality standards for our custom injection molds. TPI works with various types of plastics, including both commodity plastics and engineering plastics like TPE.

Address: Irungattukottai, Tamil Nadu, India

Year Founded: 1975

Advantages: Offers various plastic injection molding services including compression molding, thermoset injection molding, and mold design & manufacturing.

4. India Plastic Machinery

India Plastic Machinery, located in Delhi, is a popular manufacturer and exporter specializing in plastic injection molding. Since its establishment in 2016, the company has rapidly gained recognition in the industry and achieved an impressive annual turnover of Rs. 2 – 5 Crore. India Plastic Machinery is a company that provides various products and services related to plastic injection molding. They offer a range of machines, including Injection Molding Machines, 3 Phase Injection Molding Machines, Used Injection Molding Machines, and Vertical Injection Moulding Machines. They also provide Electric Hopper Dryers, Mild Steel Twin Screw Barrels, Vertical Colour Mixing Machines, and Electric Vacuum Loaders. This wide selection of products showcases India Plastic Machinery’s ability to meet the diverse needs of the plastic molding industry. India Plastic Machinery is known for their commitment to quality and customer satisfaction. They provide Injection Molding Machine Repairing Services, ensuring that clients receive comprehensive support and maintenance. The company has adopted a customer-centric approach, prioritizing solutions tailored to their clients’ specific needs. Their expertise in handling new and used injection molding machines establishes them as a dependable and versatile partner within the plastic injection molding industry.

Address: Puth Khurd, Delhi, India

Year Founded: 2016

Advantages: Offers a wide range of plastic injection molding machines, both new and used

5. Pragati Plast Moulds

Pragati Plast Moulds, based in Ahmedabad, Gujarat, India, is a reputable manufacturer, trader, and supplier in the field of plastic injection molding. The company has established itself as a trustworthy entity in the industry, specializing in the manufacturing of various types of plastic molds and dies. The company’s product range is extensive and includes Injection Moulds, Die Blow Mould, Die Injection Moulded, Die Manufacturer, Die Moulding Plastic, Die Plastic Household Goods, Die Plastic Spoon, Disposable Plastic Spoon Mould, Food Container Plastic Mould, Household Article Plastic, Plastic Mould, and Spoon Mould. These products are manufactured with strict adherence to industry norms, ensuring they meet the high-quality standards expected in the market. Pragati Plast Moulds is renowned for its commitment to delivering exceptional quality. The company meticulously designs and produces its products in strict accordance with industry standards. This unwavering focus on quality is a key advantage for Pragati Plast Moulds, establishing it as a trustworthy partner for businesses seeking top-notch plastic injection molds and dies.

Address: Ahmedabad, Gujarat, India

Year Founded: 2011

Advantages: Is a manufacturer and supplier of a wide range of plastic injection molds and dies

Conclusion

The plastic injection molding industry in India has experienced significant growth. Leading companies like SSI Moulds, TDL Mould, India Plastic Machinery, Pragati Plast Moulds, and Tech Plaastic Industrie have played a crucial role in this development. They have introduced advanced technologies and promoted innovation, elevating India’s manufacturing capabilities. Through their production of high-quality plastic components, they have not only improved the country’s manufacturing sector but also established India as a strong contender in the global market. The combined efforts of these top companies highlight the dynamic and ever-evolving nature of India’s plastic injection molding industry.